A method of manufacturing a camera bracket

A manufacturing method and camera technology, which are applied in the coating and other directions, can solve the problems of high surface treatment defect rate, no positioning structure, low efficiency, etc., and achieve the effects of high punching precision, improving production efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

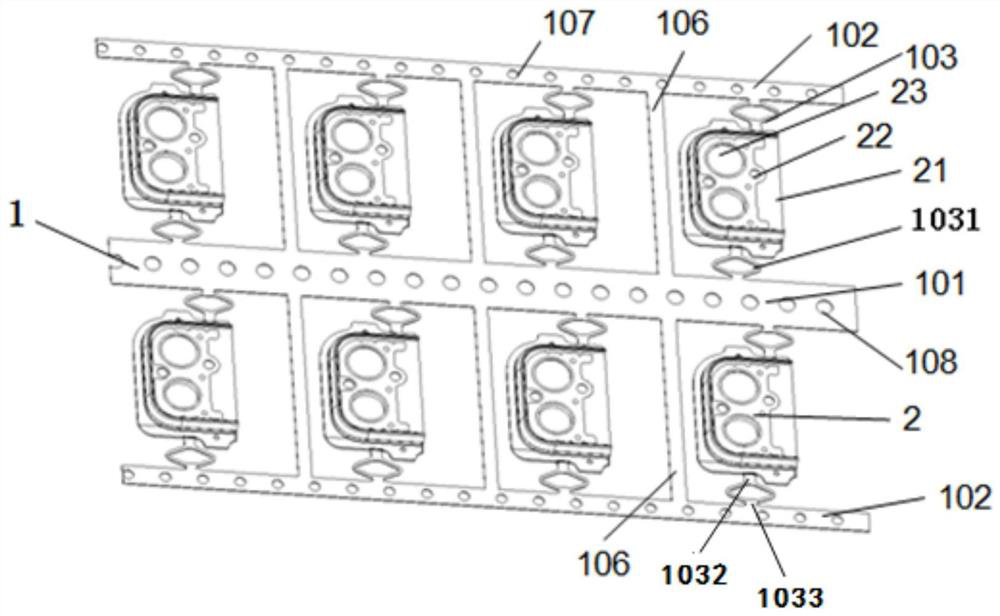

[0018] like figure 1 As shown, the manufacturing method of the camera bracket of the present embodiment includes the following steps: (1) manufacture the strip 1 containing the inlaid steel sheet 21 of the camera bracket 2 by stamping; (2) place the strip 1 Placed in the injection mold, the insulating plastic body of the camera bracket 2 and the inlaid steel sheet 21 are injection molded into one body by injection molding.

[0019] In the method for manufacturing the camera bracket of the present invention, the material strip 1 containing the inlaid steel sheet 21 is produced by stamping first, and then the material strip 1 is placed in an injection mold for injection molding, so that continuous batch production of injection molding can be realized, and the production process is simplified. , Improve production efficiency and reduce producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com