Automobile axle housing with side impact energy absorption structures

A technology of energy-absorbing structures and axle housings, applied in axles, wheels, vehicle components, etc., can solve problems such as poor safety, achieve good side impact resistance, and increase the effects of elements involved in energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

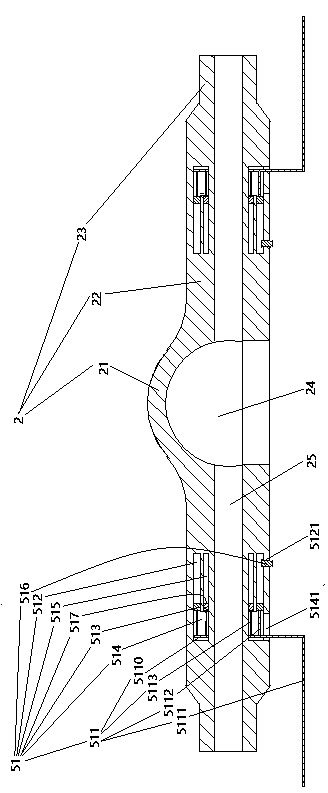

[0019] Embodiment one, see figure 1 , an automobile axle housing provided with a side impact energy-absorbing structure, comprising an axle housing 2.

[0020] The axle housing 2 is provided with a reducer installation section 21 and two axle shaft installation sections 22 located on both sides of the reducer installation section. The free end of the axle shaft mounting section 22 is provided with a wheel joint 23 . The reducer installation section 21 is provided with a reducer installation cavity 24 . The half-shaft installation section 22 is provided with a half-shaft installation channel 25 extending from the end surface of the wheel joint 23 along the extension direction of the half-shaft installation section and communicating with the reducer installation cavity. A side impact energy-absorbing structure 51 is arranged inside the half-shaft installation section 22 .

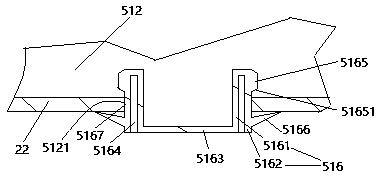

[0021] The side impact energy-absorbing structure 51 includes a drive frame 511 , a cylinder 512 , a co...

Embodiment 2

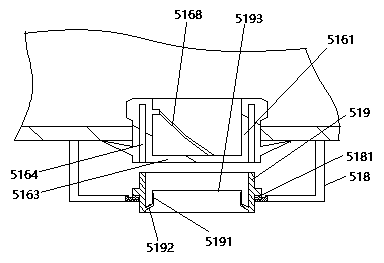

[0029] Embodiment two, the difference with embodiment one is:

[0030] see image 3 , the inner peripheral surface of the inner tube 5161 is provided with a vane 5168 that guides the sealing head 516 to rotate when the fluid flows through the inner tube. The half shaft installation section 22 is also provided with a support frame 518 . The supporting frame 518 is rotatably connected with a connecting sleeve 519 through a plane bearing 5181 . The connecting sleeve 519 is connected with an annular blade 5191 . A limiting portion 5192 is formed between the annular blade 5191 and the connecting sleeve 519 . The blade 5191 is provided with an annular cutting edge 5193 . The annular cutting edge 5193 is aligned with the bottom wall 5163 . The outer diameter of the blade 5191 is equal to the inner diameter of the inner circular tube 5161.

[0031] During use, if the sealing head 516 is ejected, before the annular cutting edge 5193 contacts the bottom wall 5163, the connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com