Anti-scalding paper-plastic container

A paper-plastic, anti-scalding technology, applied to drinking vessels, etc., can solve problems such as insufficient strength, softening of the main body 11 when heated, poor cooling effect, etc., and achieve improved heat insulation and anti-scald effects, and good heat insulation and anti-scald effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

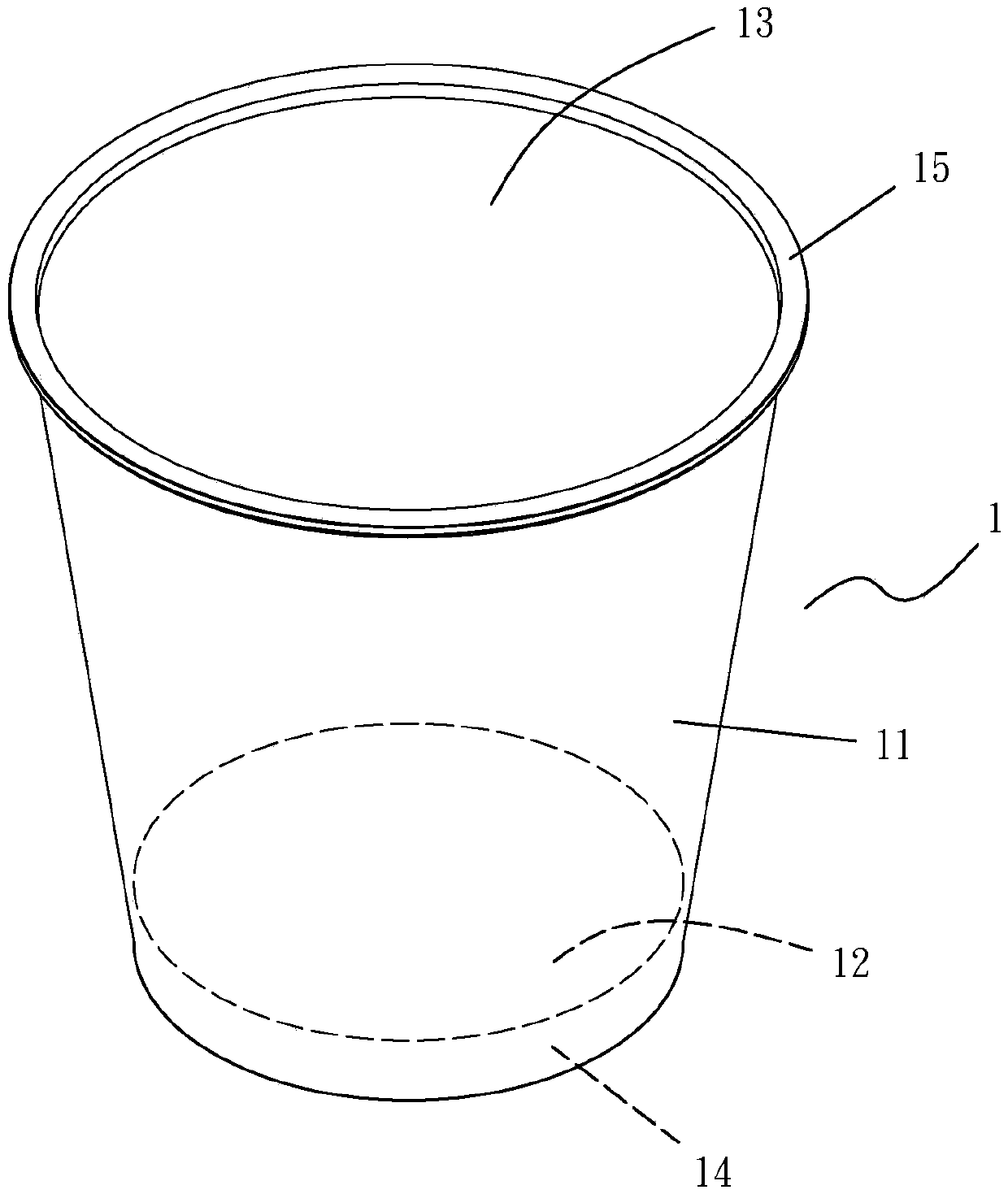

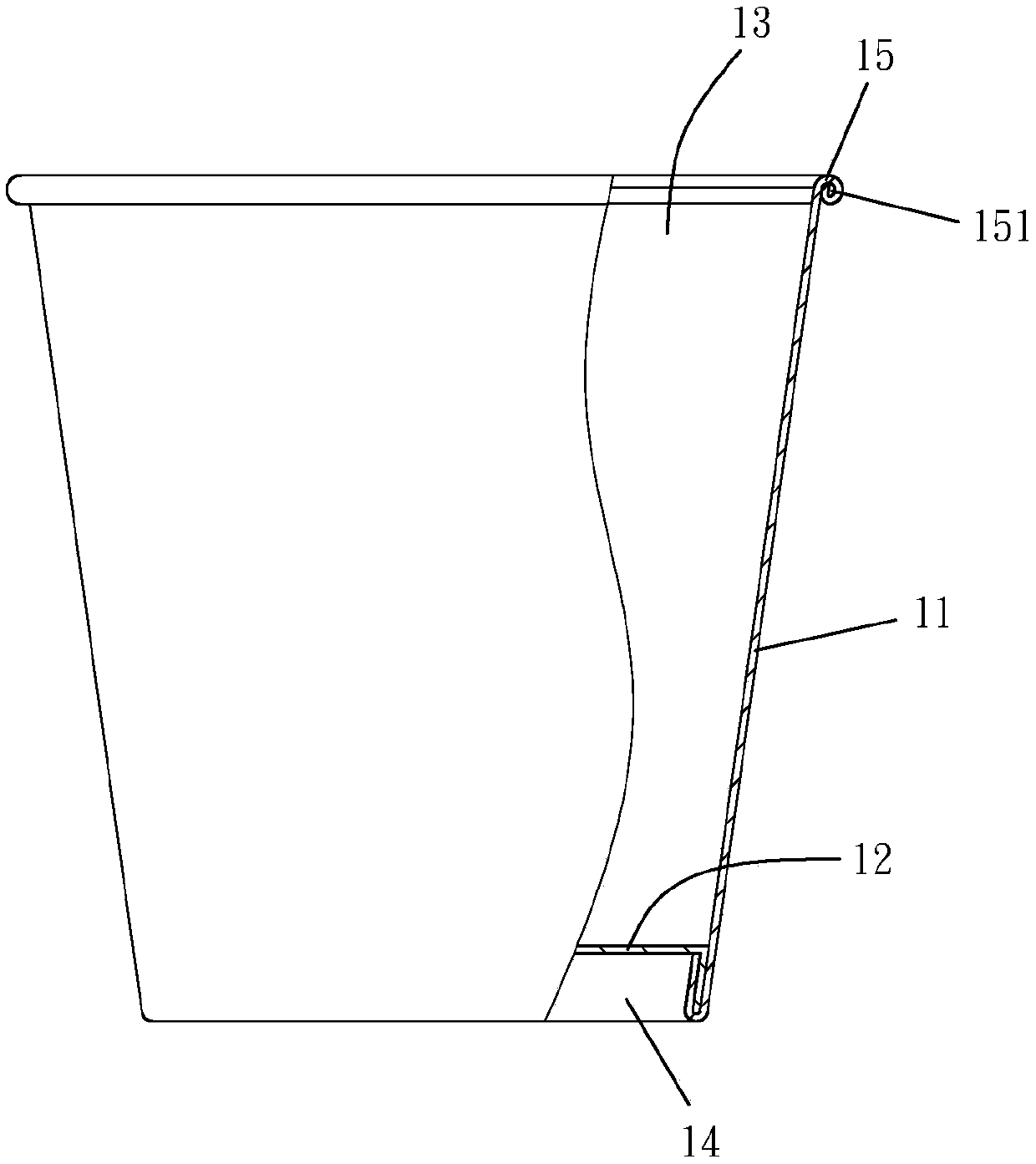

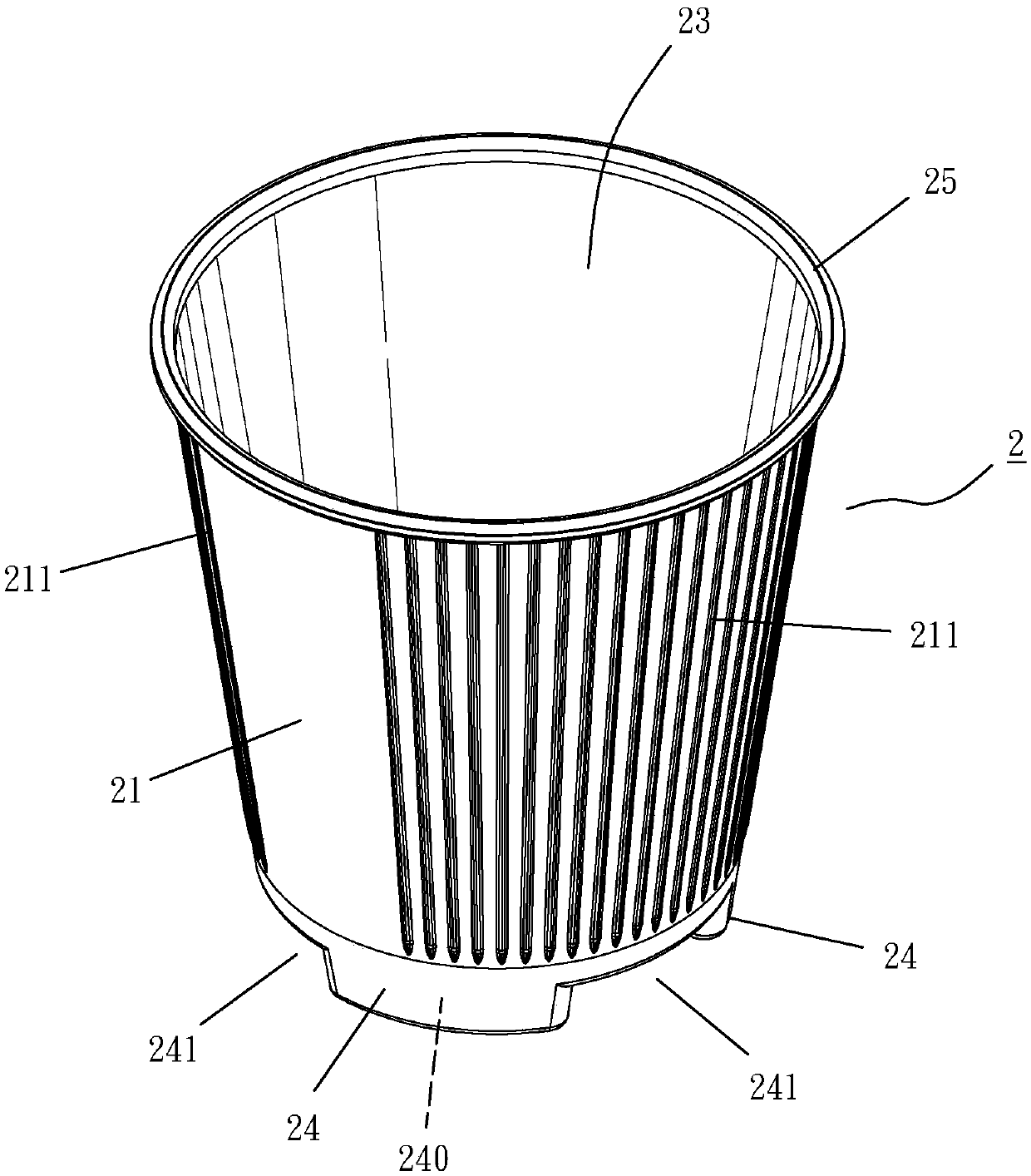

[0039] The embodiment of the present invention is an anti-scald paper-plastic container 2, the anti-scald paper-plastic container 2 is manufactured by the manufacturing technology of paper-plastic products, and the "manufacturing technology of paper-plastic products" referred to in general is based on The pulp fiber material and / or the plant fiber material are mixed and beaten to form a slurry material, which is injected into the slurry tank, and then enters the slurry tank from a slurry suction die to absorb slurry and adhere to a slurry layer, and the slurry layer is squeezed Press dehydration to become a primary product, and then the primary product is heat-pressed and shaped into a paper-plastic product. The paper-plastic product manufactured by the present invention through the "manufacturing technology of paper-plastic product" has a specific structure and usage, so it is called anti-scald paper-plastic container 2 .

[0040] see Figure 3-8 As shown, the anti-scalding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com