Feed inlet structure of vertical crusher

A technology of crusher and feed port, which is applied in the field of mining machinery, can solve the problems of low constraint strength and short service life of the mandrel, and achieve the effects of strengthening constraint strength, improving service life, and facilitating assembly and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

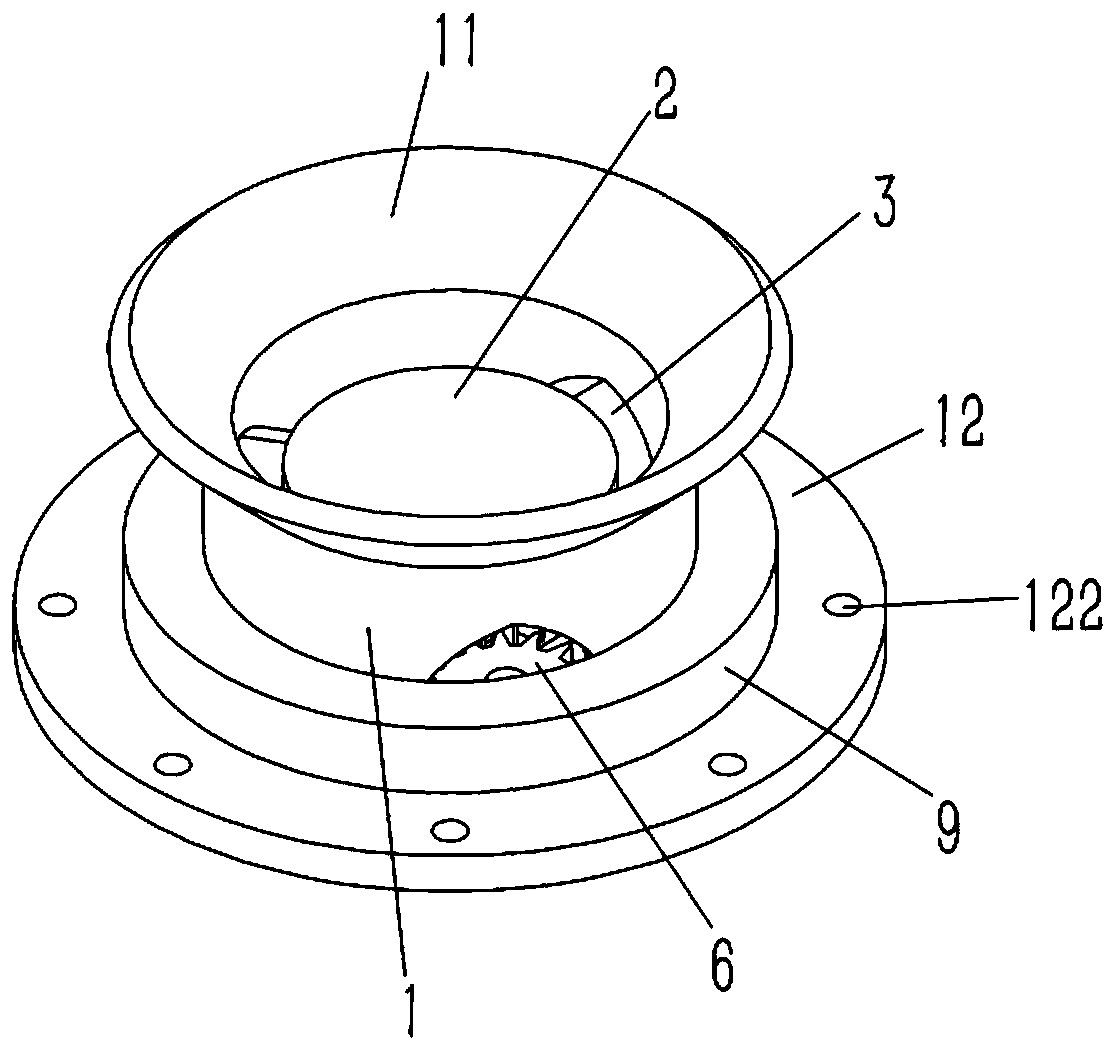

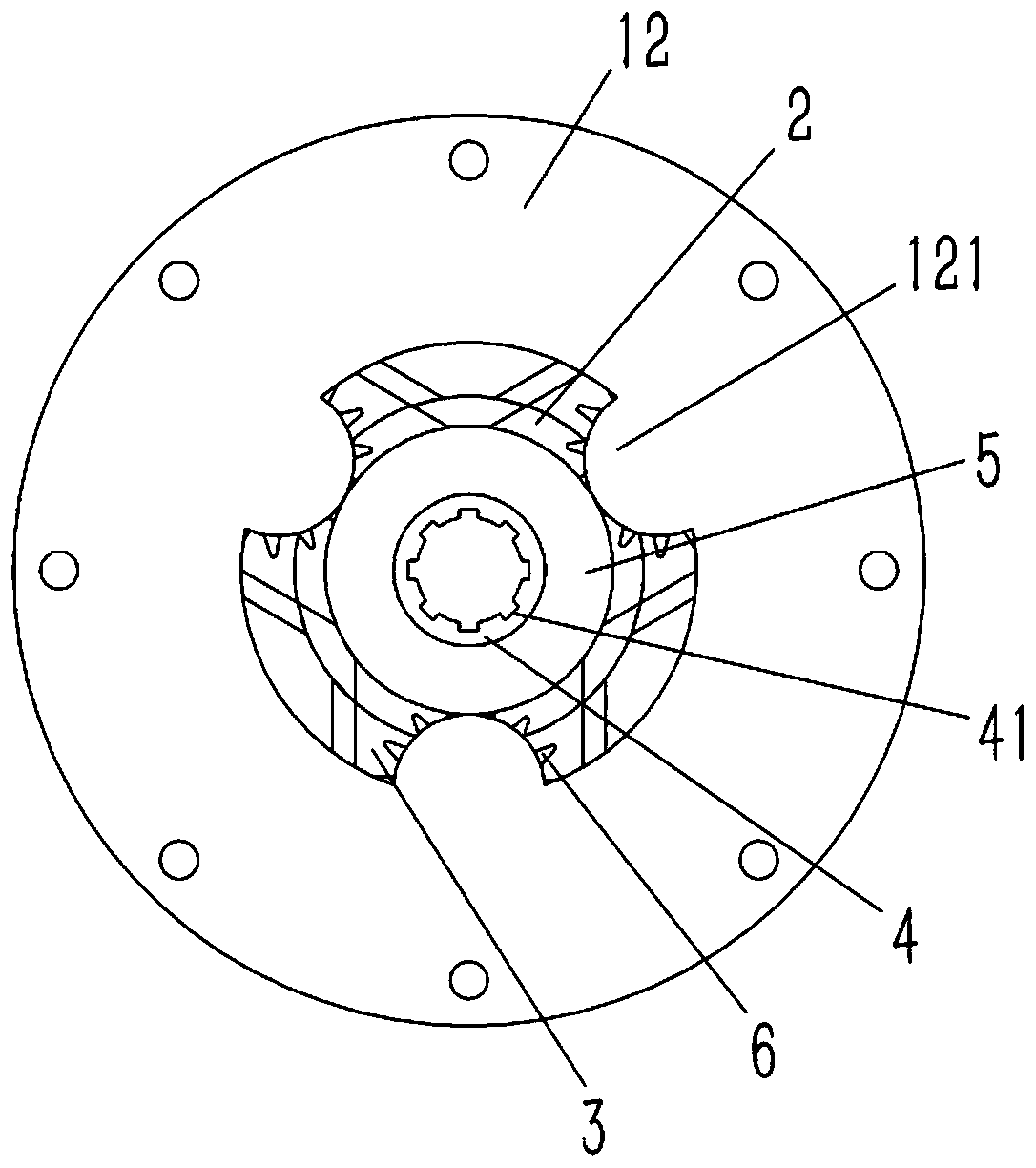

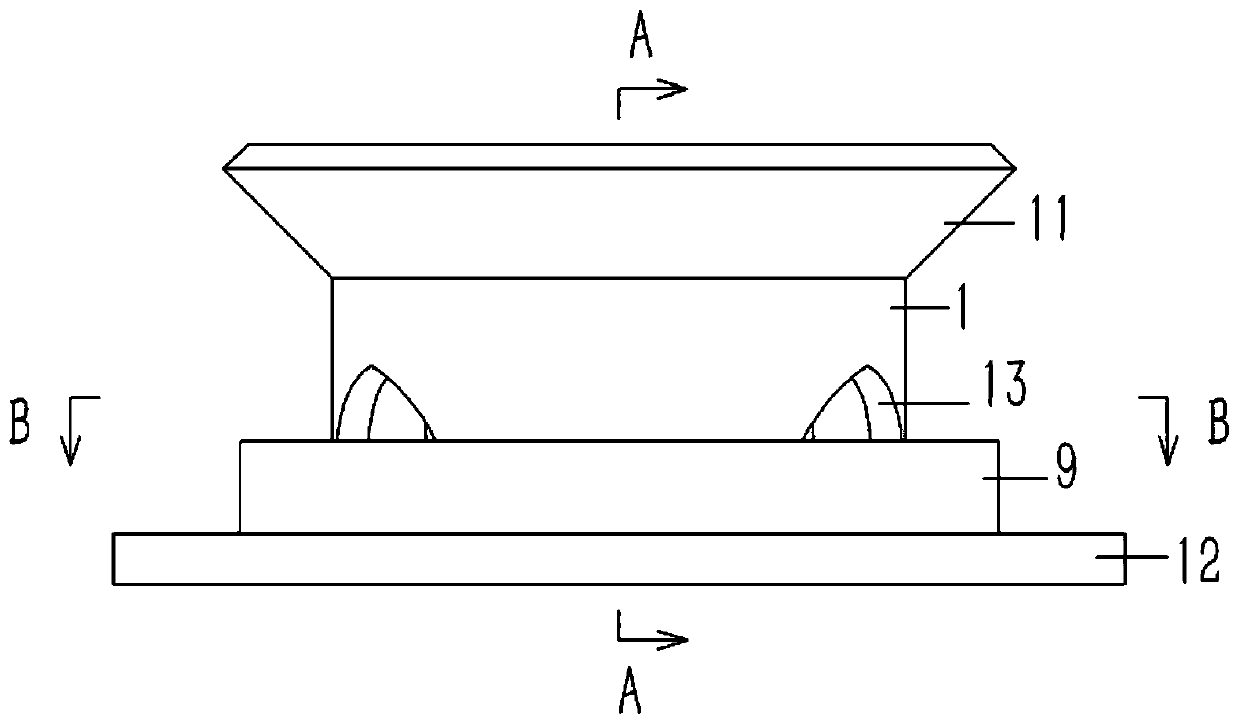

[0020] Example: see Figures 1 to 5 As shown, a feed inlet structure of a vertical crusher includes a feed cylinder 1, the lower end of the feed cylinder 1 is formed with a flange 12, and a conical shroud 2 is inserted in the feed cylinder 1 to guide the flow of water. There are several conical notches 21 formed on the side wall of the lower end of the cover 2, and several conical notches 13 opposite to the notches 21 are formed on the side wall of the lower end of the feeding cylinder 1. The barrel 1 is provided with several conical passages 3 connecting the notches 21 and the tapered notches 13. The inner ends of the conical passages 3 are fixed on the inner wall of the shroud 2, and the outer ends are fixed on the inner wall of the feeding barrel 1. ; The main gear 4 is inserted in the wind deflector 2, and the upper and lower end faces of the main gear 4 lean against an annular retaining ring 5, and the retaining ring 5 is fixed on the inner wall of the wind deflector 2; t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap