Overturning type automatic drilling machine for intelligent pantograph carbon sliding plate and drilling method of overturning type automatic drilling machine

A pantograph carbon slide, flip-type technology, applied in the direction of drilling/drilling equipment, boring/drilling, mechanical equipment, etc., can solve the problems of inconvenient collection, low work efficiency, distance error, etc., to achieve collection Cleaning, improving work efficiency, and reducing the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

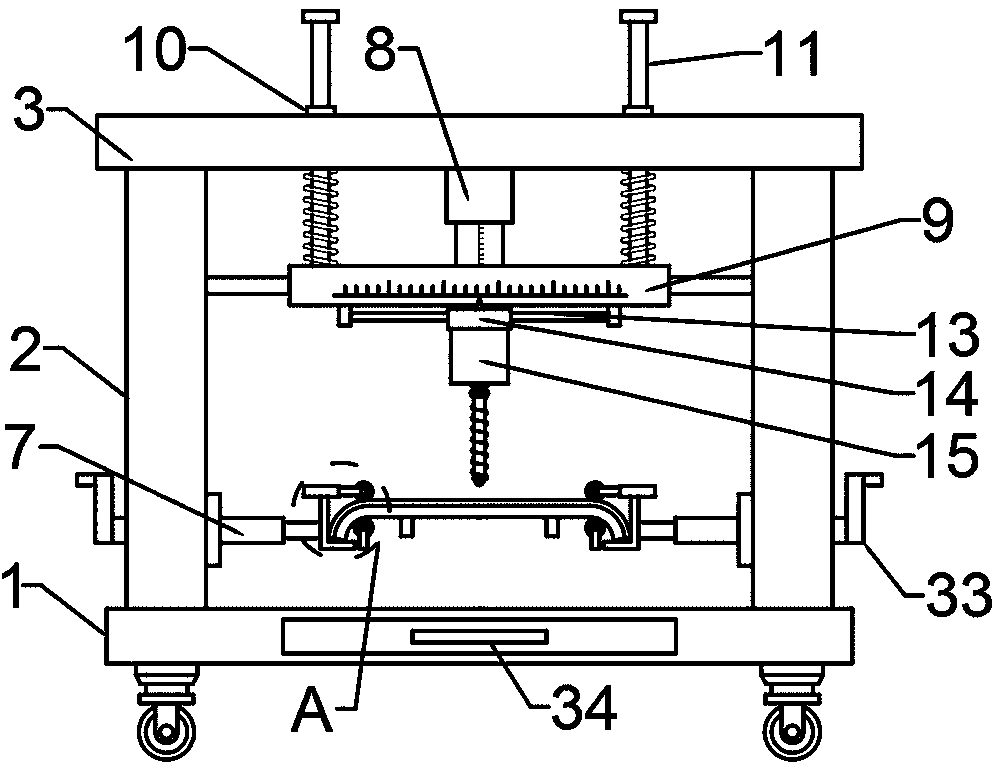

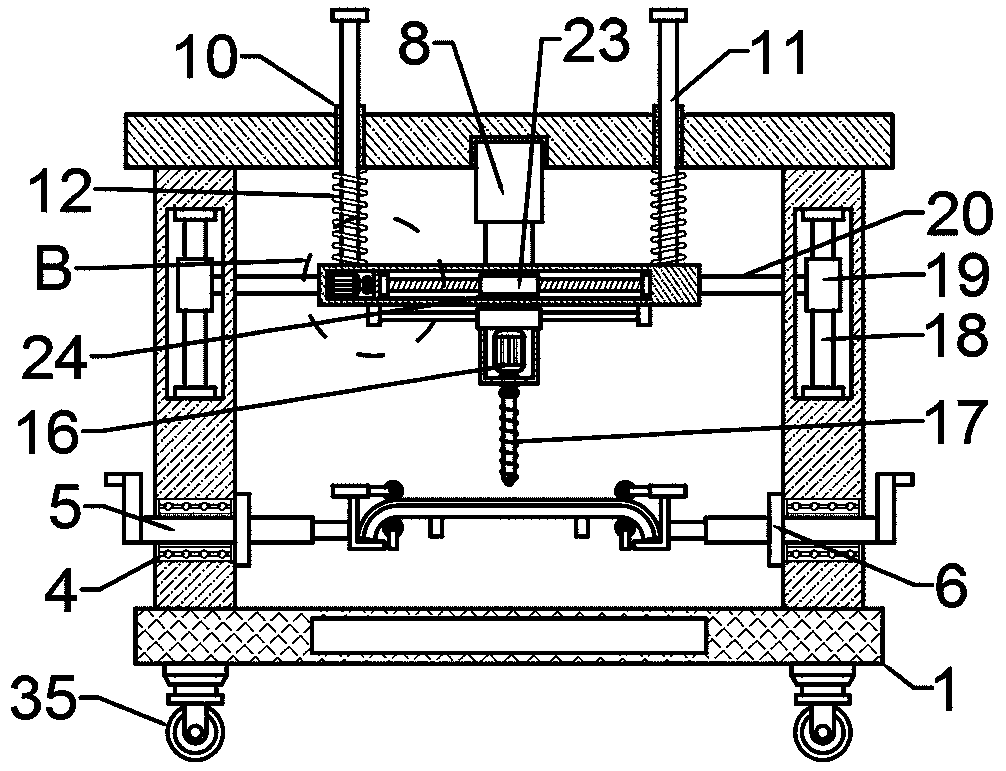

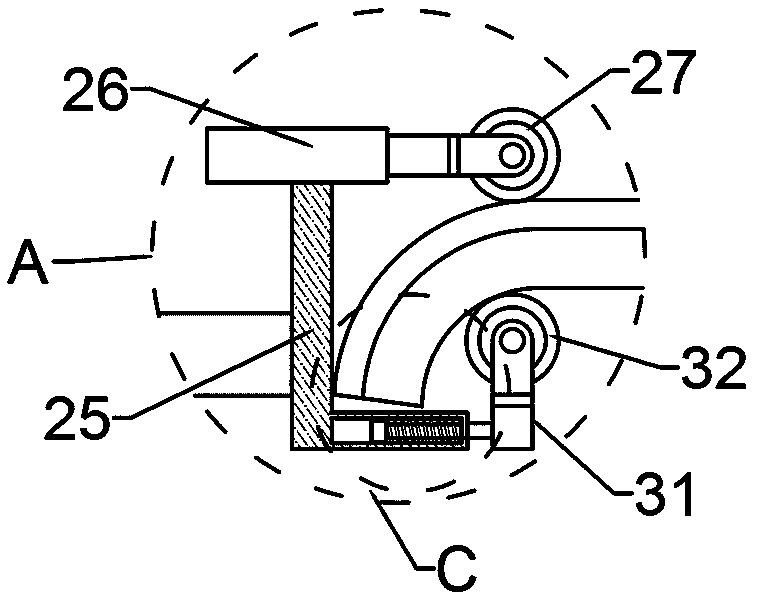

[0028] Embodiment 1: see Figure 1-6 , a flip-type automatic drilling machine for intelligent pantograph carbon skateboards, including a base 1, the base 1 is a rectangular plate-shaped horizontally arranged, and vertical The set support column 2 is fixedly installed with a horizontal beam 3 on the top of the support column 2; a circular bearing groove is opened transversely on the outer side of the lower column of each of the support columns 2. The first bearing 4 that is axially consistent with the bearing groove is fixedly installed in the bearing groove, and a horizontally arranged rotating rod 5 is fixedly installed in the inner ring of each of the first bearings 4. The inner end of the rotating rod 5 is fixedly equipped with a vertically arranged mounting plate 6, and the outer surface of each of the mounting plates 6 is fitted with the inner surface of the support column 2; in each of the mounting plates 6 The middle part of the side is fixedly installed with the first...

Embodiment 2

[0033] Example 2: see Figure 7 , in the present embodiment, the present invention also proposes a drilling method for an intelligent pantograph carbon slide plate with a flip-type automatic drilling machine, comprising the following steps:

[0034] Step 1: First, the first telescopic rod 7, the cylinder 8, the first motor 16, the second motor 21 and the second telescopic rod 26 are electrically connected to the external power supply through wires, and the staff controls and fixes the hole to be punched through the clamping assembly. Carbon skateboard bracket;

[0035] Step 2, by controlling the expansion and contraction of the first telescopic rod 7, the L-shaped fixed plate 25 is pressed against the two ends of the bracket, and the lower pinch roller at the top of the rectangular bar 31 is driven by the round rod 29 under the elastic force of the return spring 30 32 is clamped on the bending part of the inner arc surface of the bracket, and the upper pressure roller 27 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com