Efficient puncher for garment fabric processing

A puncher and fabric technology, applied in metal processing and other directions, can solve problems such as easy wrinkles, inaccurate positioning, and easy slippage of fabrics, so as to improve punching efficiency, ensure accuracy, and prevent punching position errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

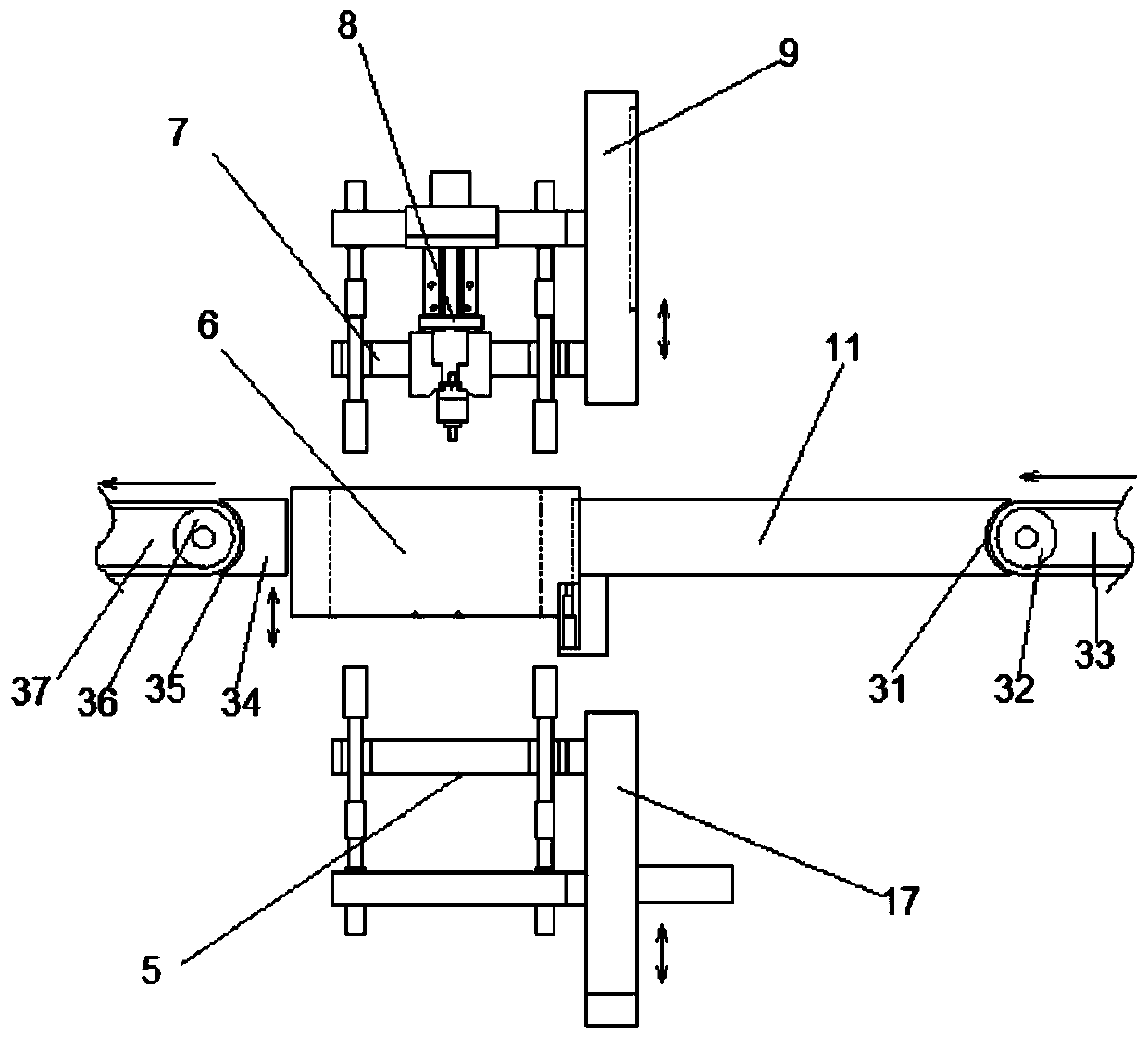

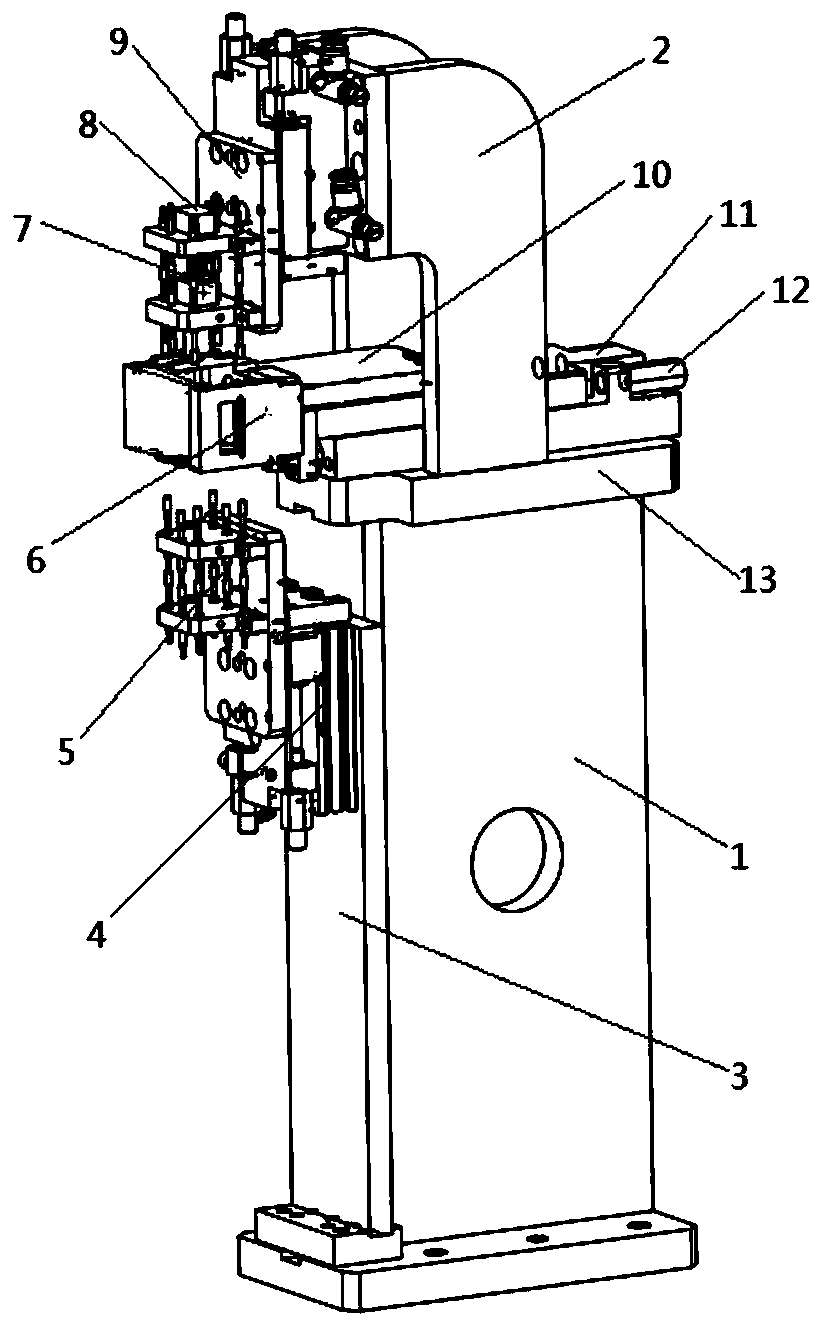

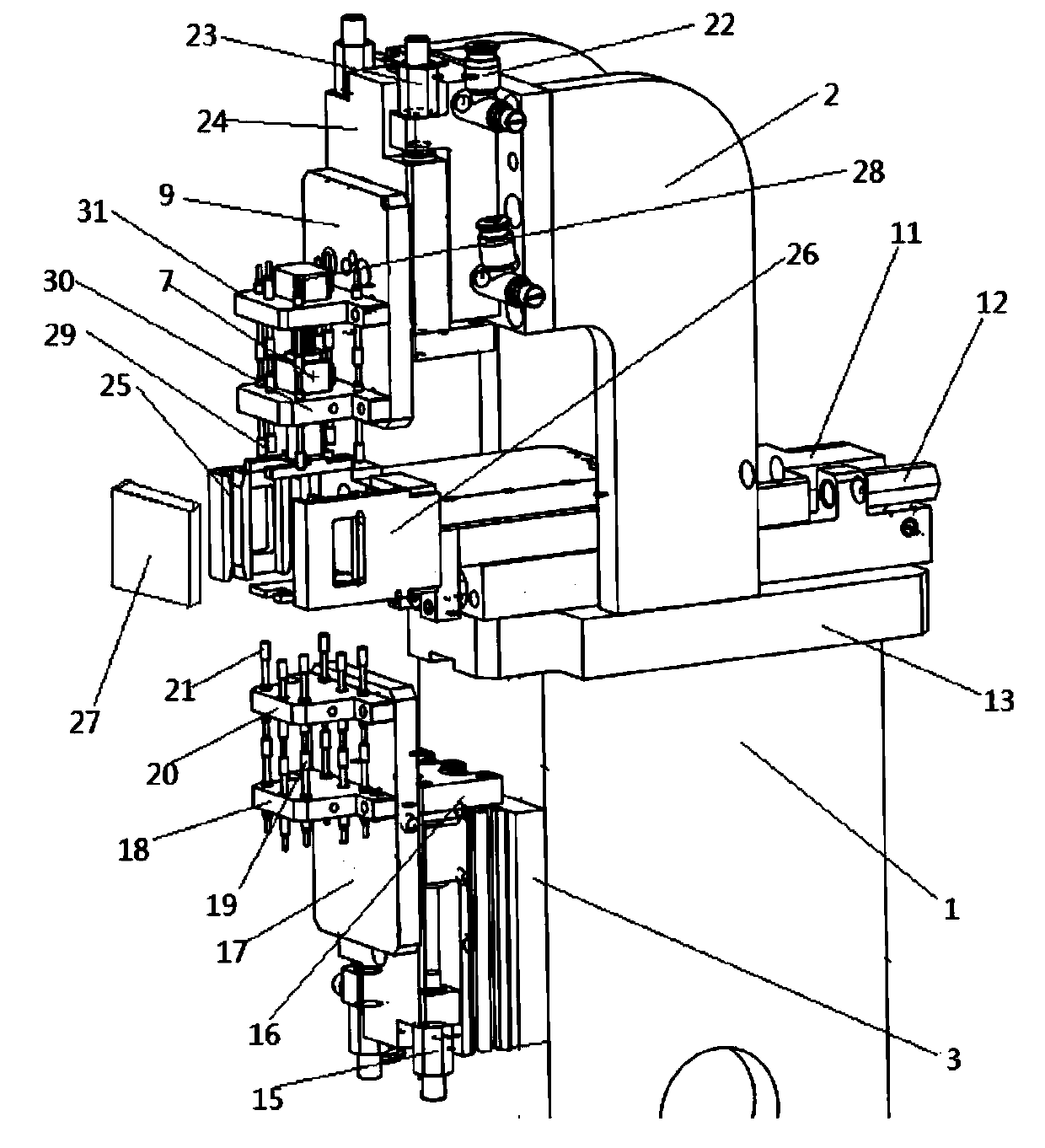

[0025] see Figure 1~4 , in an embodiment of the present invention, a high-efficiency puncher for garment fabric processing includes a machine base 1, a head frame 2, a lower positioning mechanism 5, an upper positioning mechanism 7, a punching head 8, an upper lifting mechanism and a lower positioning mechanism. Lifting mechanism 4, wherein, described machine base 1 is extended vertically, and the top of described machine base adopts installation platform 13 to be fixedly provided with described nose frame, and one side of described machine base is provided with described upper lift The mechanism is characterized in that the output end of the upper lifting mechanism is provided with the upper lifting seat plate 9, and the punching head 8 extending downward is installed on the upper lifting seat plate 9;

[0026] The upper positioning mechanism 7 is arranged around the punching head 8, and the lower positioning mechanism 7, which is driven by the lower lifting mechanism 4, is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap