Production line of printed circuit board

A printed circuit board and production line technology, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problem of low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

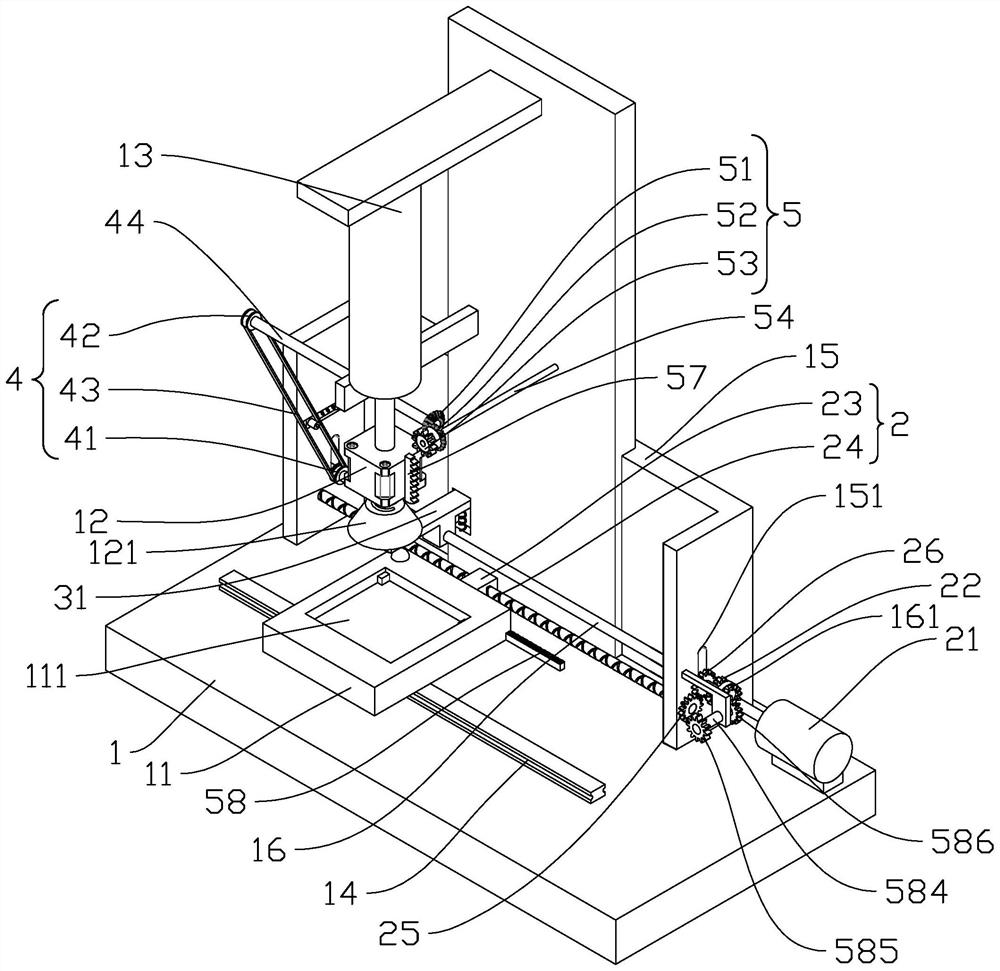

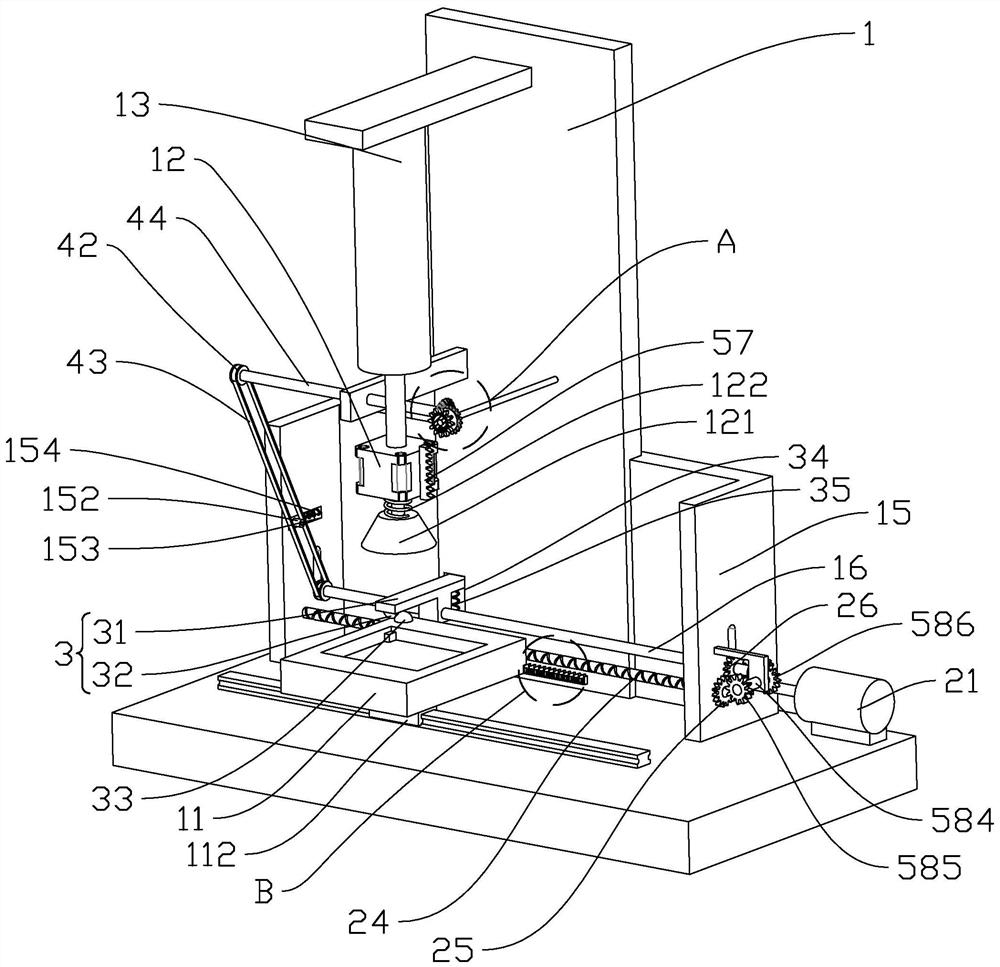

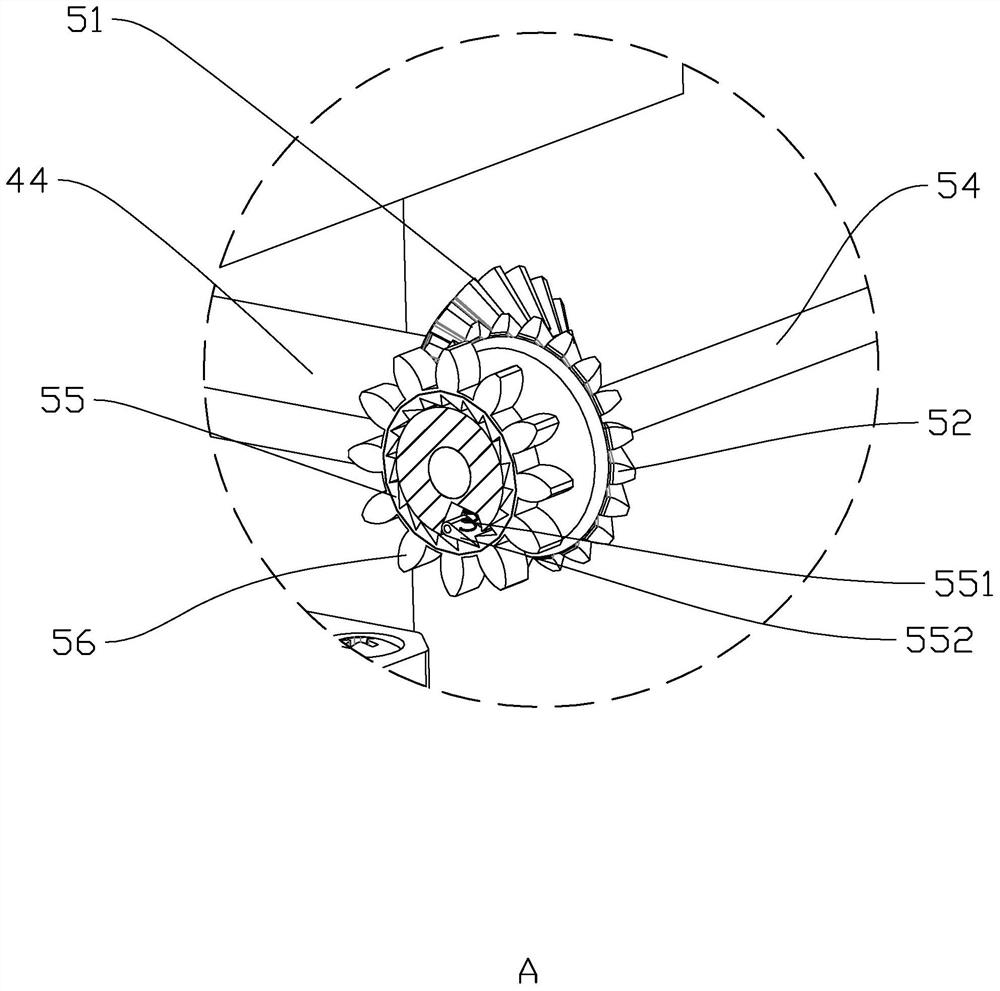

[0032] Attached to the following Figure 1-4 This application will be described in further detail.

[0033] The embodiment of the present application discloses a production line of a printed circuit board. refer to figure 1 , the production line of printed circuit boards includes a rack 1 , a workbench 11 and a mounting seat 15 .

[0034] refer to figure 1 as well as figure 2 , the rack 1 and the workbench 11 are arranged horizontally, and the mounting seat 15 is fixedly connected to the rack 1 . A slide rail 14 is fixedly connected to the rack 1, a slide rod 112 is fixedly connected to the bottom surface of the worktable 11, and the end of the slide rod 112 away from the worktable 11 is slidably connected to the slide rail 14, and the worktable 11 is provided with a place for placing the printed circuit board. Groove 111 . A cylinder 13 is vertically arranged on the frame 1 , the cylinder 13 is fixedly connected to the frame 1 , and a drilling machine 12 is fixedly con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap