Experimental method for measuring mechanical properties of metal by using indentation tester

An experimental method, the technology of the indenter, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of data errors, inaccurate judgments, and inability to unload loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

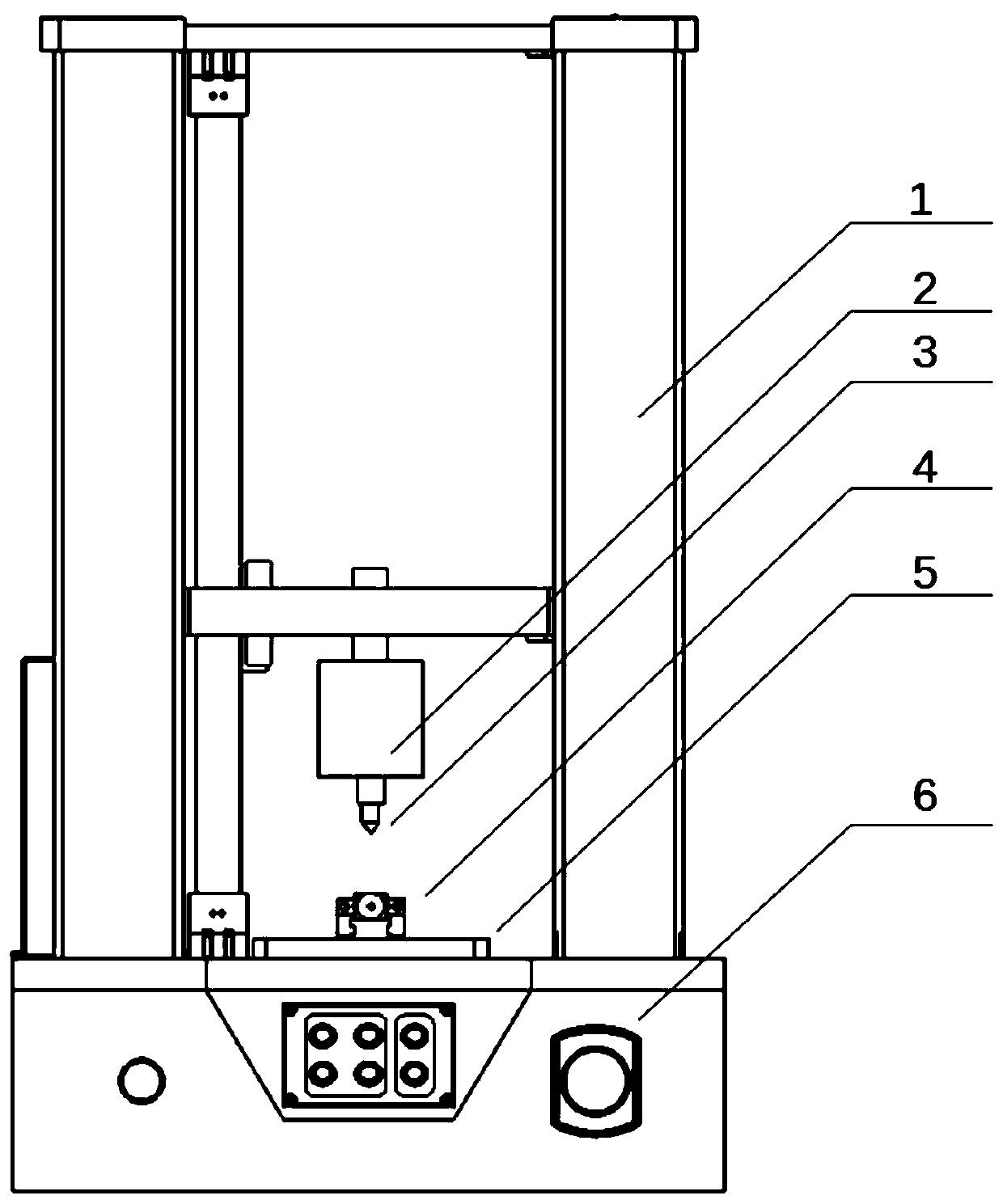

[0066] Such as Figure 1-6 As shown, an experimental method using an indenter to measure the mechanical properties of metals, the specific steps are as follows:

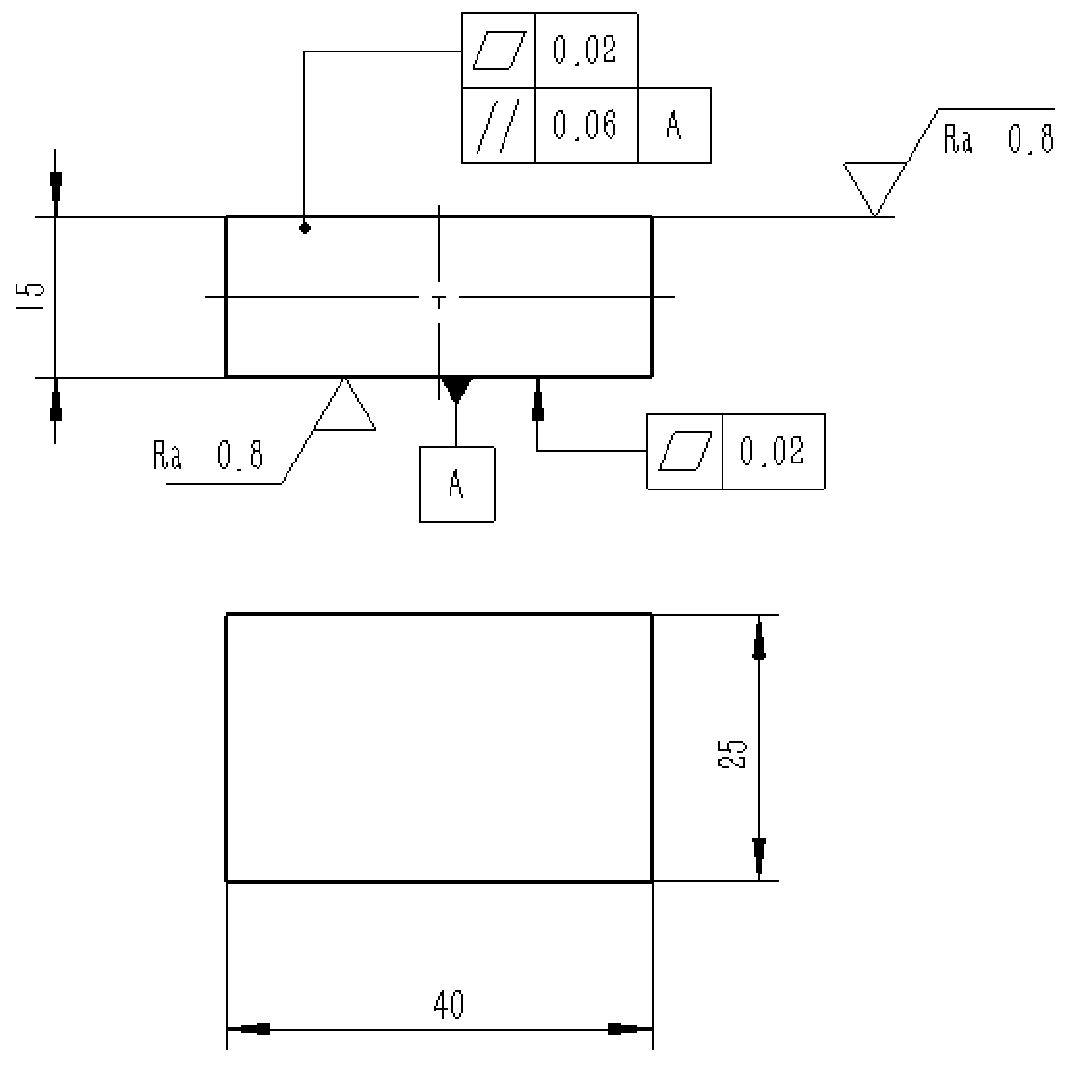

[0067] Step 1. First, prepare the sample of the indenter. The sample size of the metal Q345 is 40*25*15 (mm), and there are certain parallelism and flatness requirements. The specific requirements are as follows: image 3 shown;

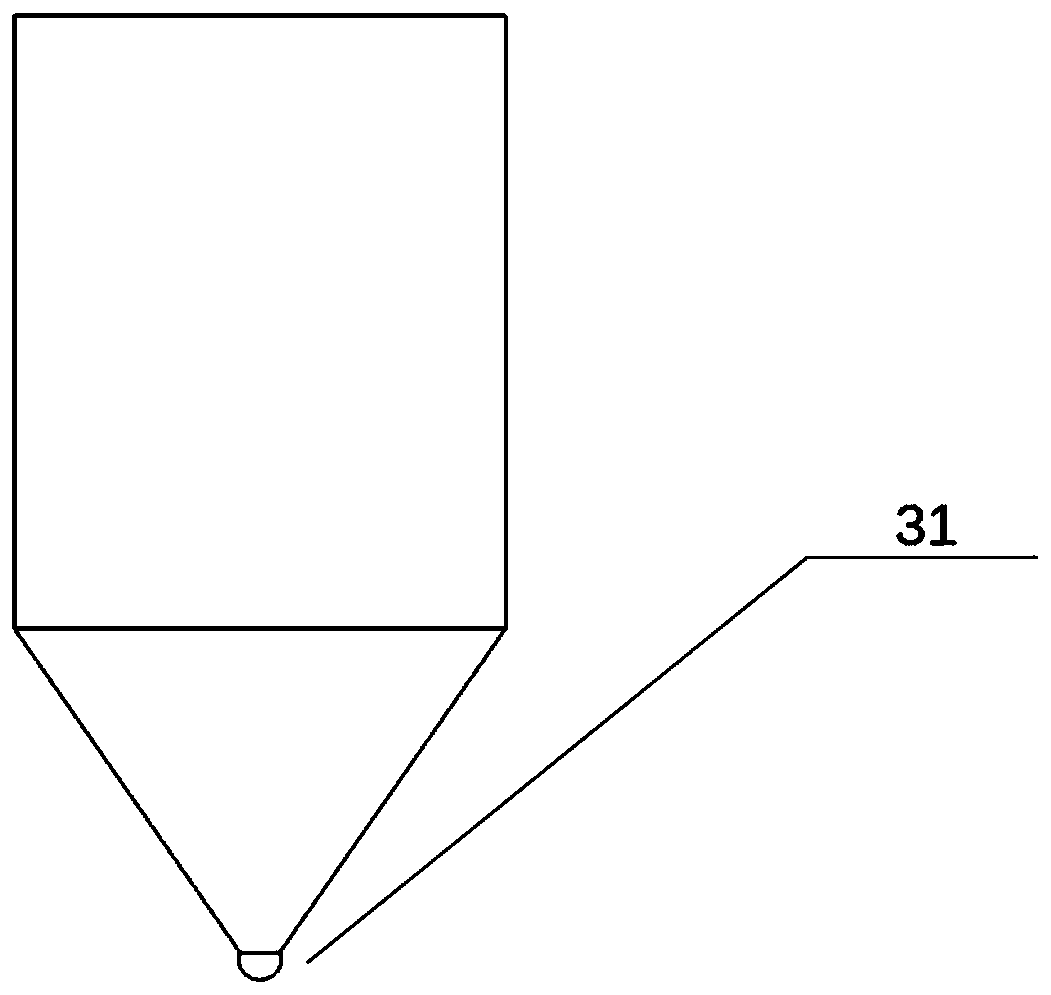

[0068] Step 2. Remove the spherical test head of the indenter, install the flat-bottomed test head, and remove the indenter fixture from the console;

[0069] Step 3. Before the Q345 indentation test, measure the mechanical error of the indentation test:

[0070] 3.1 In the indenter control system, set the depressing speed of the test head of the indenter to V 0 , V 0 =3mm / min;

[0071] 3.2 During the measurement process, it is necessary to carry out ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap