Bolt defect space positioning method based on multi-view geometry

A technology of spatial positioning and bolts, applied in image data processing, biological neural network models, instruments, etc., can solve the problems of difficult acceptance, inaccurate judgment, and irregular overlapping of photos, so as to improve the quality of acceptance and avoid manual missed inspection the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

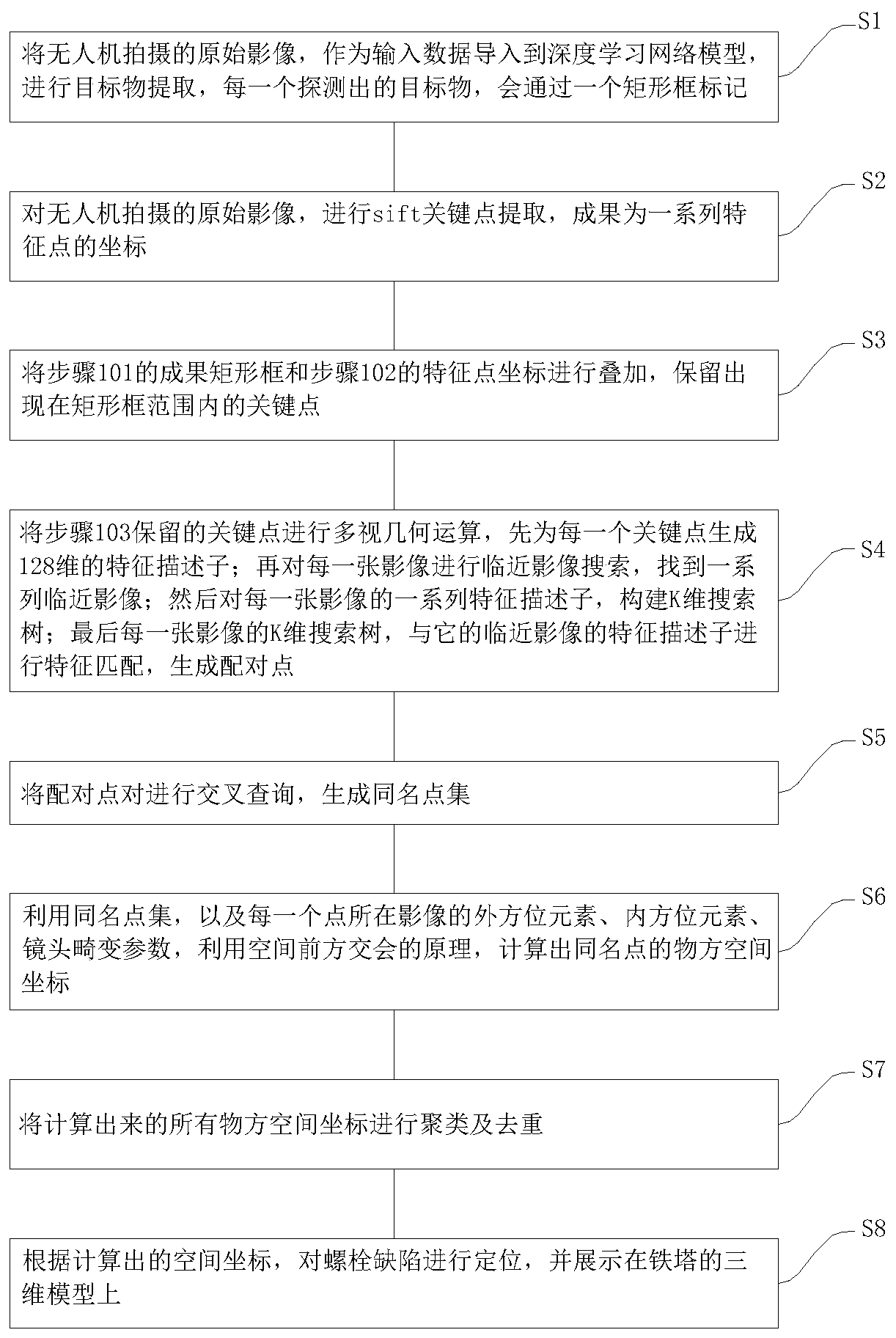

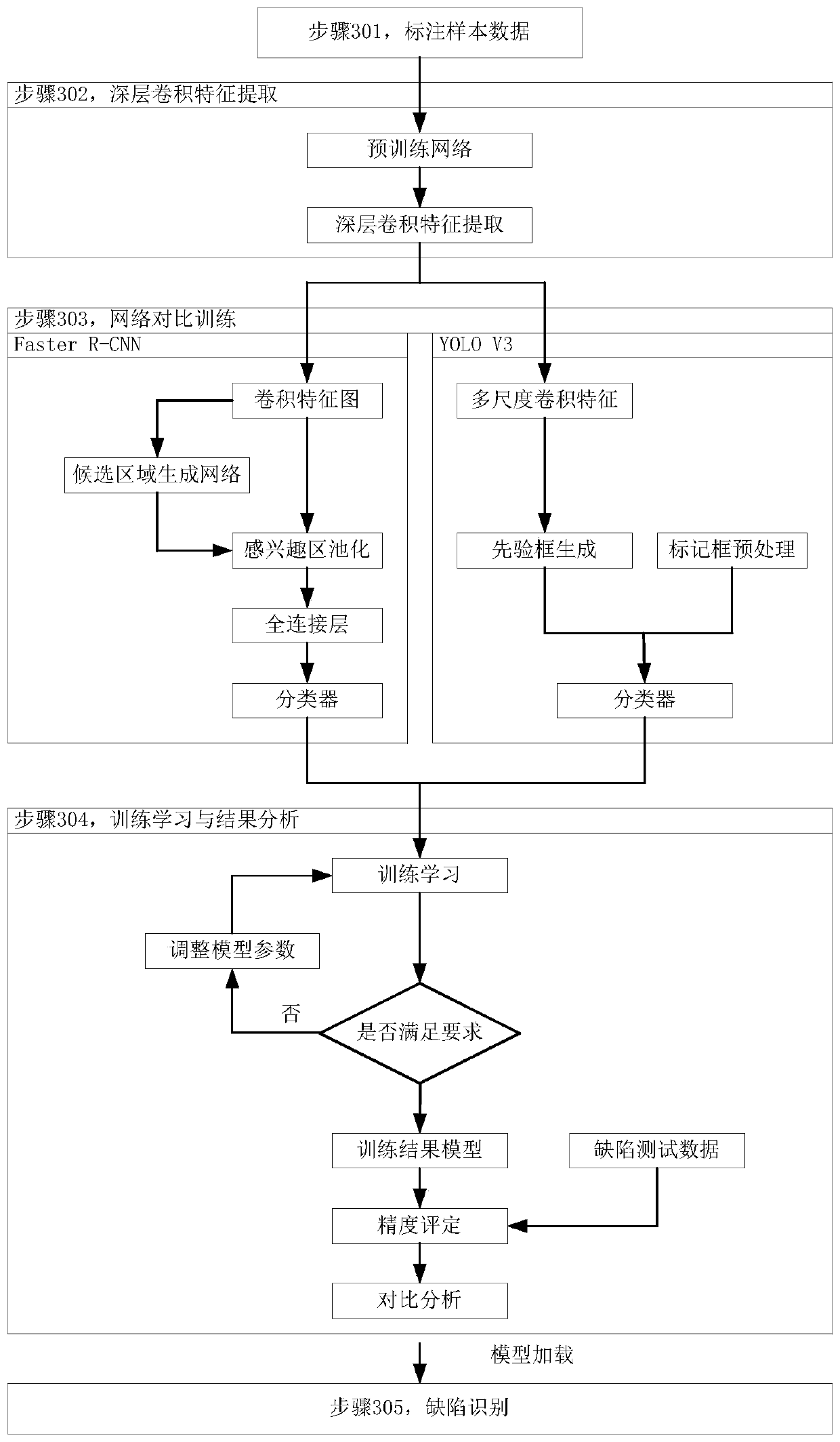

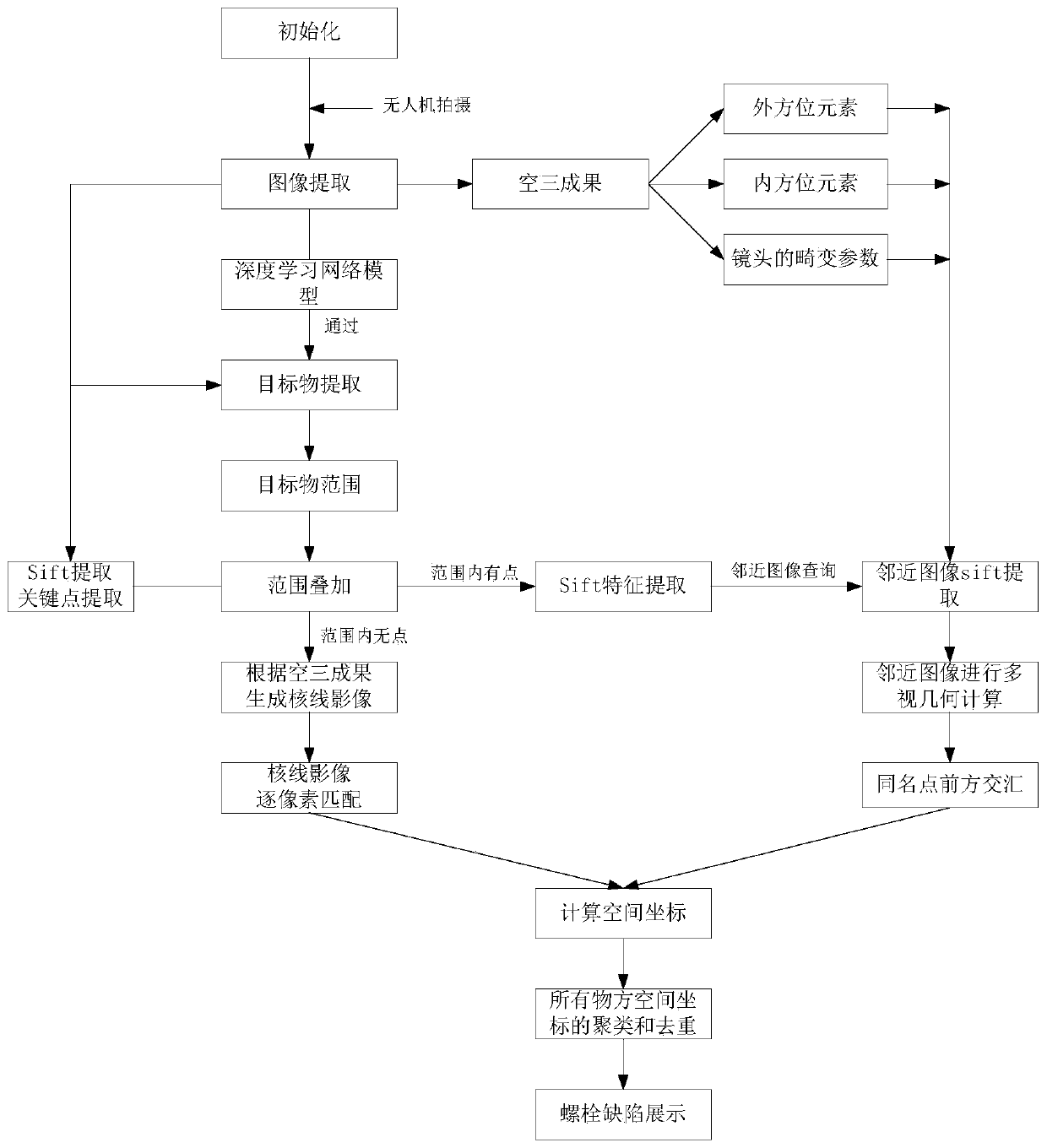

[0046] The described method for spatial positioning of bolt defects based on multi-view geometry, such as figure 1 , achieved through the following steps:

[0047] Step S1, importing the original image taken by the UAV into the deep learning network model as input data for target extraction, and each detected target will be marked by a rectangular frame;

[0048] Step S2, extracting Sift key points from the original image taken by the drone, and the result is a series of coordinates of feature points;

[0049] The Sift key point extraction adopts the Sfit algorithm, and the essence of the Sfit algorithm is to search for key points (feature points) on different scale spaces, calculate the size, direction, and scale information of the key points, and use these information to form key points to feature points Describe the problem.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com