Liquid cooling plate and liquid cooling device

A liquid-cooled plate, liquid-cooled technology, applied in electrochemical generators, electrical components, circuits, etc., can solve problems such as bulky volume, affecting the performance of battery modules, and complex piping design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

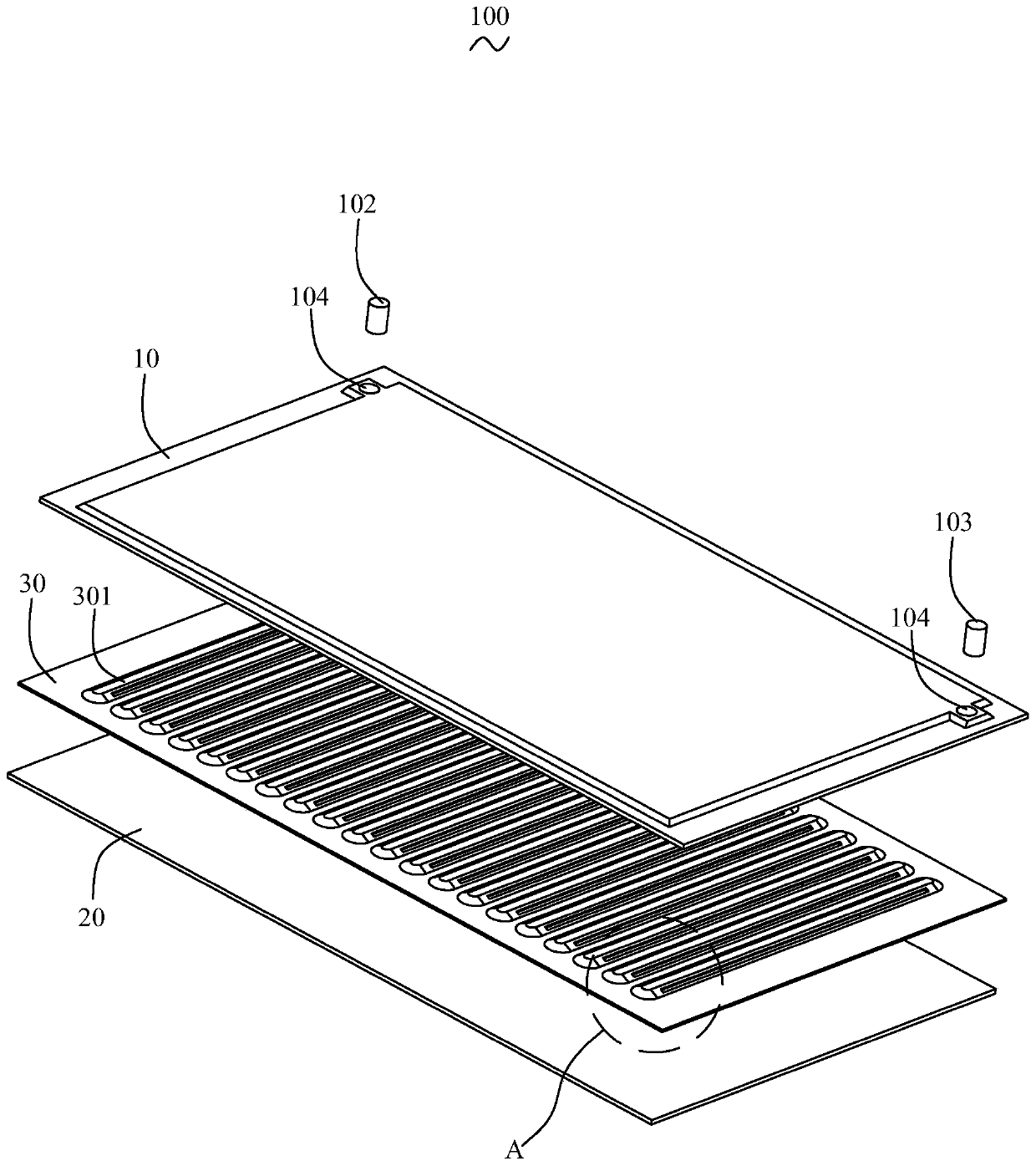

[0026] see Figure 1 to Figure 4 , the present invention provides a liquid cooling plate 100 and a liquid cooling device using the liquid cooling plate 100, which are mainly used to improve the cooling effect of the cooling liquid.

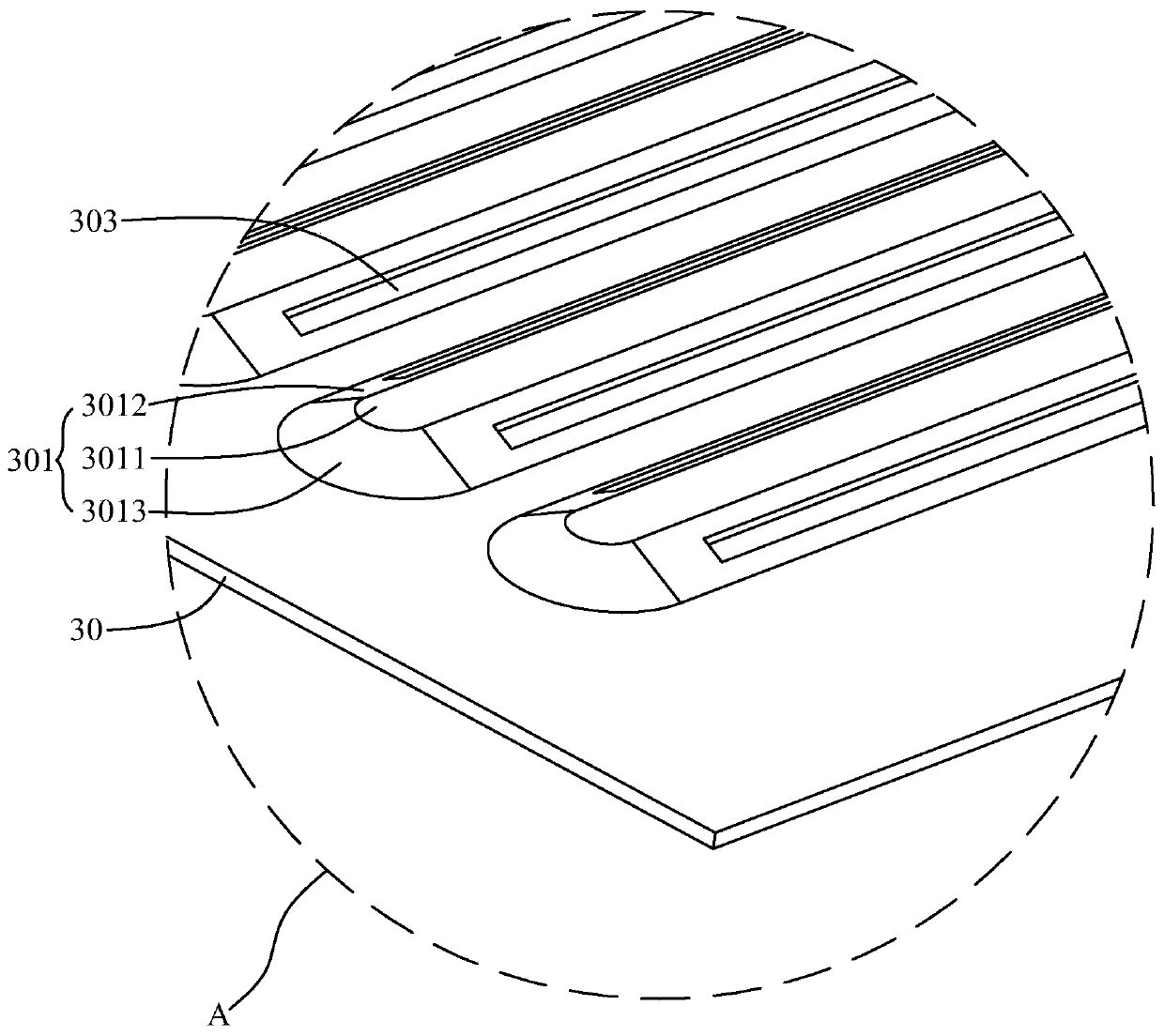

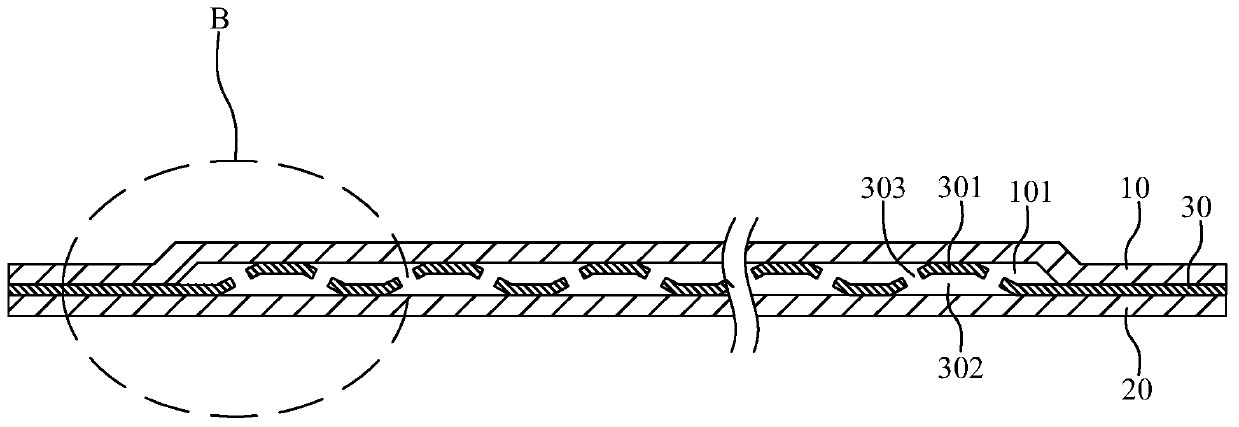

[0027] In an embodiment of the present invention, the liquid cooling plate 100 includes an upper plate 10, a lower plate 20, and a middle plate 30 connected between the upper plate 10 and the lower plate 20; the side of the upper plate 10 close to the middle plate 30 is formed by stamping The installation groove 101, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap