One-mold forming injection mold for automobile AB column decoration with covering

A technology for injection molding and column decoration, which is applied to household components, household appliances, and other household appliances. It can solve the problems of large cost investment, large equipment investment, and low processing efficiency, so as to improve production efficiency, reduce investment costs, and solve problems. The effect of the bubble problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

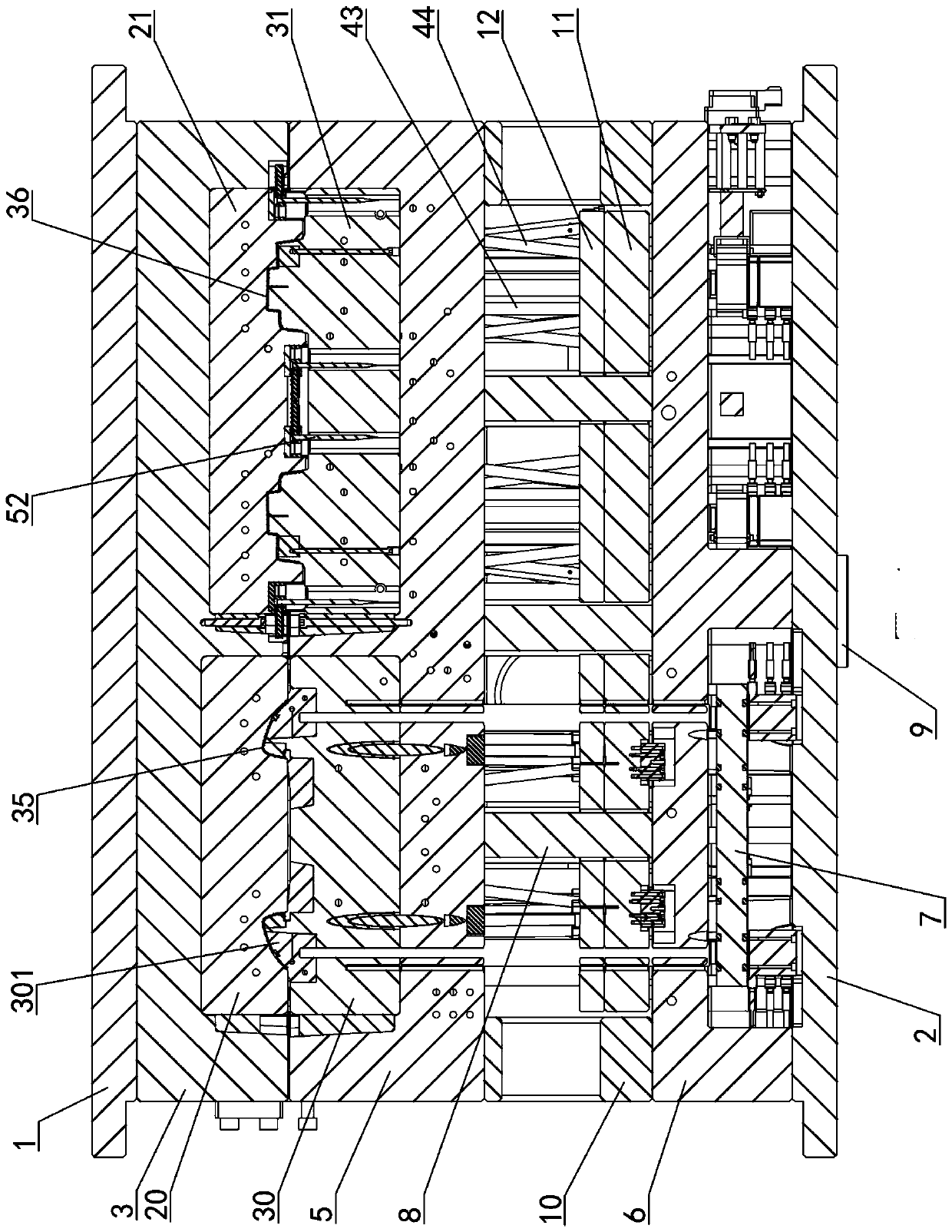

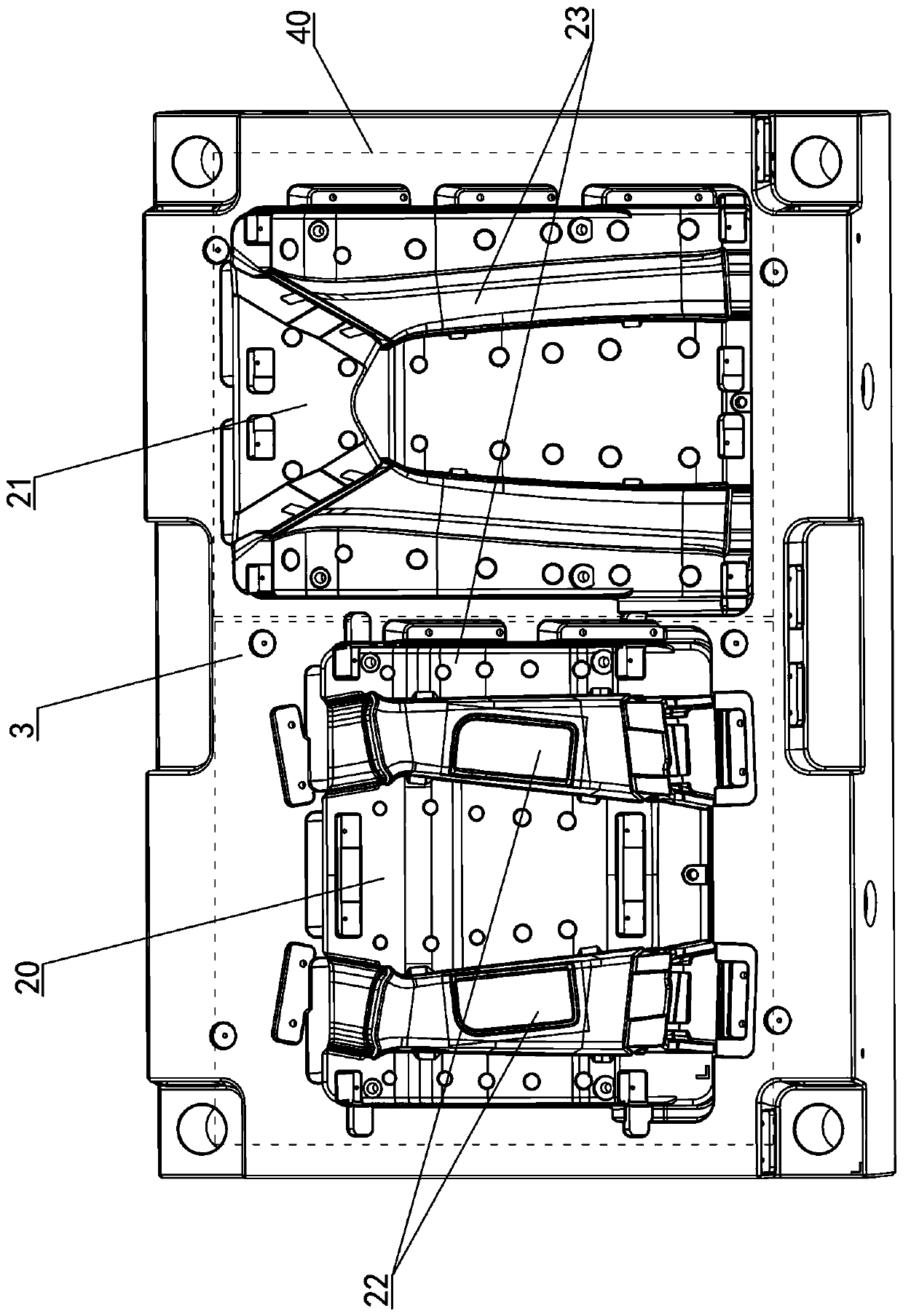

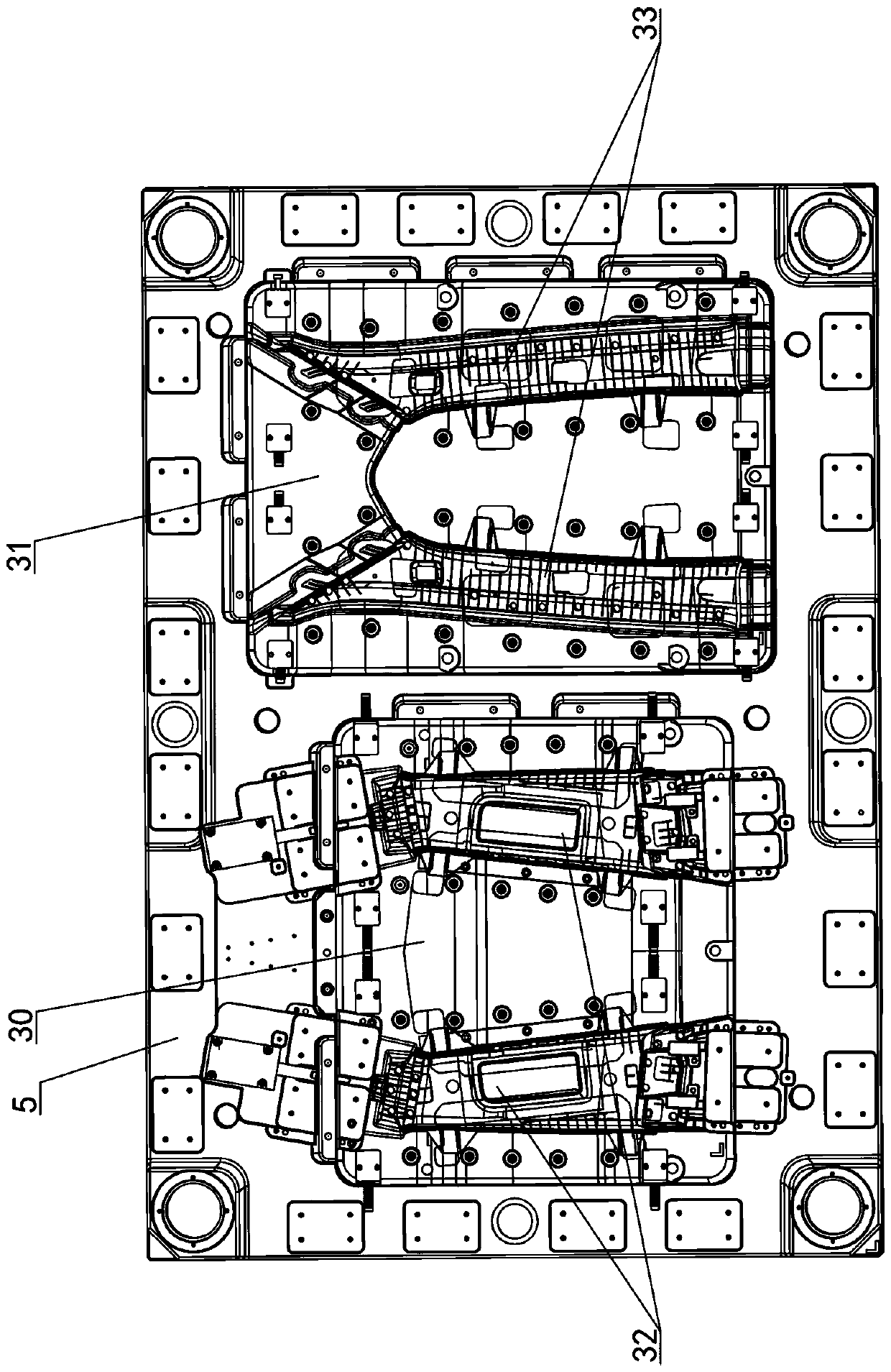

[0015] The present invention relates to a kind of molding injection mold of the automobile AB pillar trim with cloth, such as figure 1 — Figure 4 As shown, it includes the fixed mold doubler plate 1 and the movable mold doubler plate 2, the fixed mold frame 3 is installed under the fixed mold doubler plate 1, the fixed mold insert is set in the fixed mold frame 3, and the movable mold frame 5 is set on the movable mold doubler plate 2 , a movable mold insert is set in the movable mold frame, a hot runner frame 6 is installed on the movable mold doubler plate 2, a hot runner plate 7 is installed in the hot runner frame, a hot nozzle 8 is connected to the hot runner plate, and the movable mold doubler plate 2 The gate 9 is set in the center, the gate is connected to the hot runner plate 7 and the hot nozzle 8, the pad 10 is installed on the periphery of the hot runner frame 6, the movable mold frame 5 is fixed on the pad 10, and the lower top plate 11 and the An upper top plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com