Strength detection device for tunnel wall construction

A strength detection and wall technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems such as unstable fixation, difficult control, and angle deflection of the rebound hammer, so as to omit the work of measuring the area and make the line more convenient. selected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

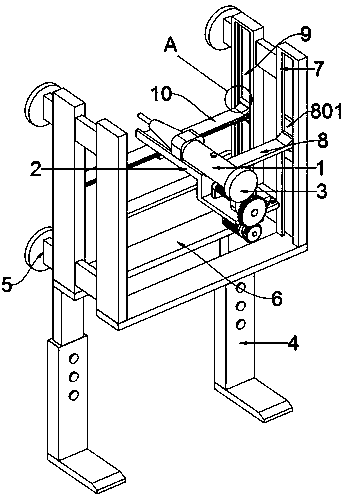

[0032] as attached figure 1 to attach Figure 9 Shown:

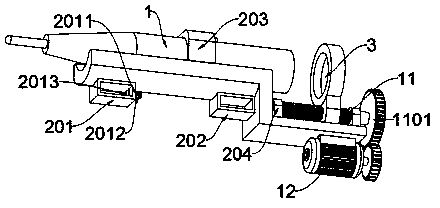

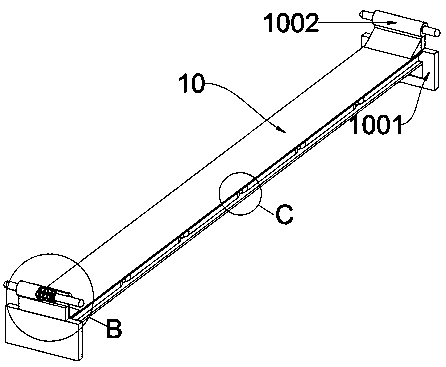

[0033] The invention provides a strength detection device for tunnel wall construction, comprising a rebound rebound meter 1, a mounting seat 2, a top cover 3, a foot 4, a positioning seat 5, a height adjustment frame 7, a horizontal adjustment frame 8, an adjustment screw 11, and a motor 12 The mounting base 2 is movably connected above the horizontal adjustment frame 8, and the mounting base 2 is also movably connected above the horizontal scale frame 10, and the lower surface of the mounting base 2 is fixedly connected with a front slide frame 201 ahead, and the front slide frame 201 There is a rear carriage 202 welded at the rear of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com