Power transmission cable video line patrol method and terminal

A transmission line and video technology, applied in the field of electronic information, can solve the problems of low inspection frequency, manual control, and no overall view, and achieve the effects of high line inspection efficiency, smooth movement process, and smooth zoom process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

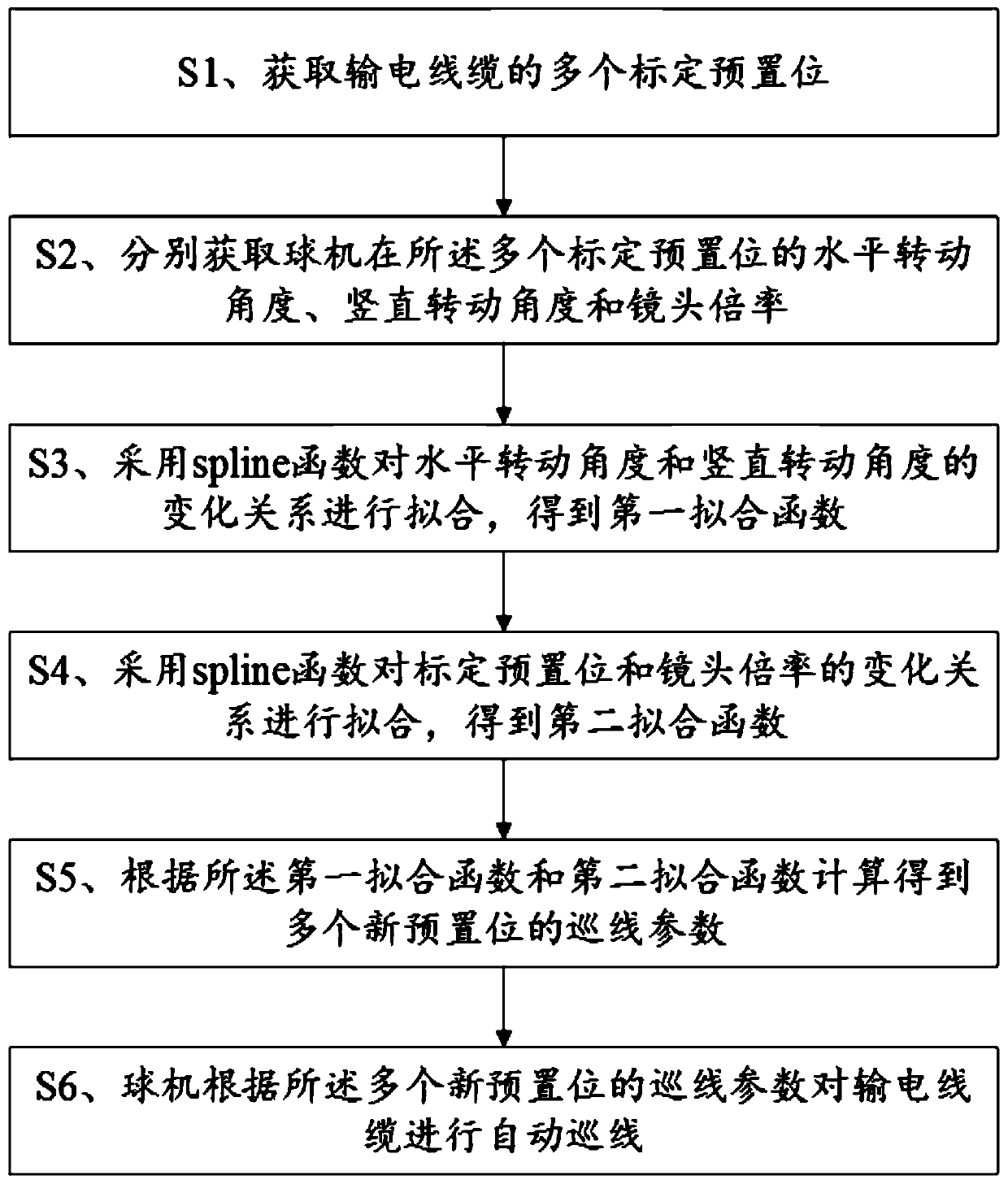

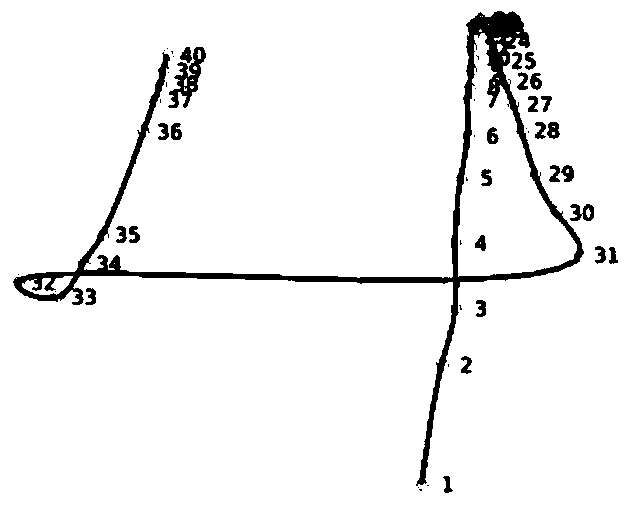

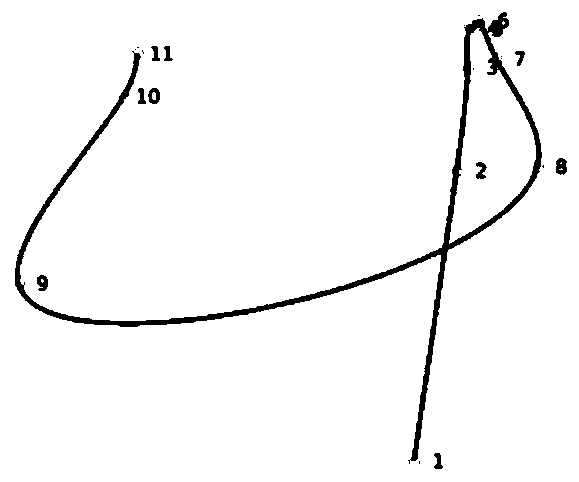

[0056] Please refer to Figure 1 to Figure 5 , Embodiment 1 of the present invention is a video line inspection method for power transmission cables, such as figure 1 shown, including the following steps:

[0057] S1. Obtain multiple calibration preset positions of the power transmission cable.

[0058] The calibration preset positions may include the starting point, end point and inflection point of the power transmission cable, etc., and the number of calibration preset positions can be selected according to needs.

[0059] S2. Respectively acquire the horizontal rotation angle, the vertical rotation angle and the lens magnification of the ball camera at the multiple calibration preset positions.

[0060] The horizontal rotation angle is Pan in PTZ, the vertical rotation angle is Tilt in PTZ, and the lens magnification is Zoom in PTZ.

[0061] S3. Using the spline function to fit the variation relationship between the horizontal rotation angle and the vertical rotation an...

Embodiment 2

[0070] Please refer to Image 6 , the second embodiment of the present invention is:

[0071] A transmission cable video line inspection terminal 100, corresponding to the method in Embodiment 1, including a memory 1, a processor 2, and a computer program stored in the memory 1 and operable on the processor 2, the processing Implement the following steps when the device 2 executes the computer program:

[0072] Obtain multiple calibration preset positions of the transmission cable;

[0073] Respectively acquire the horizontal rotation angle, vertical rotation angle and lens magnification of the dome camera at the multiple calibration preset positions;

[0074] Using the spline function to fit the relationship between the horizontal rotation angle and the vertical rotation angle to obtain a first fitting function;

[0075] The spline function is used to fit the change relationship between the calibration preset position and the lens magnification, and a second fitting functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com