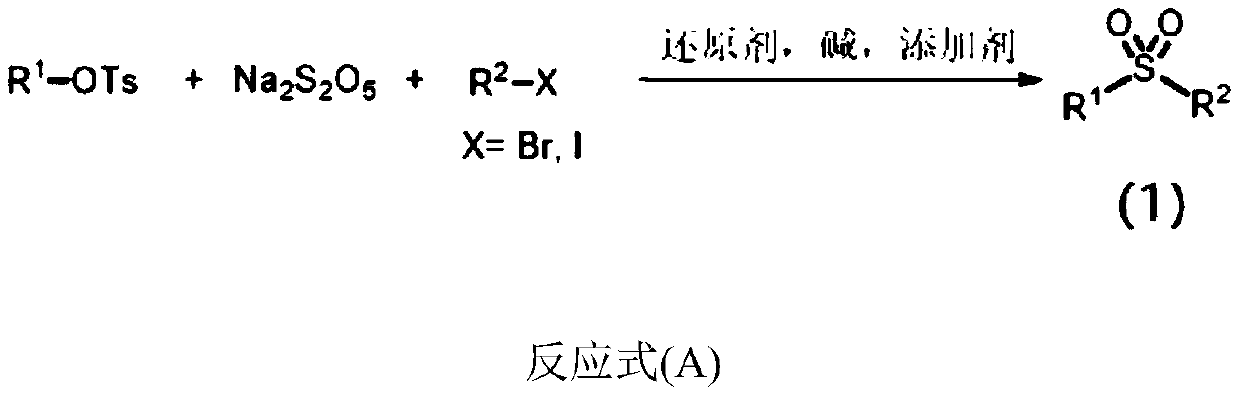

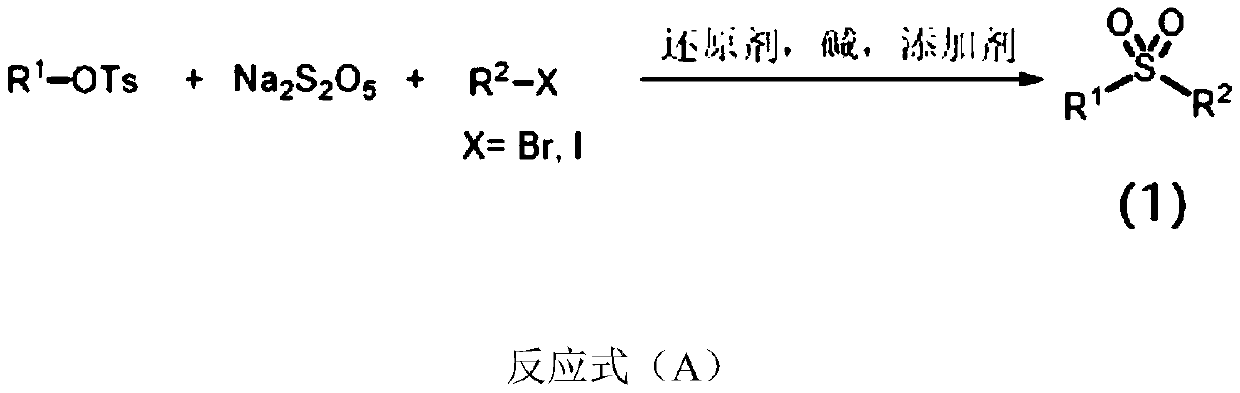

Alkyl alkyl sulfone compound as well as synthesis method and application thereof

A technology for the synthesis of alkyl alkyl sulfones, which is applied to the preparation of steroids, chemical instruments and methods, and organic compounds, and can solve the problems of poor substrate compatibility and heavy odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of compound 3a:

[0033]

[0034] Under nitrogen protection, p-methylsulfonate compound 1a (0.2mmol), sodium metabisulfite (0.4mmol, 2.0equiv.), potassium formate (0.5mmol, 2.5equiv.), cesium carbonate (0.4mmol, 2.0equiv. ), tetrabutylammonium bromide (0.3mmol, 1.5equiv.), join in the reaction tube that is placed with magneton, add iodide n-butane (0.5mmol, 2.5equiv.), DMSO ( 2.0mL) the reaction system was heated to 100°C and reacted for 10 hours. After the p-toluenesulfonate alkyl ester was completely converted by pointing plate detection, the reaction system was cooled to room temperature, diluted with water and added ethyl acetate (10mL*3) Extracted, dried over anhydrous sodium sulfate, filtered, concentrated, and separated by column chromatography to obtain the purified target product 3a (77%) (PE / EA=10:1to 5:1, Rf=1 / 2). 1 H NMR (400MHz, CDCl 3 )δ7.09(d, J=8.8Hz, 2H), 6.84(d, J=8.4Hz, 2H), 3.79(s, 3H), 2.91(t, J=8.0Hz, 2H), 2.72(t, J=7.6Hz, 2H), 2.17...

Embodiment 2

[0036] Synthesis of compound 3b:

[0037]

[0038] Under nitrogen protection, p-methylsulfonate compound 1b (0.2mmol), sodium metabisulfite (0.4mmol, 2.0equiv.), potassium formate (0.5mmol, 2.5equiv.), cesium carbonate (0.4mmol, 2.0equiv. ), tetrabutylammonium bromide (0.3mmol, 1.5equiv.), join in the reaction tube that is placed with magneton, add iodide n-butane (0.5mmol, 2.5equiv.), DMSO ( 2.0mL) the reaction system was heated to 100°C and reacted for 10 hours. After the p-toluenesulfonate alkyl ester was completely converted by pointing plate detection, the reaction system was cooled to room temperature, diluted with water and added ethyl acetate (10mL*3) Extracted, dried over anhydrous sodium sulfate, filtered, concentrated, and separated by column chromatography to obtain the purified target product 3b (81%) (PE / EA=10:1to 5:1). 1 H NMR (400MHz, CDCl 3 )δ7.25-7.21(m,2H),7.19-7.08(m,3H),2.87-2.83(m,4H),2.71(t,J=7.4Hz,2H),2.14-2.06(m,2H) ,1.73-1.65(m,2H),1.43-1.32(m,2...

Embodiment 3

[0040] Synthesis of compound 3c:

[0041]

[0042] Under nitrogen protection, p-methylsulfonate compound 1c (0.2mmol), sodium metabisulfite (0.4mmol, 2.0equiv.), potassium formate (0.5mmol, 2.5equiv.), cesium carbonate (0.4mmol, 2.0equiv. ), tetrabutylammonium bromide (0.3mmol, 1.5equiv.), join in the reaction tube that is placed with magneton, add iodide n-butane (0.5mmol, 2.5equiv.), DMSO ( 2.0mL) the reaction system was heated to 100°C and reacted for 10 hours. After the p-toluenesulfonate alkyl ester was completely converted by pointing plate detection, the reaction system was cooled to room temperature, diluted with water and added ethyl acetate (10mL*3) Extracted, dried over anhydrous sodium sulfate, filtered, concentrated, and separated by column chromatography to obtain the purified target product 3c (78%) (PE / EA=10:1to 5:1, Rf=1 / 2). 1 H NMR (400MHz, CDCl 3 )δ7.24-7.18(m,2H),7.10-7.01(m,2H),2.97-2.91(m,4H),2.82(t,J=7.3Hz,2H),2.21-2.13(m,2H) ,1.82-1.74(m,2H),1.50-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com