A kind of sputtering method of semiconductor chip

A semiconductor and chip technology, which is applied in the field of sputtering of semiconductor chips, can solve problems such as troublesome processing, irregular shapes, and complicated processes, and achieve the effects of reducing costs, conveniently separating and tearing glue, and conveniently clamping and taking out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

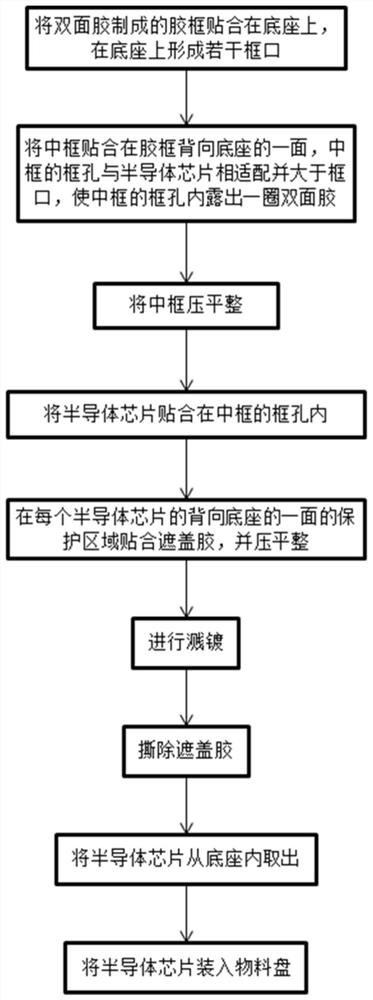

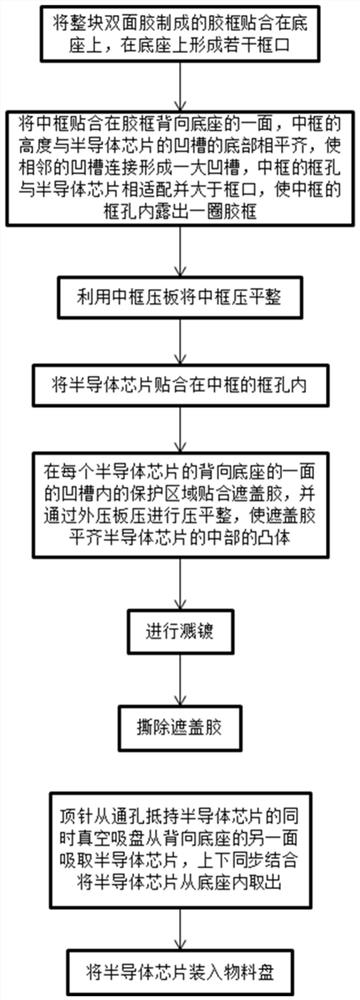

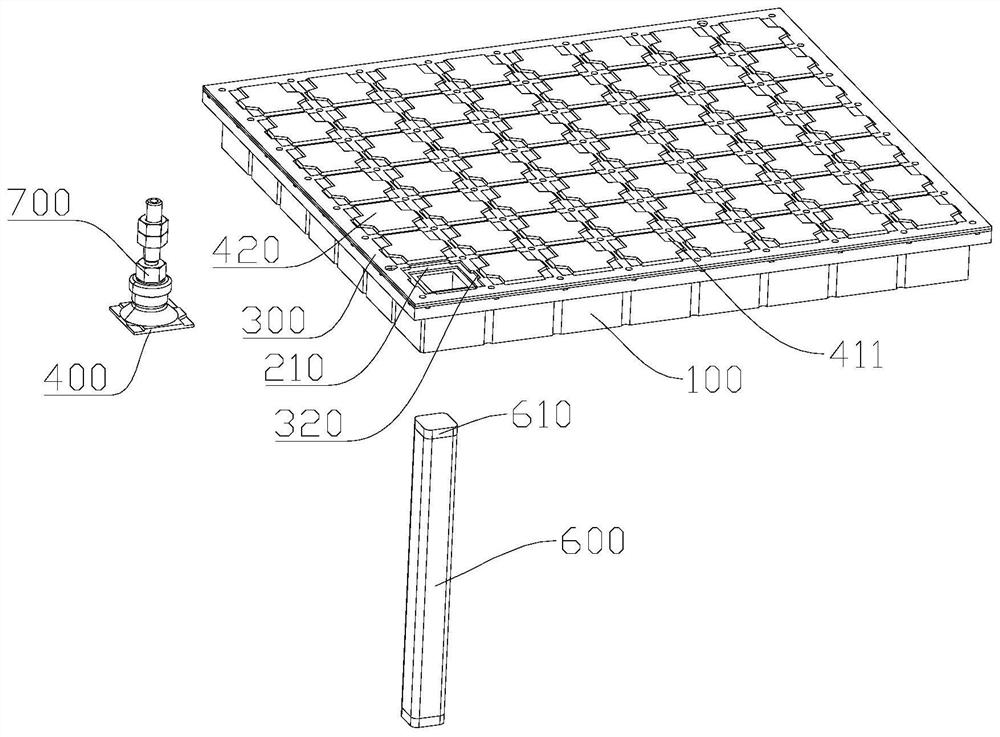

[0061] See Figure 1-Figure 8 ,

[0062] A. Lay the plastic frame 200 made of a whole piece of double-sided adhesive on the base 100, and form a number of frame openings 210 on the base 100; the base 100 is provided with a number of through holes 110 in an array, and the through holes 110 are criss-crossed A plurality of exhaust grooves 120 are provided, and a first air hole 130 is provided at the intersection of the exhaust grooves 120; Two air holes 220;

[0063] B. Attach the middle frame 300 on the side of the plastic frame 200 facing away from the base 100, the height of the middle frame 300 is flush with the bottom of the groove 410 of the semiconductor chip 400, so that the adjacent grooves 410 are connected to form a large concave Groove 411, the frame hole 310 of the middle frame 300 is adapted to the semiconductor chip 400 and is larger than the frame opening 210, so that a circle of plastic frame 200 is exposed in the frame hole 310 of the middle frame 300; the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com