Calculation method of antegrade index of blast furnace based on moving range

A technology of movement range and calculation method, which is applied in the field of blast furnace smelting, can solve problems such as the inability to effectively solve the problems of suspended material, collapsed material and furnace conditions, and the lack of guidance of blast furnace operators, so as to promote high-level stable production and data Reliable and avoid suspension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

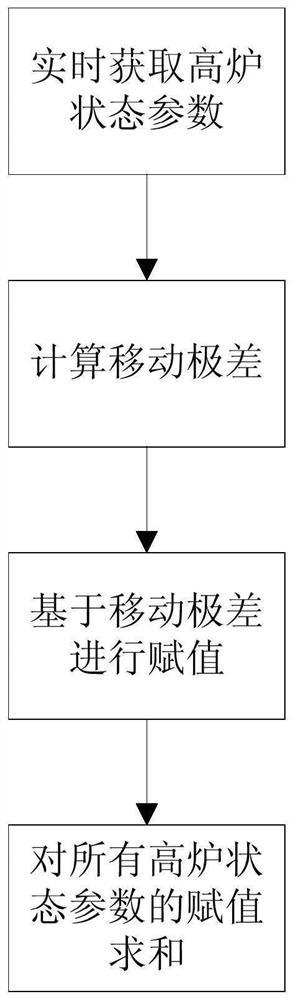

[0023] In order to calculate the antegrade index of the blast furnace more accurately, so as to improve the stability of the operation of the blast furnace, the present invention provides a method for calculating the antegrade index of the blast furnace based on the moving range, such as figure 1 shown, including the following steps:

[0024] During blast furnace production, according to the actual operation experience of smelting experts, select the blast furnace state parameters that affect the forward movement during the actual operation process, including blast furnace feeding speed, blast furnace wind pressure, blast furnace top pressure and gas percentage in the blast furnace ;

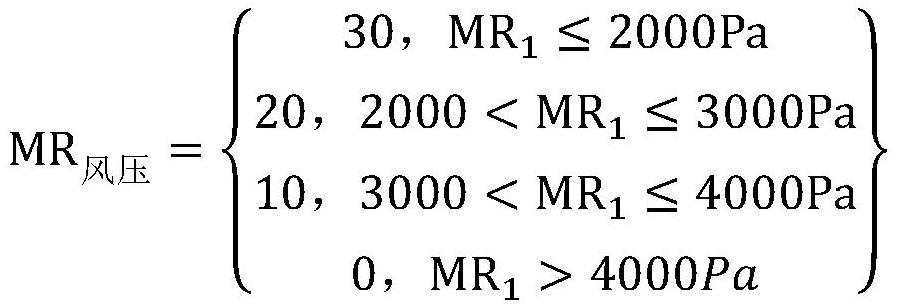

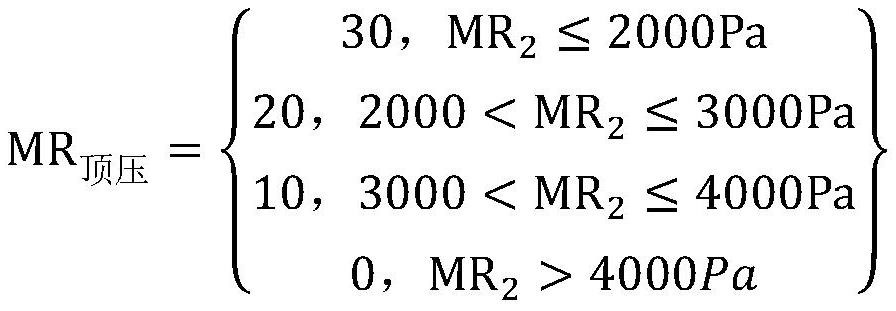

[0025] Assign values to various state parameters of the blast furnace, among which, wind pressure, top pressure, and gas percentage in the blast furnace are all assigned based on their respective moving ranges, which refer to the fluctuation of blast furnace state parameters within a period of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com