Critical current testing device and method for high-temperature superconducting tape in spiral winding state

A technology of high-temperature superconducting tape and critical current, applied to the critical current testing device in the spirally wound state of the high-temperature superconducting tape, the current testing device, and the field of critical current testing in the spirally wound state of the high-temperature superconducting tape, capable of Solve the problems of large errors and low efficiency of high-temperature superconducting strips, and achieve the effect of solving large errors, convenient test operation, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

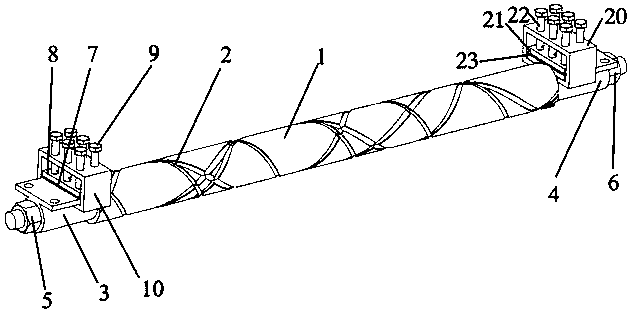

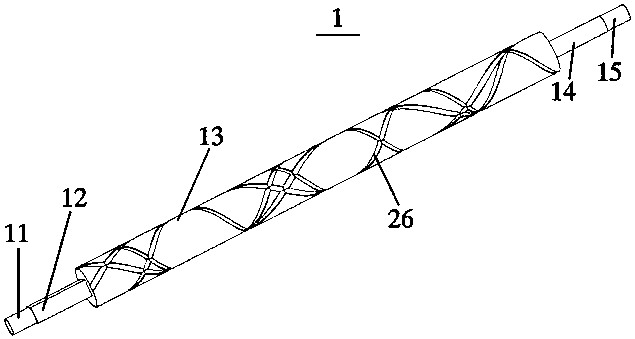

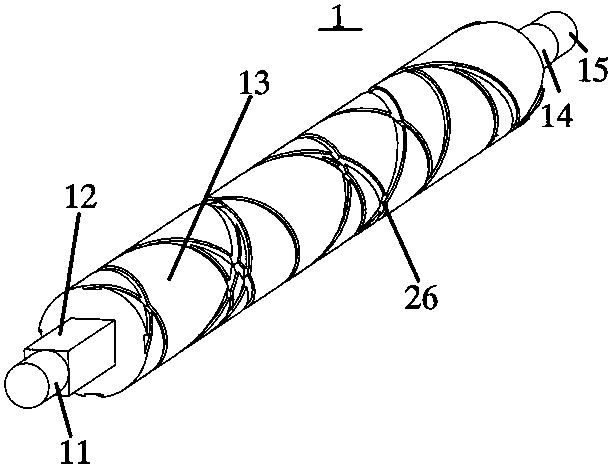

[0060] see Figure 1-7 , the present embodiment provides a critical current testing device suitable for the high-temperature superconducting tape in a spirally wound state, the device is used to test the critical current characteristics of the high-temperature superconducting tape 2 under the stress and strain of the spiral winding, for The safe application of high temperature superconducting tape 2 in superconducting power devices is of great significance. The critical current testing device includes a substrate 1, a fixed platform 1 3, a fixed platform 2 4 and a locking component, and may also include a plurality of high-temperature superconducting strips 2, a fixed component 1 and a fixed component 2. Wherein, the first fixed platform 3 and the second fixed platform 4 adopt the same fixed platform in this embodiment, but in other embodiments, these two platforms can be different. Similarly, the first fixed component and the second fixed component also use the same fixed co...

Embodiment 2

[0077] This embodiment provides a critical current testing device suitable for high-temperature superconducting strips in a helically wound state, which is similar to that of Example 1, except that the device in this embodiment does not include high-temperature superconducting strips 2, However, the high-temperature superconducting strip 2 exists only as a test object. For different high-temperature superconducting strips 2, the test device of this embodiment can test it, and because the test device is not provided with high-temperature superconducting strips 2, the manufacturing cost of the device can be reduced, and it is convenient to test various high-temperature superconducting strips. Superconducting strip 2 is tested to expand the scope of application of the test.

Embodiment 3

[0079] This embodiment provides a critical current testing system, which includes the critical current testing device in Embodiment 1 or 2, which is suitable for the high-temperature superconducting strip in a spirally wound state, and also includes a current measuring device and a current generating device. The current generating device is used to generate current. The device provides positive and negative terminals, and the positive and negative terminals are connected to the fixed platform 1 3 and the fixed platform 2 4 through cables, and output the test current to both ends of the high temperature superconducting strip 2, Thereby various critical currents can be tested. The current measuring device can measure the magnitude of the current, which is convenient for the test personnel to check the magnitude of the current of the high-temperature superconducting strip 2 in time, and is convenient for recording and counting the critical current data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com