A cleaning and screening method and equipment for recycling NdFeB waste

A technology of waste recycling and NdFeB, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of insufficient NdFeB recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

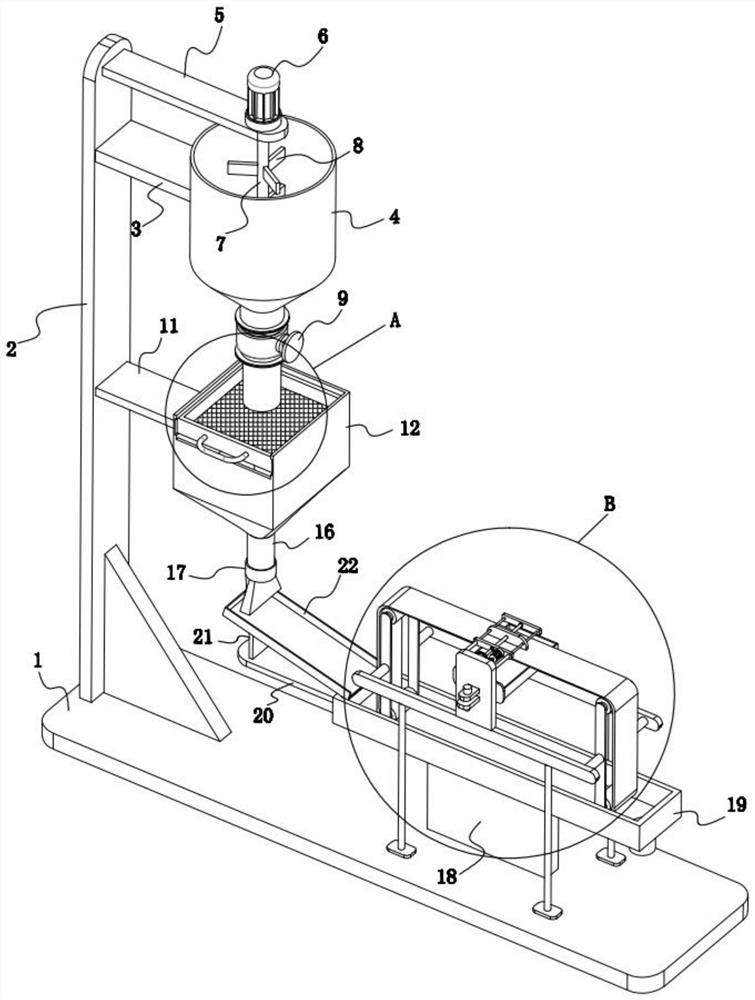

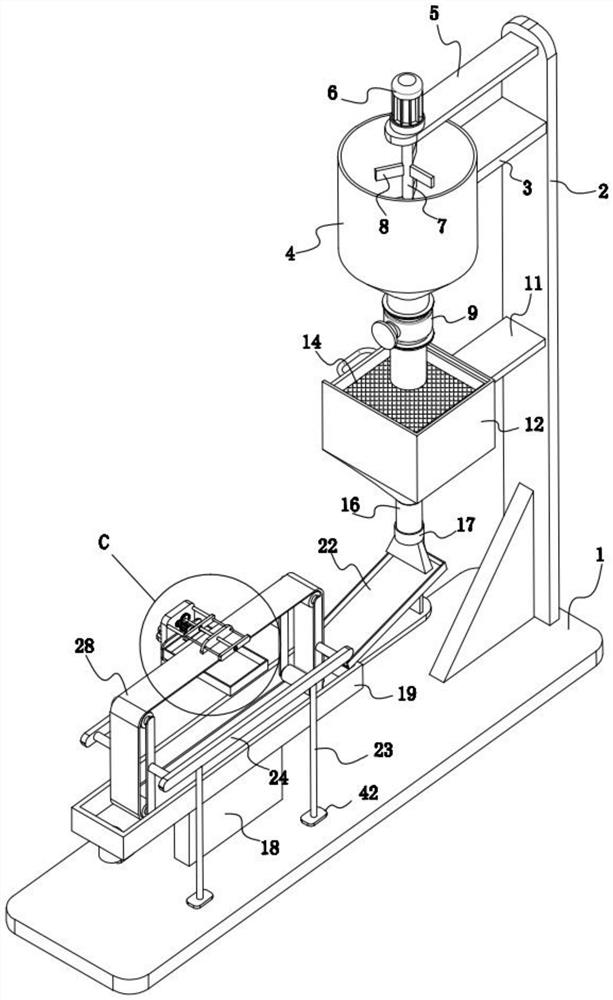

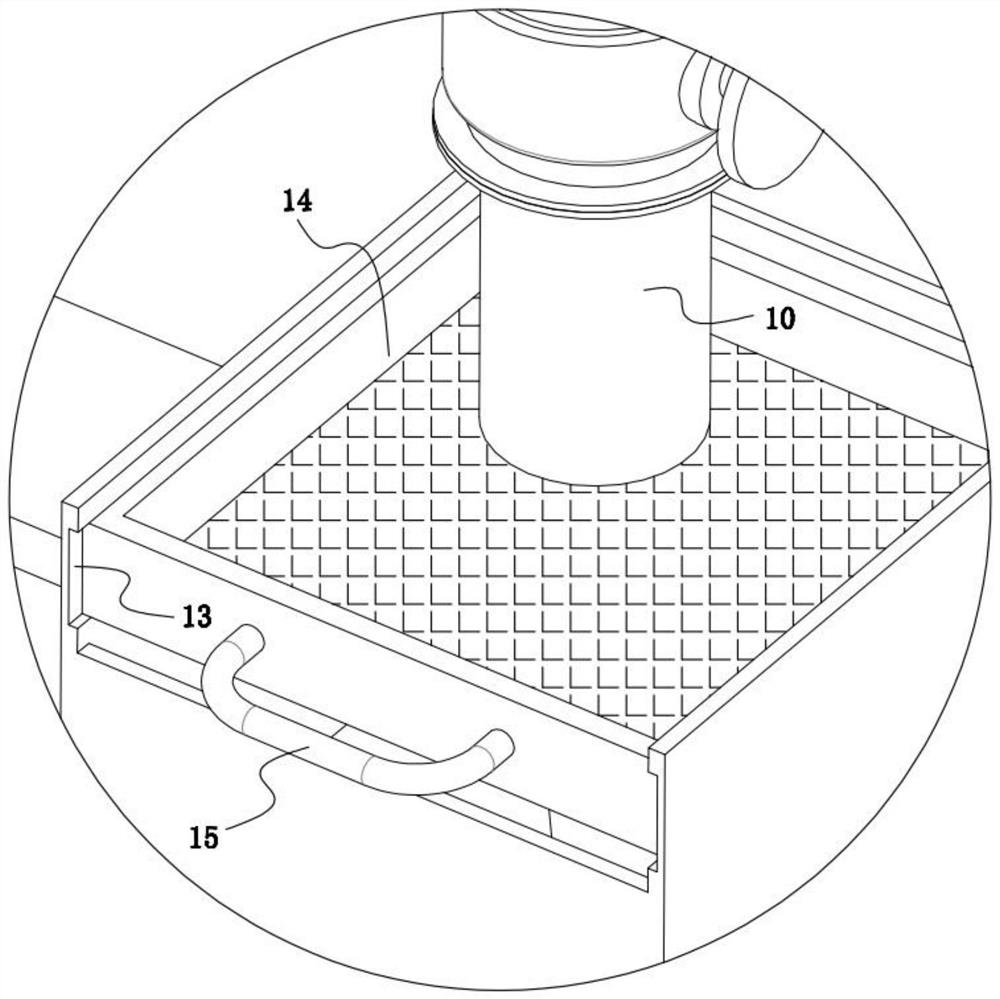

Embodiment 1

[0031] refer to Figure 1-7 , a cleaning and screening equipment for NdFeB waste recycling, comprising a bottom plate 1, a side plate 2 is fixedly installed on one side of the upper surface of the bottom plate 1, and a first fixed plate 3 is fixedly installed on the inner surface of the upper part of the side plate 2, and the first fixed plate 3 is fixedly installed with a mixing bucket 4, and the side plate 2 above the first fixing plate 3 is fixedly provided with a second fixing plate 5, and a motor 6 corresponding to the mixing bucket 4 is fixedly installed on the second fixing plate 5, and the motor 6 After the output shaft passes through the second fixed plate 5, it is fixedly connected with the stirring shaft 7, and the stirring shaft 7 extends downwards into the mixing bucket 4, and the surface of the stirring shaft 7 is fixed with several groups of blades 8 along the length direction, and the mixing bucket 4. A first discharge pipe 10 is fixedly connected to the bottom...

Embodiment 2

[0044] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the drainage mechanism includes a horizontal plate 20, a vertical plate 21, and an inclined plate 22, and a screen corresponding to the screening box 19 is provided directly below the second discharge pipe 16. The inclined plate 22, the lower surface of the inclined plate 22 is fixedly provided with a vertical plate 21, and the bottom end of the vertical plate 21 is fixedly equipped with a horizontal plate 20, and the horizontal plate 20 is fixedly installed on the screening box 19. The bottom end of the second discharge pipe 16 is covered with a nozzle 17 .

[0045] By setting the drainage mechanism, the dirty water flowing out of the screening bucket 12 can be more evenly introduced into the screening box 19, so that the contact between the conveyor belt 28 and the dirty water is more uniform and effective, and then the coating on the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com