A roadbed laying and leveling machine for highway construction

A technology of leveling machine and roadbed, applied in the direction of roads, roads, road repair, etc., can solve the problems of clay adhesion, abrupt concave holes, and redundant clay scattered, and achieve the effect of increasing cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

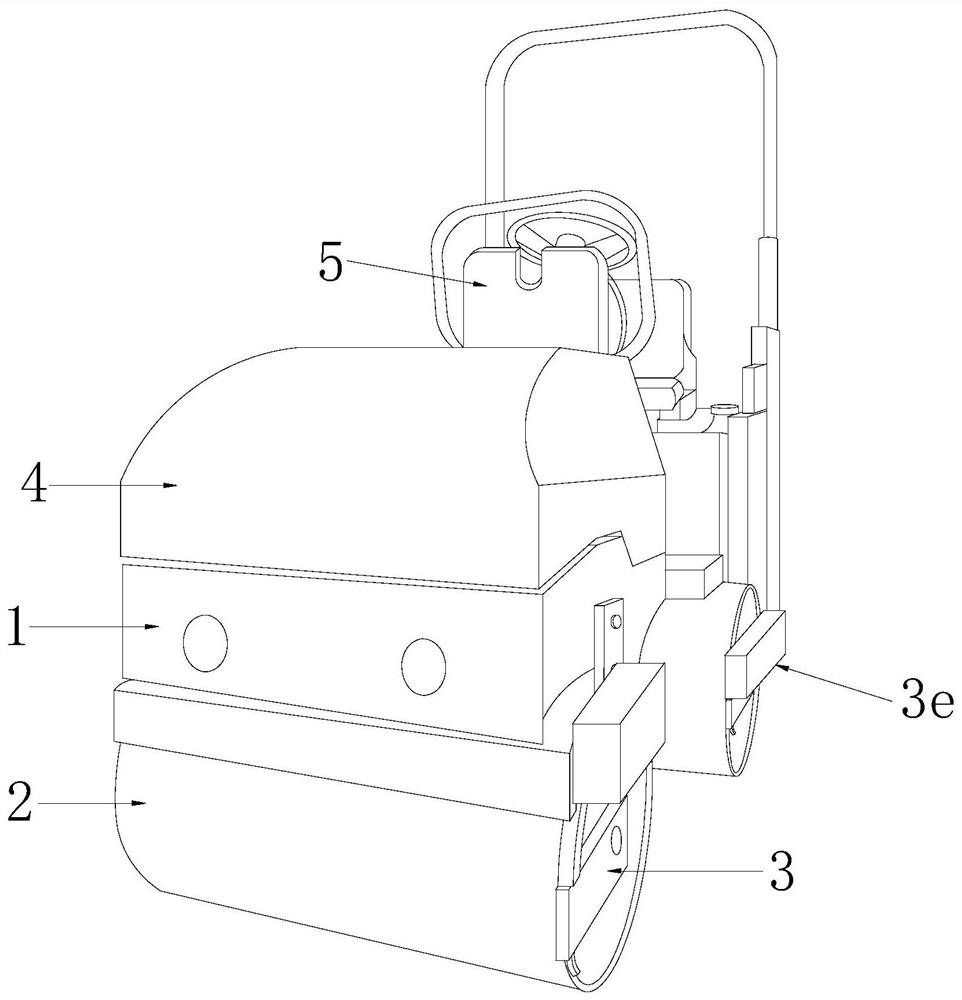

[0027] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of technical scheme of roadbed laying leveler for road construction:

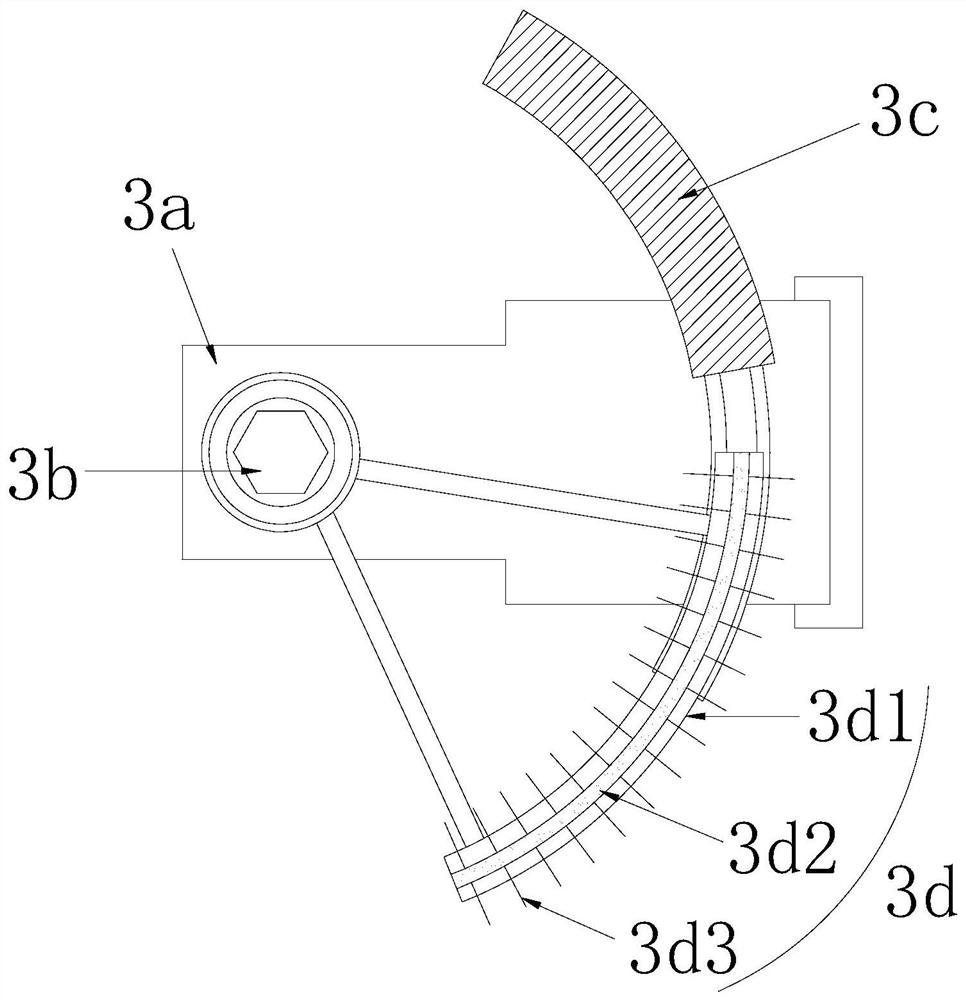

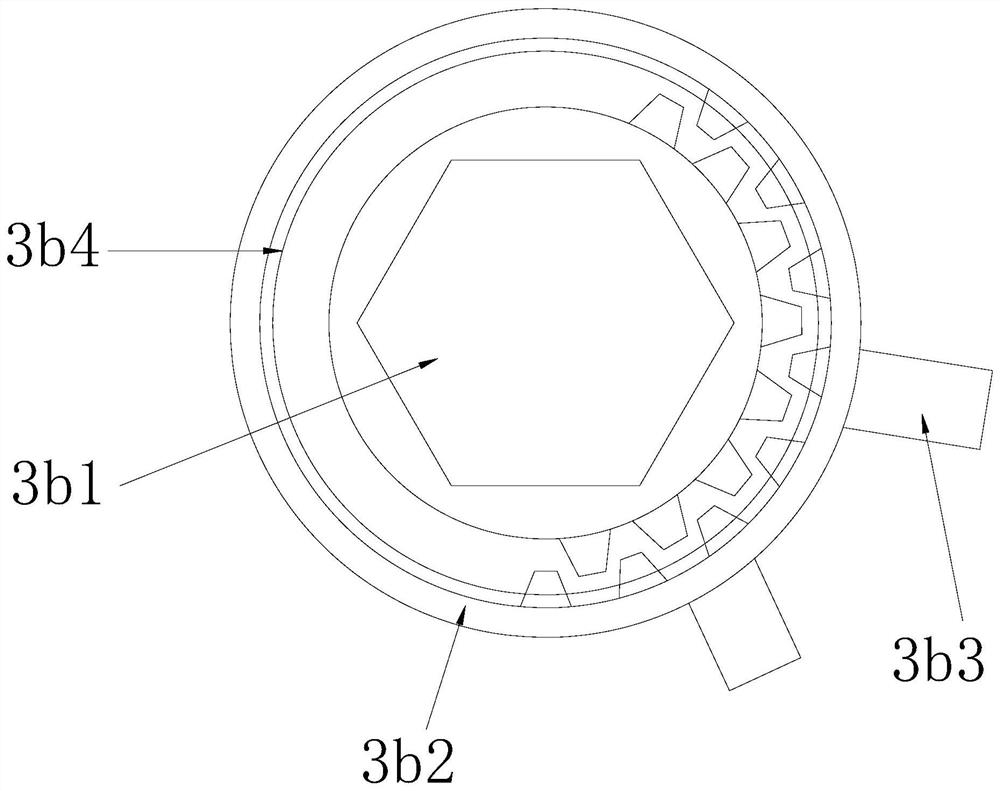

[0028] Such as Figure 1-Figure 2 As shown, a roadbed leveling machine for road construction, its structure includes a device body 1, a roller shaft 2, a stroker device 3, a dust cover 4, and a control room 5, and the roller shaft 2 is provided in total. There are two and are respectively installed on the lower surface of the equipment main body 1 and connected by electric welding. The edge stroke device 3 is arranged on the left and right sides of the roller shaft 2 and connected by electric welding. The dustproof cover 4 is arranged on the equipment main body 1 The upper surface is connected by electric welding. The control room 5 is arranged on the front surface of the equipment main body 1 and connected by electric welding. The edge stroke device 3 includes a baffle plate 3a, a limit structure 3b, a light button mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com