Novel snap spring anti-loosening connector

An anti-loosening and connector technology, applied in the direction of connection, parts and electrical components of the connection device, etc., can solve the problems of low reliability, inconvenient installation and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

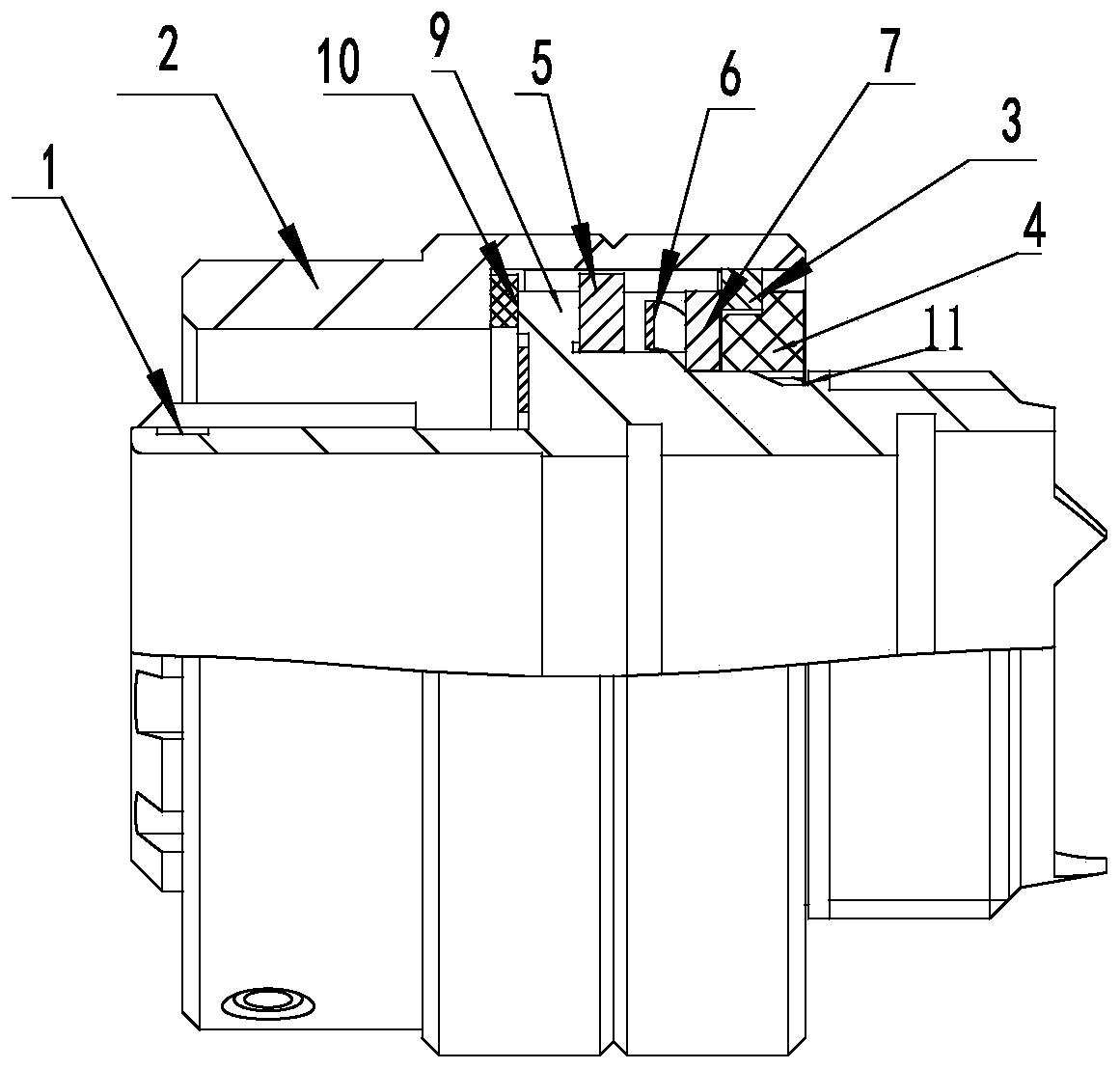

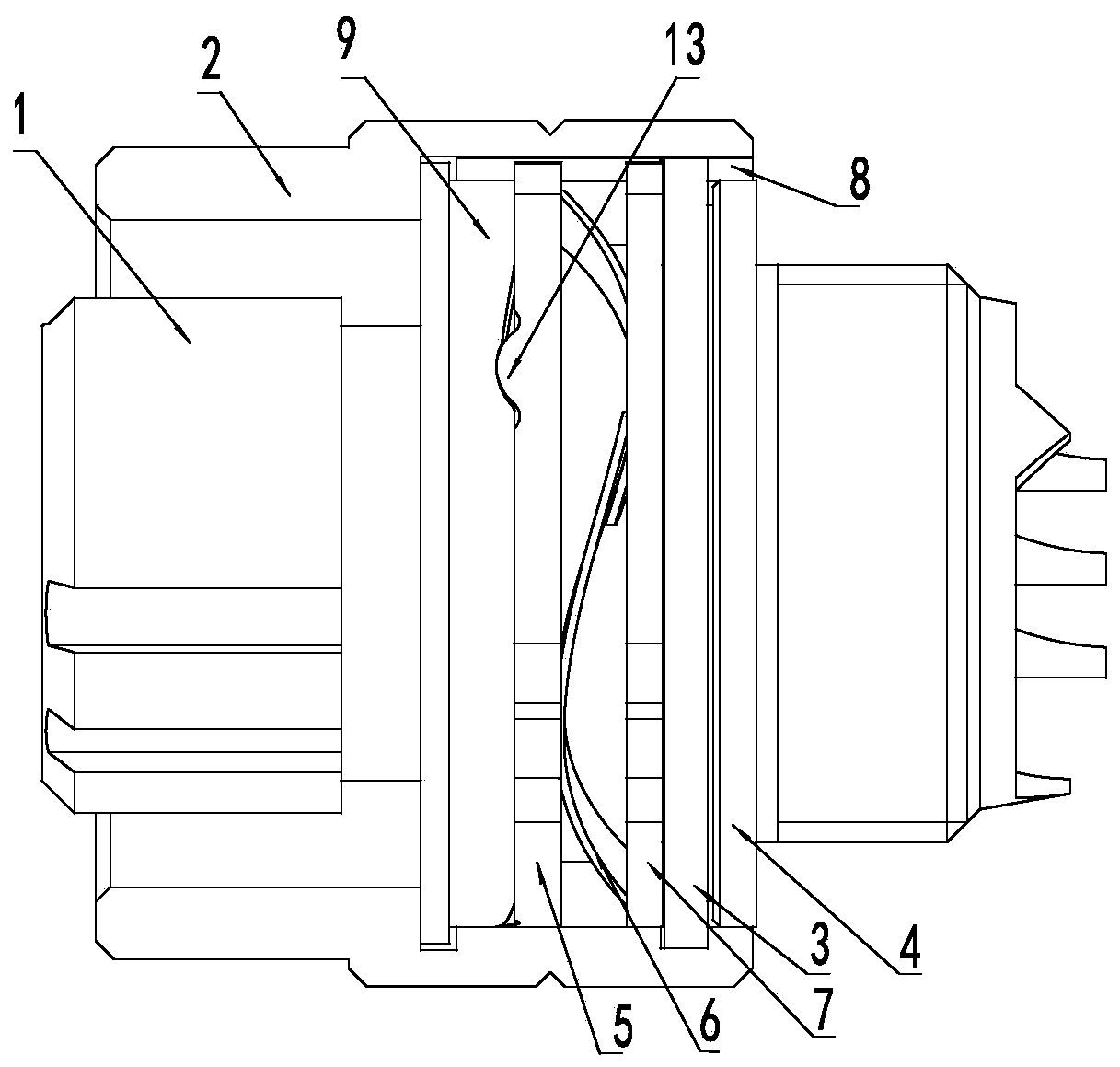

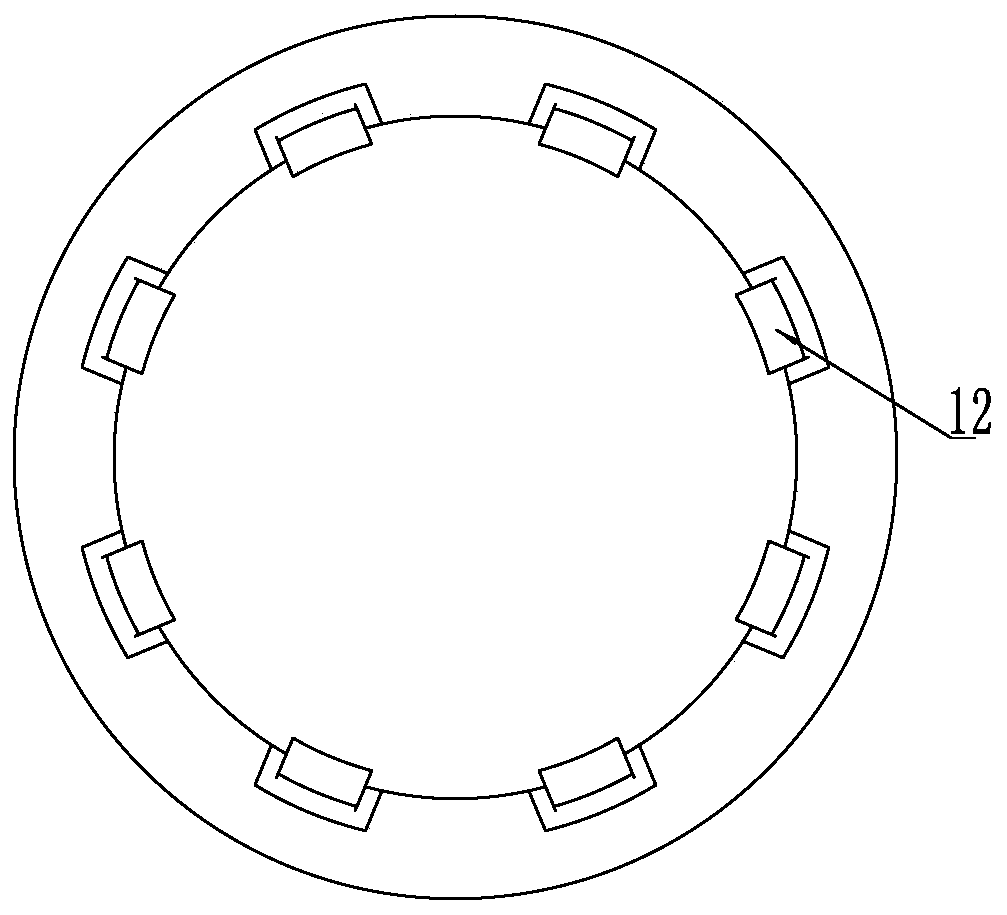

[0037] see Figure 1-6 , which is a structural schematic diagram of a new spring anti-loosening connector of the present invention. The connector includes an outer shell 1 and a connecting nut 2 that is rotatably assembled outside the outer shell. The front end of the collar 4 on the outer casing 1 and axially limited by the outer casing 1 extends into the inner ring of the jumper 3 to prevent the jumper from shrinking inwardly and disengaging from the connecting nut.

[0038] An anti-loosening component is also provided between the outer shell and the connecting nut, and the anti-loosening component is axially limited by the snap spring 3 . Preferably, the outer periphery of the front end of the collar 4 is in contact with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com