Intelligent controller for garbage can and garbage can supervision system

A trash can and controller technology, applied in trash cans, garbage collection, household appliances, etc., can solve the problem of no very convenient method, and achieve the effect of reliable use and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

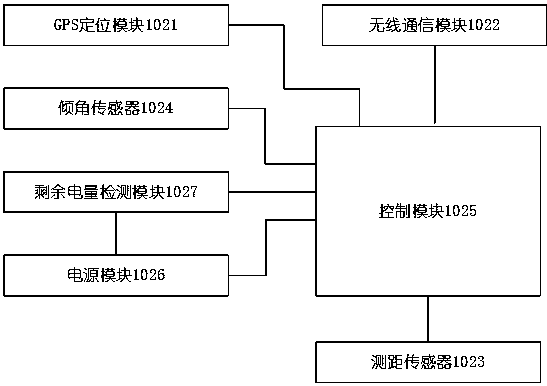

[0064] Figure 1-5 It is an embodiment of the garbage bin intelligent controller of the present invention.

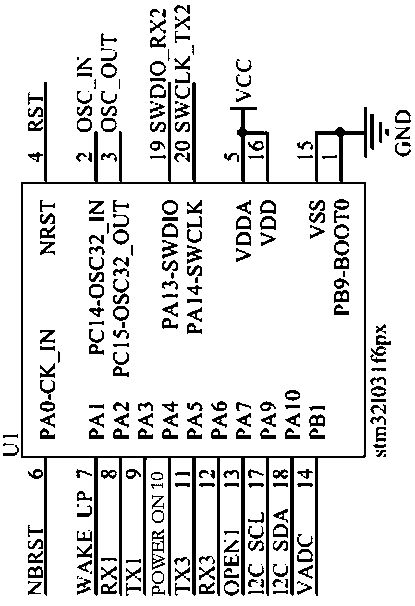

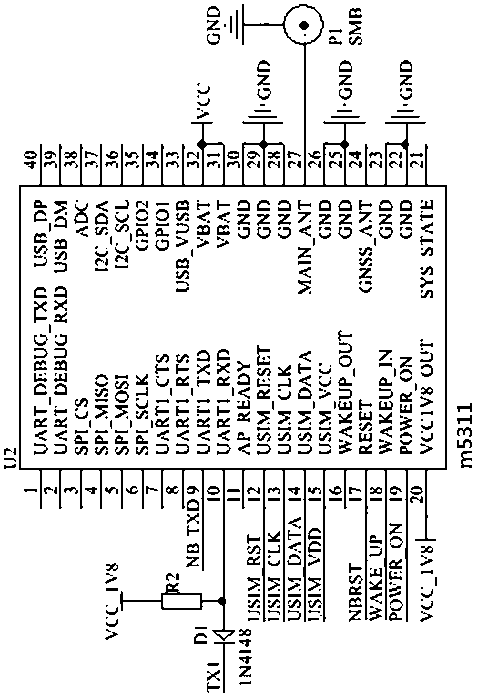

[0065] see Figure 1-5 , the dustbin intelligent controller described in this embodiment includes a housing 2, and includes a wireless communication module 1022 integrated in the housing 2, a control module 1025, and is used to provide the entire dustbin intelligent controller 102 The power supply module 1026 of the power supply, and the distance measuring sensor 1023 integrated on the casing 2 . The wireless communication module 1022 and the ranging sensor 1023 are both connected to the control module 1025 . Wherein, the control module 1025 communicates with the outside world through the wireless communication module 1022 . The control module 1025 can receive the installation mode of the dustbin intelligent controller set by the outside through the wireless communication module 1022 . The installation methods include top installation and side installation.

[0066...

Embodiment 2

[0081] Such as Figure 6 As shown, the present invention also provides a garbage can supervision system, the system 100 includes a garbage can management system 101 and a corresponding number of detection equipment 102, and each detection equipment 102 uses the garbage can intelligent controller described in the above embodiment ,in:

[0082] Each detection device 102 is connected to the trash can management system 101 through a wireless network;

[0083] The trash can management system 101 includes a device management unit, a user management unit, an early warning unit, a display unit and a data storage unit, wherein:

[0084] The device management unit is used to add and delete the bound detection device 102, to set the installation method of the added detection device 102, to create a group, to set the group of the added detection device 102 , used to set the working state of the added detection device 102, used to set the working time period of the set working state; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com