Automatic label welding method and device based on multiple steel bundles

An automatic welding and signage technology, applied in the field of image processing, can solve the problem that the system is difficult to identify the outline of each steel bundle and affects the selection accuracy of signage welding points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

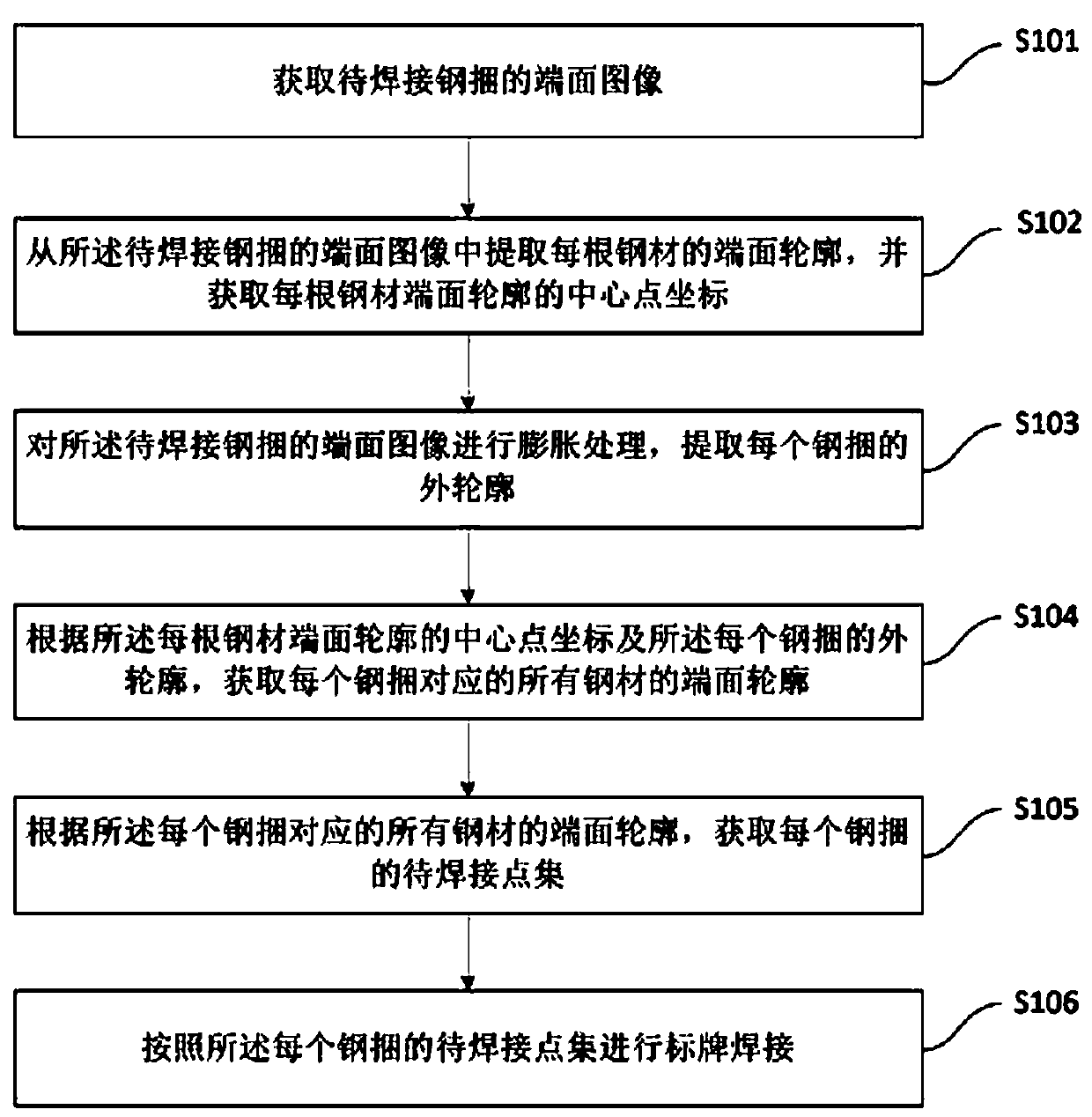

[0090] The first embodiment of the present application discloses an automatic welding label method based on multiple steel bundles, see figure 1 As shown in the schematic diagram of the workflow, the method includes:

[0091] Step S101 , acquiring an end face image of a steel bundle to be welded, where at least one steel bundle is included in the steel bundle to be welded.

[0092] The end face image of the steel bundle to be welded is collected by a binocular camera, the binocular camera includes a first camera and a second camera, and the collected end face image includes the first end face image collected by the first camera and the second camera Acquired second end face image.

[0093] Step S102, extracting the end surface profile of each steel material from the end surface image of the steel bundle to be welded, and obtaining the center point coordinates of the end surface profile of each steel material.

[0094] Based on the first end face image and the second end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com