Method for secondary selection of self-discharge battery

A battery and battery capacity technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve problems such as waste of production capacity, loss, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

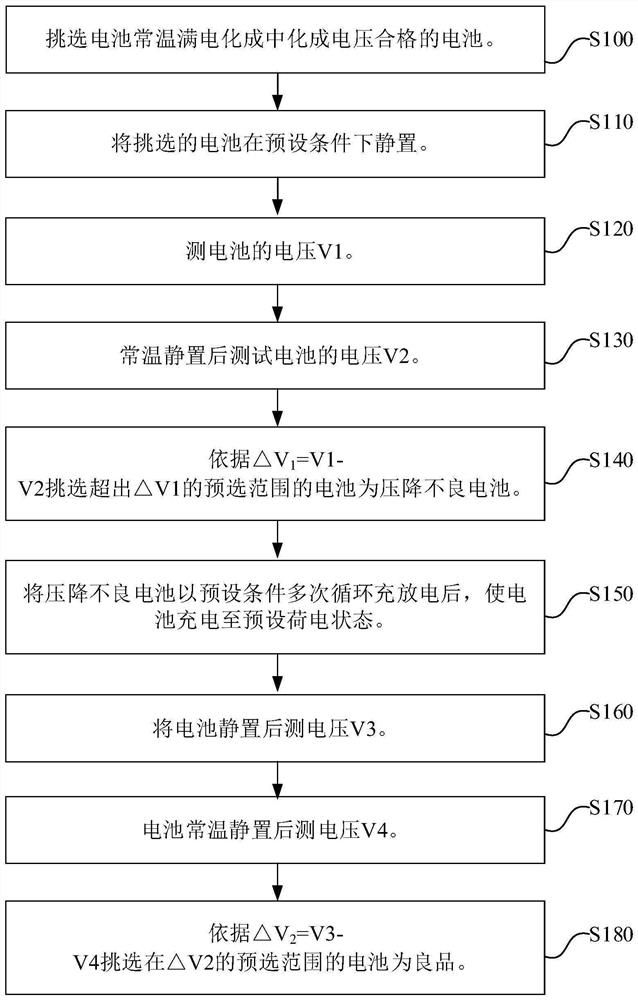

Image

Examples

Embodiment 1

[0051] Charge the battery with bad self-discharge settlement to 4.2V with 0.3C constant current and constant voltage, cut-off current 0.05C, then discharge at 0.5C constant current to 2.75V, cycle for 5 weeks, then charge at 0.5C for 60min, and let it stand for 24h The post-test voltage is V3. After the voltage test is completed, store at room temperature for 7 days and measure the voltage again to be V4, and then use △V 2 =V3-V4 to obtain the mean value and standard deviation for settlement. The comparison test was done at the same period, the process was consistent, and the batteries were selected according to the pressure drop gradient to be stored and disassembled respectively. The results are shown in Table 1.

[0052] Table 1 Pressure drop data results

[0053] battery number 1# 2# 3# 4# 5# 6# 7# 8# 9# 10# One-time selection voltage drop / mV 5.8 6.2 6.2 6.4 6.8 7.2 7.3 8.0 5.2 5.3 Secondary selection pressure drop / mV 4.0 4.8 6.2...

Embodiment 2

[0055] Charge the battery with bad self-discharge settlement to 4.2V with 0.5C constant current and constant voltage, cut-off current 0.05C, then discharge to 2.75V with 1C constant current, cycle for 3 weeks, then charge with 1C for 42min, and test after standing for 24h The voltage is V3. After the voltage test is completed, store at room temperature for 5 days and measure the voltage again to be V4, and then use △V 2 =V3-V4 to obtain the mean value and standard deviation for settlement. The comparison test was done at the same period, and the process was consistent. The batteries were selected according to the pressure drop gradient and stored and disassembled respectively. The results are shown in Table 2.

[0056] Table 2 Pressure drop data results

[0057] battery number 1# 2# 3# 4# 5# 6# 7# 8# 9# 10# One-time selection voltage drop / mV 6.2 6.5 6.9 7.3 7.6 8.0 8.3 8.8 4.8 5.0 Secondary selection pressure drop / mV 8.3 4.9 5.0 4.8...

Embodiment 3

[0059] Charge the battery with bad self-discharge settlement to 4.2V with 0.5C constant current and constant voltage, cut-off current 0.05C, then discharge to 2.75V with 1C constant current, cycle for 6 weeks, then charge at 0.8C for 45min, and let it stand for 24h The measured voltage is V3, and after the voltage test is completed, store at room temperature for 3 days and measure the voltage again as V4, and then use △V 2 =V3-V4 to obtain the mean value and standard deviation for settlement. The comparison test was done at the same period, and the process was consistent. The batteries were selected according to the pressure drop gradient and stored and disassembled respectively. The results are shown in Table 3.

[0060] Table 3 Pressure drop data results

[0061] battery number 1# 2# 3# 4# 5# 6# 7# 8# 9# 10# One-time selection voltage drop / mV 5.8 6.2 6.7 7.2 7.6 8.2 8.8 9.4 4.4 4.8 Secondary selection pressure drop / mV 5.1 4.9 8.7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com