A trailer coupler connection structure

A technology for connecting structures and trailers, used in traction connectors, vehicle parts, transportation and packaging, etc., can solve the problems of strong instantaneous local stress, fatigue damage, and the safety of trailers affecting the service life of the device. Stress, the effect of avoiding collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

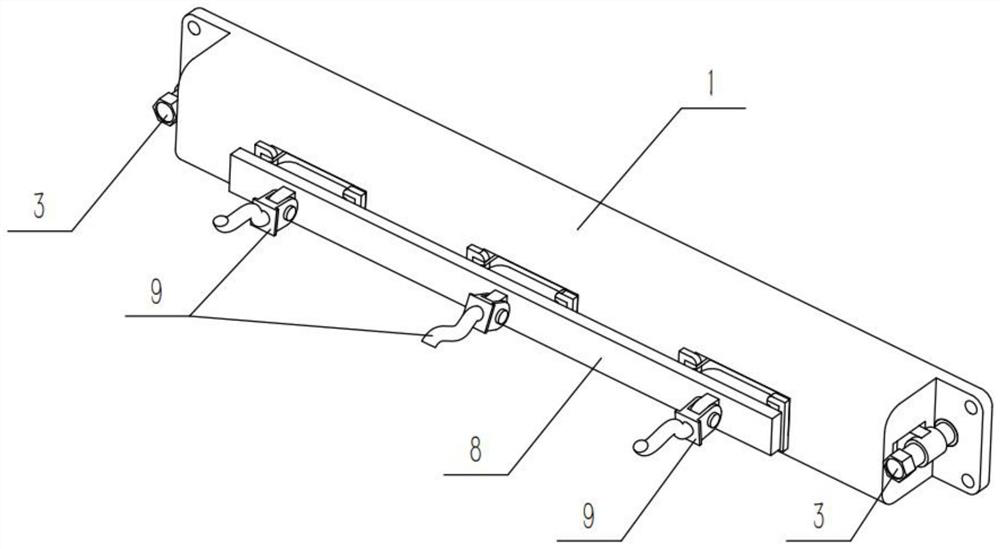

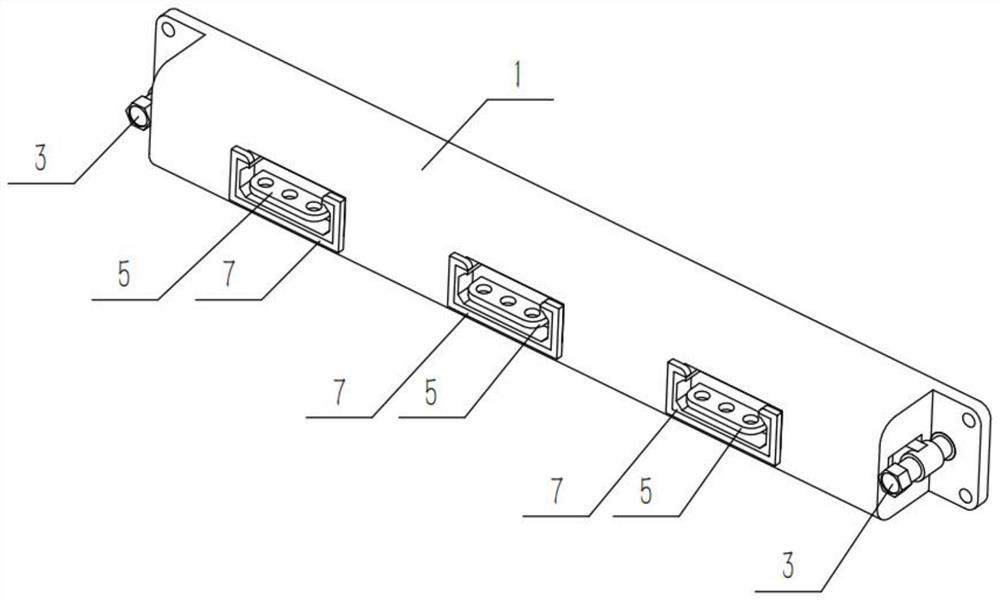

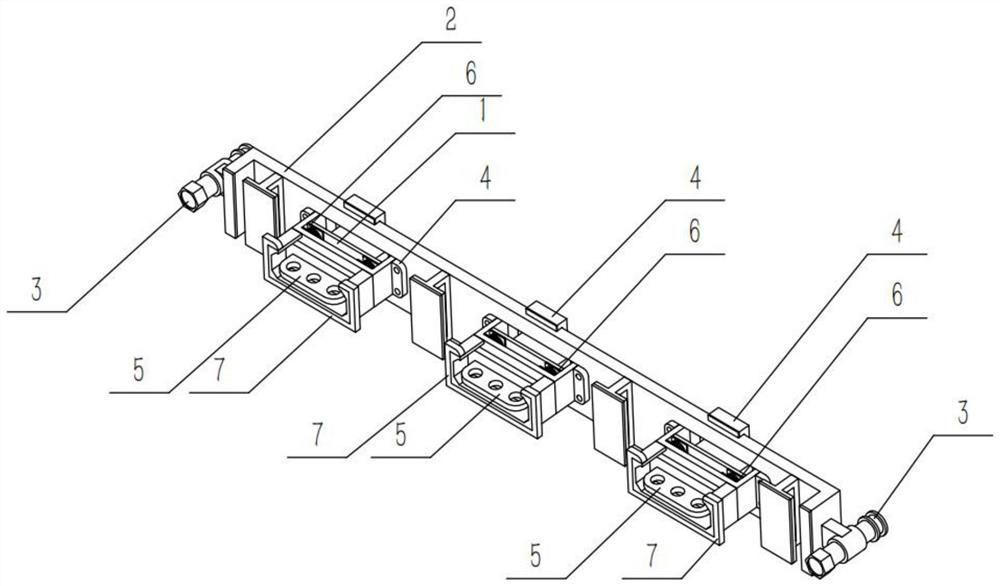

[0035] Bonded below Figure 1-11 In the present embodiment, a trailer hook connection structure includes a collision beam 1, a main slide 2, and a regulating column 3, the collision beam 1 mounted in front of the vehicle, the main skateboard 2 slides in the collision Inside the beam 1, the modulation post 3 is provided with two, and the rear end of the two adjustment columns 3 is rotatably connected to both sides of the collision beam 1, and the main body is connected to both sides of the main slide 2, respectively. The trailer hook is connected to the structure including the follow-up slide 4, the connecting slide 5, the buffer structure 6, the running frame 7, the connecting plate 8, and the connecting assembly 9, which are set to have multiple, multiple plus slippery The frame 4 is evenly provided in the main skate plate 2, and each followed by the slide frame 4 is slid to be connected to the connection slide 5, the connection slide 5 and the corresponding follow-up frame 4 fixe...

specific Embodiment approach 2

[0046] Bonded below Figure 1-11 In the present embodiment, the present embodiment will further explain the embodiment, and the connecting assembly 9 includes a hinged end 9-1 and a towline 9-2, the hinged end 9-1 hinges in the respective articulated portion 8-1. The front portion of the hinged end 9-1 is fixedly connected to a towline 9-2, and the tula 9-2 is connected to the trailer.

[0047] A trailer hook connection structure of the present invention is:

[0048] The anti-collision beam 1 is mounted to the front of the vehicle to be towed, and the two staff can use the wrench to rotate the nut head 3-2 on both sides simultaneously, and the two adjustment columns 3 respectively passed the thread transmission. Connect, so when the nut head 3-2 drives the adjustment column 3 to rotate, the transmission member 2-1 will slide forward or before, the device is in an attachment when the initial state is at an attachment. figure 2 When the position is used, the adjustment column 3 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com