door assembly

An assembly and door technology, applied in the field of car door assembly, can solve the problems of high cost, investment in laser production lines and equipment, etc., and achieve the effect of smooth waistline water cutting, increasing selection and different needs, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

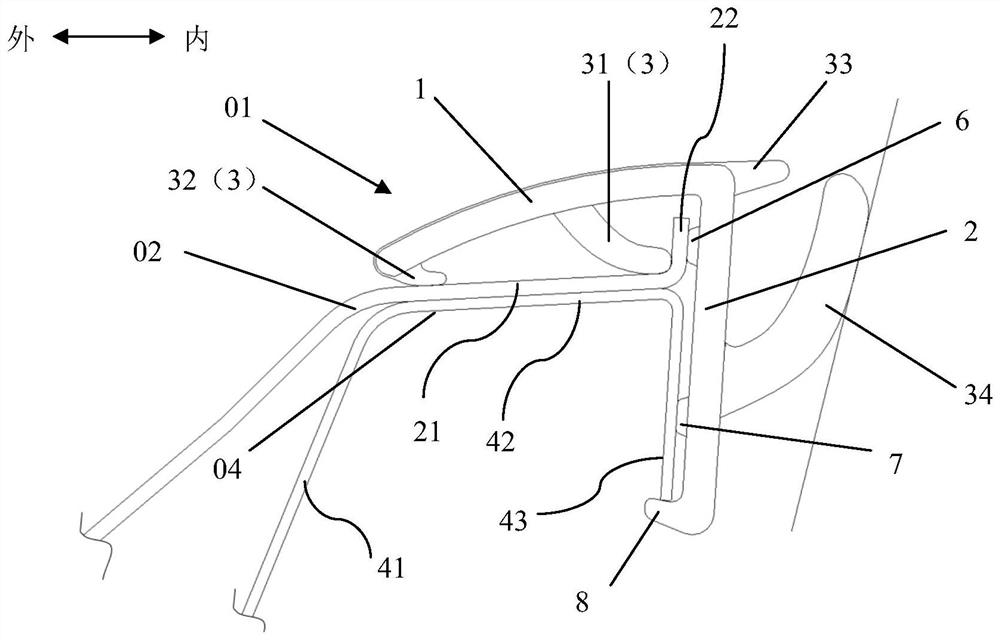

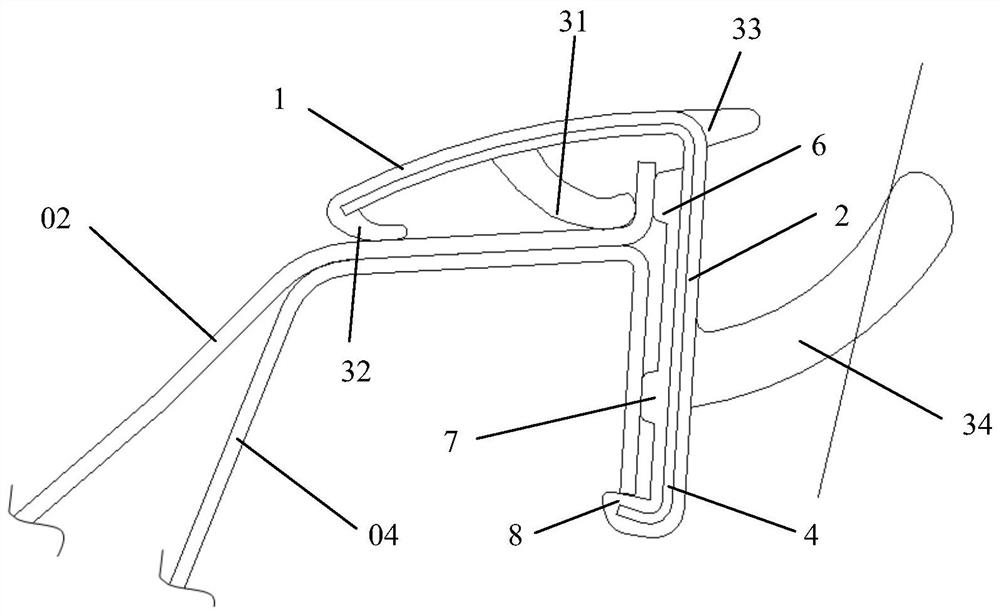

[0056] see Figure 1-8 Shown is the schematic diagram of the flat water cutting in the first embodiment.

[0057] Flat water cut 01, including decorative top cover 1, skeleton 2 and lip 3, decorative top cover 1 is used to cover the outer sheet metal 02, skeleton 2 extends from decorative top cover 1, lip 3 extends from decorative top cover 1 and / or The skeleton 2 extends out, the decorative top cover 1 gradually inclines upward from the outside to the inside, and the lip 3 includes a first lip 31, and the first lip 31 starts from the middle section of the bottom surface of the decorative top cover 1 and gradually extends downward and inward. A lip 31 is used to closely match and support the corner of the outer sheet metal 02.

[0058] The flat water cut 01 is a strip-shaped structure, arranged along the front and rear direction of the vehicle body, and is used to connect with the outer sheet metal 02 and the reinforcement plate 04 of the car door to form the outer waistline ...

Embodiment 2

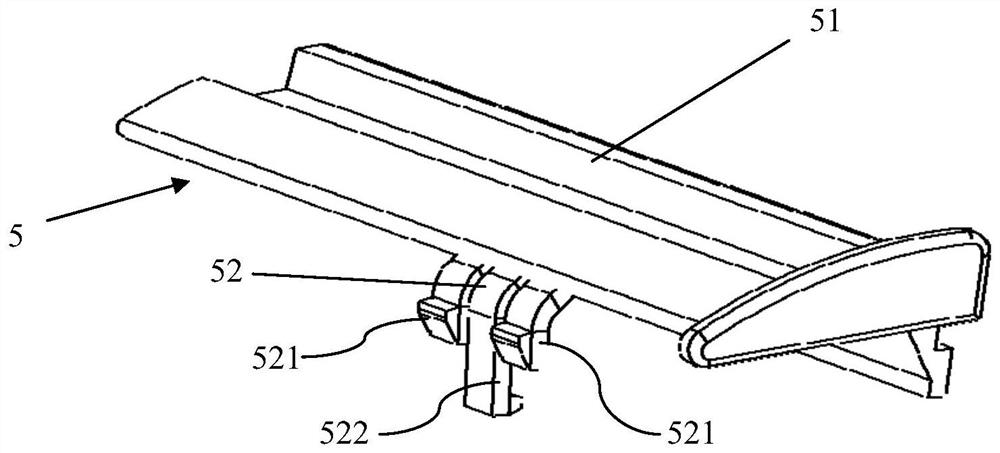

[0085] see Figure 9-15 Shown is the schematic diagram of the door assembly in the second embodiment.

[0086] Such as Figure 10 As shown, the door assembly includes the outer sheet metal 02 and the inner sheet metal 03, and also includes the flat horizontal cut 01 in the first embodiment and its modified example.

[0087] The flat water cut 01 is installed at the waistline position of the outer sheet metal 02 and the reinforcing plate 04, and extends along the front-rear direction of the vehicle body.

[0088] Since the first lip 31 of the flat water cut 01 is obliquely pressed downward against the corner of the outer sheet metal 02, the outer sheet metal 02 exerts a downward and inner pressure, and the force on the outer sheet metal 02 is greater, and the pressing effect is better it is good.

[0089] Further, as figure 1 with Figure 13 As shown, the upper side of the outer sheet metal 02 is provided with a first flange 21 and a second flange 22, the first flange 21 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com