A new energy vehicle charging pile

A technology of new energy vehicles and charging piles, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve problems such as troublesome maintenance, single connection between cables and interfaces, and insensitive charging interfaces, etc., to prolong the service life , Guarantee normal power supply and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

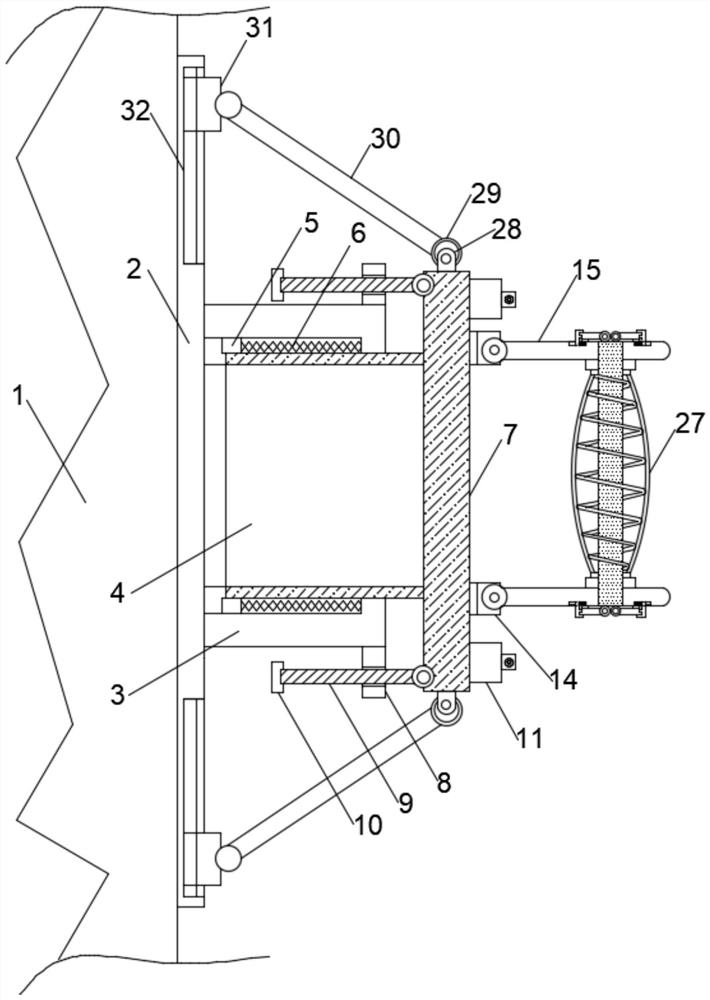

[0026] Including the charging pile body 1, one side of the charging pile body 1 is provided with an interface, one side of the interface is provided with a substrate 2, the substrate 2 is fixed on the charging pile body 1, and the middle part of the substrate 2 is provided with an opening, and one of the openings is There is a telescopic adjustment mechanism on one side, and a protective mechanism on one side of the telescopic adjustment mechanism;

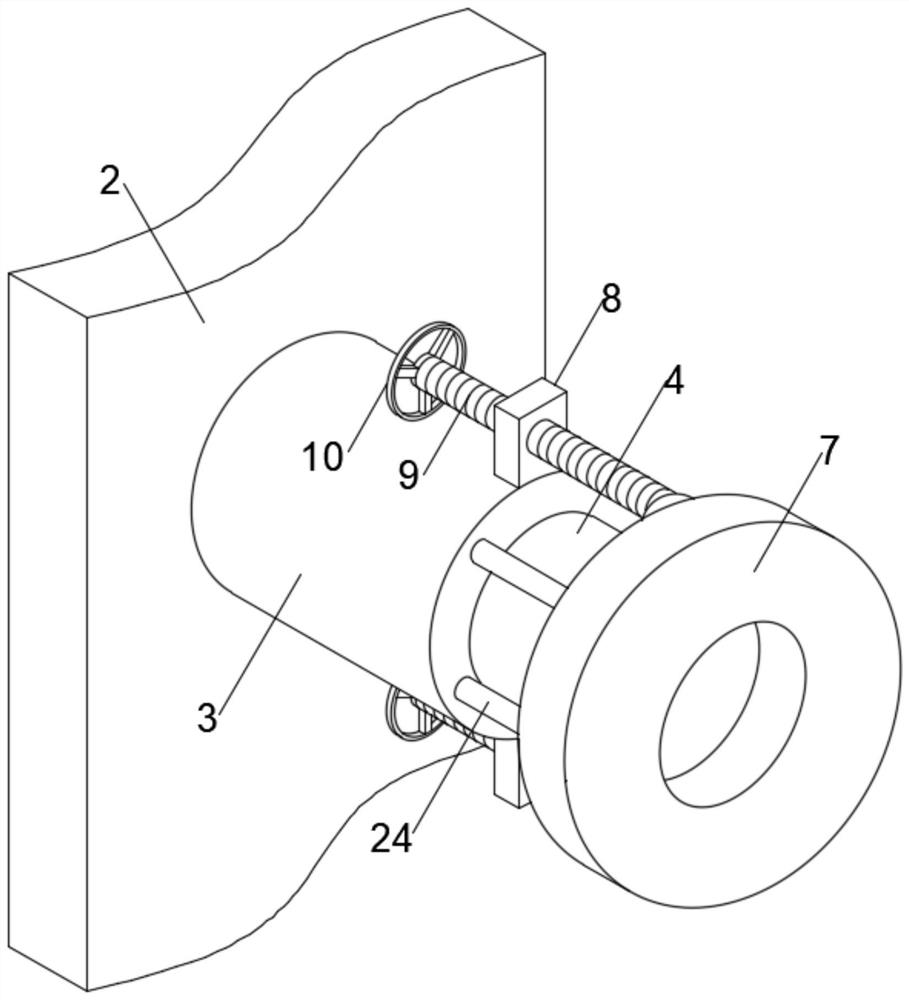

[0027] The telescoping adjustment mechanism includes a first cylinder 3, the first cylinder 3 is fixed on one side of the base plate 2, the inside of the first cylinder 3 is slidably inserted and connected with a second cylinder 4, and both sides of the second cylinder 4 are A slider 5 is fixedly provided, and the two sliders 5 are respectively connected to the slots provided on the inner wall of the first cylinder 3. One side of the slider 5 is fixedly provided with a first spring 6, and one end of the first spring 6 is connected ...

Embodiment 2

[0034]The protection mechanism comprises two mounts 14, and the two mounts 14 are respectively fixed on the top and bottom of the other side of the spacer ring 7, and one side of the mount 14 is movably connected with a supporting plate 15, and the two supporting plates 15 There are two piercing rods 16 between them, the supporting plate 15 is provided with a perforation opposite to the piercing rod 16, both ends of the piercing rod 16 are provided with a limit mechanism, and the outer part of the piercing rod 16 is provided with a third spring 26 , both ends of the third spring 26 are fixedly provided with slip rings 25, the slip rings 25 are slidably connected to the outside of the rod 16, the outside of the third spring 26 is sleeved with a protective cover 27, and the two ends of the protective cover 27 are respectively connected to the two One end of a slip ring 25 is fixedly connected, one side of the mounting seat 14 is provided with a concave plate 11, the concave plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com