A method for preparing diamond/aluminum composite material by liquid-solid separation

A technology of aluminum composite materials and diamond, which is applied in the field of high thermal conductivity diamond/aluminum composite materials, can solve the problems of difficult popularization and application and high manufacturing cost, and achieve the effect of increasing compactness and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

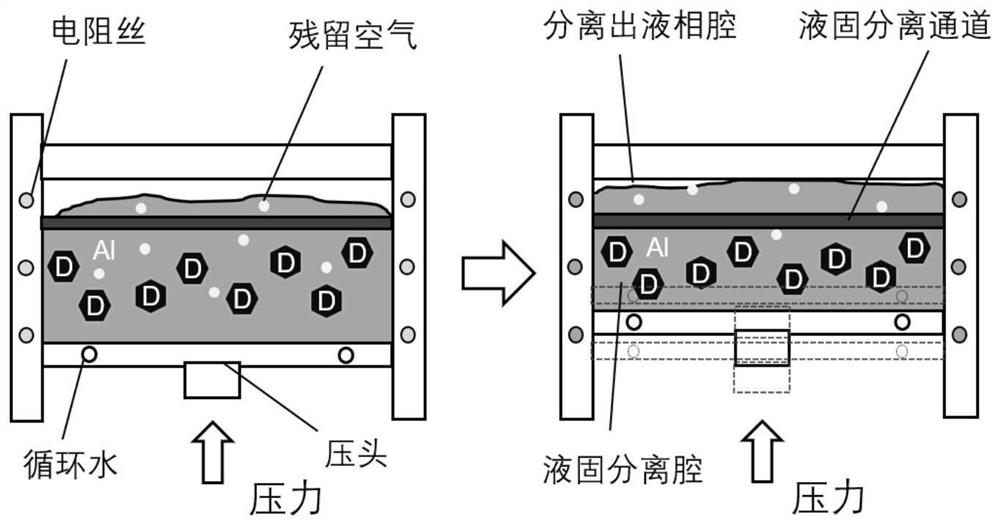

[0045] use figure 1 The liquid-solid separation system shown prepares a diamond / aluminum composite material with a diamond content of 30-70vol.%.

[0046] The diamond particles and the metal aluminum powder are mixed in a certain ratio (1:9-3:7) and mechanically mixed in a planetary ball mill for a mixing time of 1-48 hours to make a mixed powder.

[0047] The mixed powder is put into a cold-pressing mold, placed in a press and held at a pressure of 50-300MPa for 0.5-5 minutes to make a cold-pressed billet of a certain size.

[0048] The cold-pressed billet is directly placed in a special mold system with a liquid-solid separation channel. 2 Heating to 640-720° C. for 10-60 minutes under atmosphere protection conditions to prepare a liquid-solid mixed molten slurry in which diamond solid phase particles and liquid metal aluminum coexist.

[0049] The liquid-solid mixed molten slurry passes through the liquid-solid separation channel with a gap of 0.5-5mm in width, and under ...

specific Embodiment approach 2

[0052] This embodiment is different from the specific embodiment one in that:

[0053] Diamond particles and metallic aluminum powder are mechanically mixed in a 3D mixer.

[0054] The cold-pressed billet is heated under an inert gas protection atmosphere to prepare a liquid-solid mixed molten slurry.

[0055] The liquid-solid separation channel is a circular hole with a diameter of 0.5-5mm.

[0056] The layer-by-layer solidification of the composite material is realized by forced cooling with an external cold iron.

specific Embodiment approach 3

[0058] This embodiment is different from the specific embodiment one in that:

[0059] The cold-pressed billet is placed in the pass with H 2 After being heated to a liquid-solid mixed molten state in an atmosphere-protected heating furnace, it is transferred to a special mold system with a liquid-solid separation channel.

[0060] The layer-by-layer solidification of the composite material is achieved by forced air cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com