Method for recovering plutonium from strong acid waste liquid

A technology of waste liquid and strong acid, applied in the direction of improving process efficiency, can solve the problems of large radioactive sludge deposition, difficulty, volume reduction treatment improvement, etc., and achieve fast and efficient decontamination effect, excellent selective quantitative carrying capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Recovery of plutonium from strong acid waste liquid includes the following steps:

[0030] (1) dissolving neodymium trioxide in 8M nitric acid to prepare a 0.11M neodymium nitrate solution as a carrier solution;

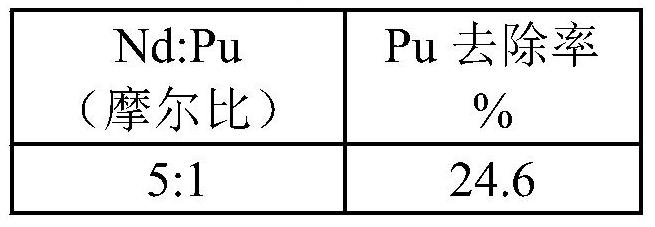

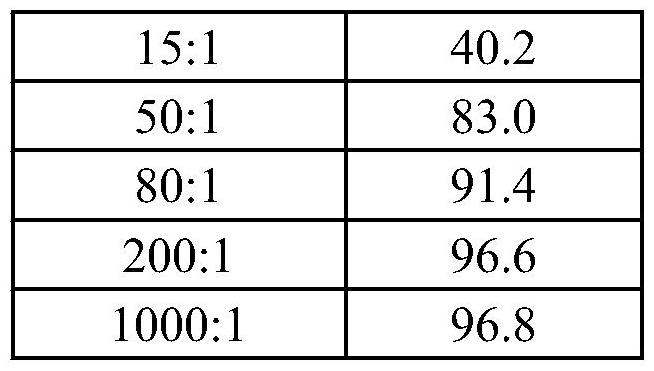

[0031] (2) get the plutonium-containing waste liquid with nitric acid concentration of 4M, after pre-analysis by liquid scintillation, add the neodymium nitrate carrier solution prepared in step (1) according to the atomic molar ratio of different neodymium and plutonium; Fluoride precipitates the carrier, so add 0.5mol / L NH 2 OH·HCl solution, heated at 50°C for 20min, to reduce the hexavalent plutonium in the waste liquid to a low valence state; continue to add 0.5M hydrofluoric acid solution dropwise, slowly add, stir and mix, and leave for 20min, wherein the amount of hydrofluoric acid is based on The total amount of neodymium ions in the solution is calculated, so that all precipitations are appropriately excessive;

[0032] (3) centrifuging the obtained...

Embodiment 2

[0039] Recovery of plutonium from strong acid waste liquid includes the following steps:

[0040] (1) dissolving neodymium trioxide in 8M nitric acid to prepare a 0.11M neodymium nitrate solution as a carrier solution;

[0041] (2) get the plutonium-containing waste liquid with nitric acid concentration of 4M, after pre-analysis by liquid scintillation, add the neodymium nitrate carrier solution prepared in step (1) according to the atomic molar ratio of neodymium and plutonium as 200:1; then add 0.5 M's NH 2 OH·HCl solution, heated at 50℃ for 20min to reduce the hexavalent plutonium in the waste liquid;

[0042] (3) Slowly add 0.5M hydrofluoric acid to the pretreated waste liquid in step (2), and take the supernatant liquid for analysis during the formation of neodymium fluoride precipitation. Since neodymium is pink in the aqueous solution, neodymium in the solution The concentration and absorbance follow Lambert Beer's law, the concentration of neodymium in the solution i...

Embodiment 3

[0049] (1) dissolving neodymium trioxide in 8M nitric acid to prepare a 0.1M neodymium nitrate solution as a carrier solution;

[0050] (2) get the plutonium-containing waste liquid with nitric acid concentration of 8M, after pre-analysis by liquid scintillation, add the neodymium nitrate carrier solution prepared in step (1) according to the atomic molar ratio of neodymium and plutonium as 200:1; then add 0.5 M's NH 2 The OH·HCl solution is heated and reduced to remove the hexavalent plutonium in the solution;

[0051] (3) Slowly add 0.5M hydrofluoric acid under stirring to the pretreated waste liquid in step (2), the amount of hydrofluoric acid added can make 2% of the carrier agent precipitate after calculation, and the generated carrier precipitate is filtered After separation, this step was repeated, and the two partial precipitates were washed with 5% hydrofluoric acid and then collected and dried.

[0052] (4) add 30mL 4M nitric acid solution and 1g boric acid to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com