Industrial process fault diagnosis method based on information fusion

A fault diagnosis and industrial process technology, applied in the direction of program control, instrument, test/monitoring control system, etc., can solve problems such as inability to adapt, and achieve the effect of high fault diagnosis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

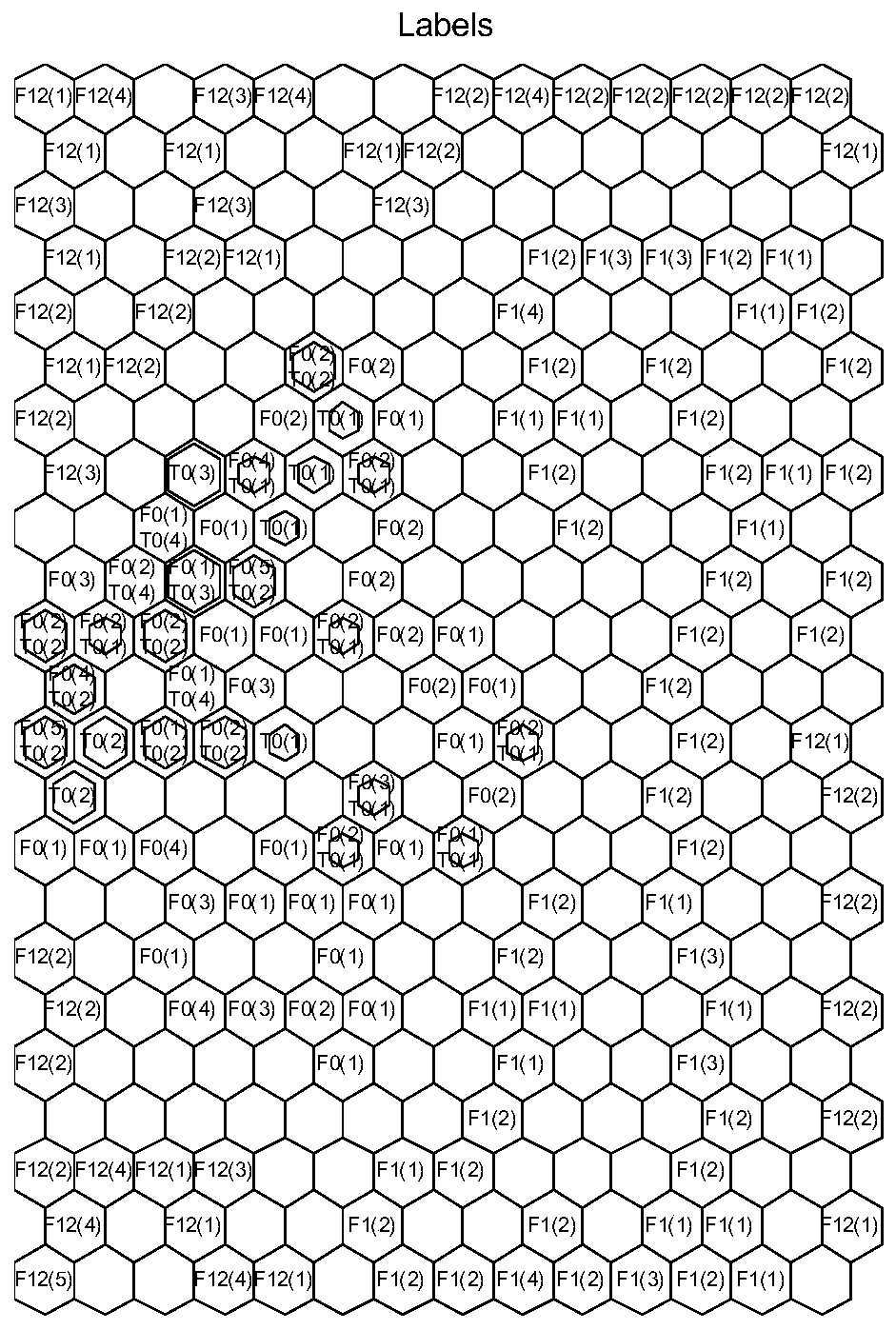

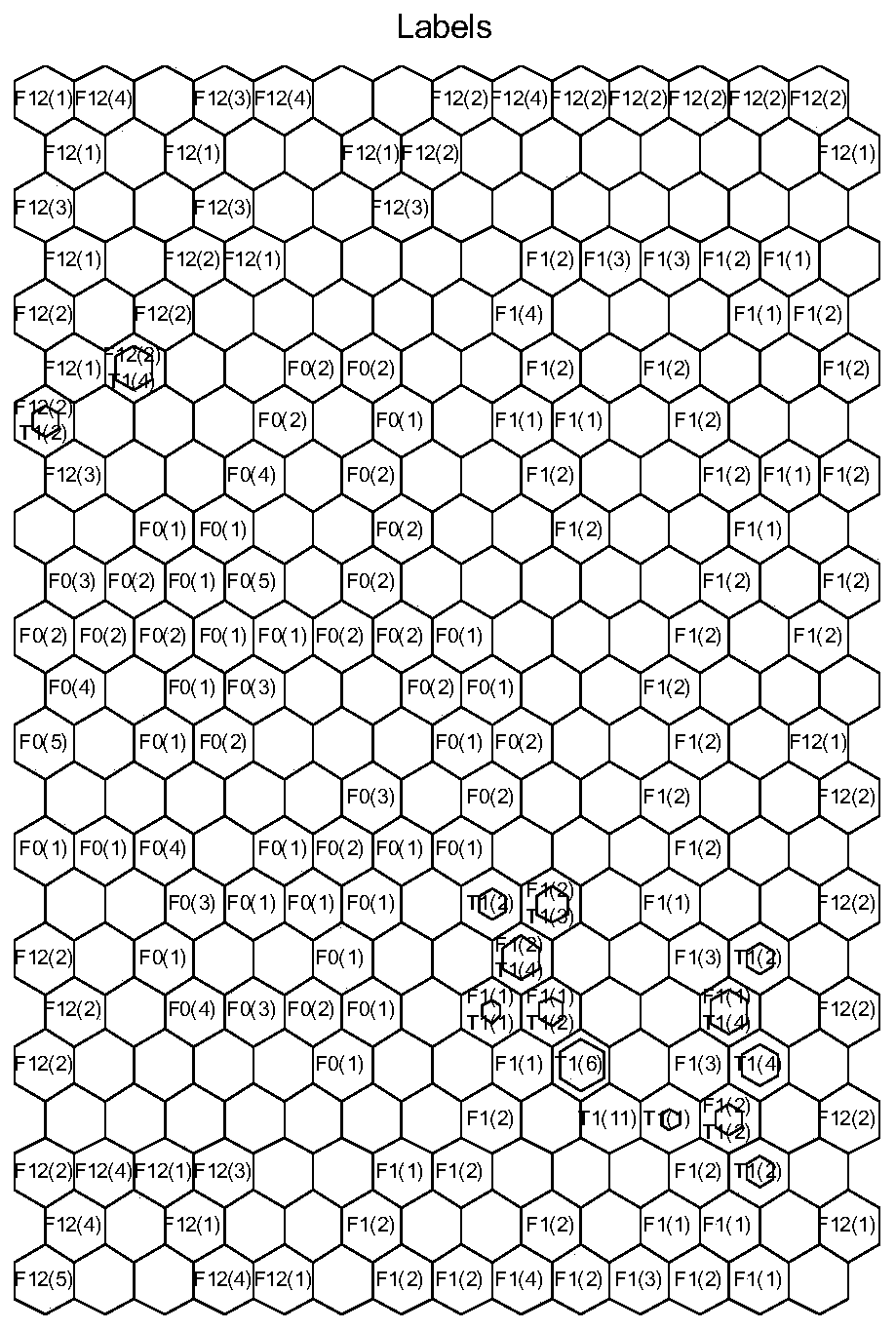

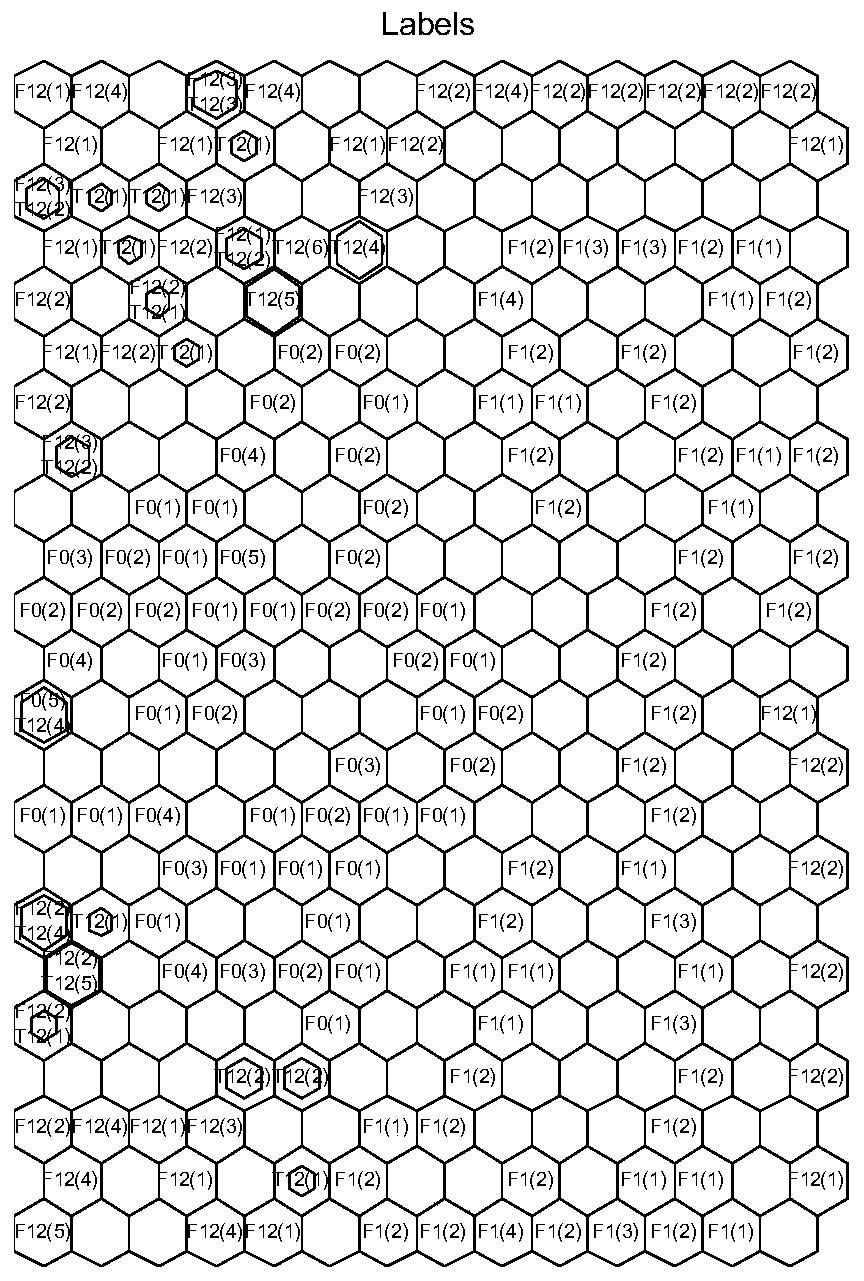

Image

Examples

Embodiment

[0048] The data of the industrial process comes from the chemical process simulation experiment of TE (Tennessee Eastman-Tennessee-Eastman) in the United States, and the prototype comes from the actual production process of Tennessee Eastman Chemical Company. TE process is a commonly used standard problem, which can better simulate some typical characteristics of actual complex industrial systems, so it is widely used in the research of typical chemical process fault diagnosis. The whole process includes 5 main units: reactor, condenser, compressor, steam separator and stripper. The whole TE process has 4 reactants, 2 products, an inert component and a by-product. The whole process contains a total of 53 state variables, which are 12 operating variables and 41 measurement variables, but only 52 state variables are actually used. Among them, 41 measured variables consist of 22 continuous measured variables (sampled by the system every 3 minutes) and 19 component measured varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com