Safety protection method for carrying manipulator and carrying manipulator

A safety protection and manipulator technology, applied in the field of handling manipulators, can solve problems such as safety accidents and workpiece damage, and achieve the effects of avoiding safety hazards, preventing sudden changes in air pressure, and ensuring safe and reliable handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

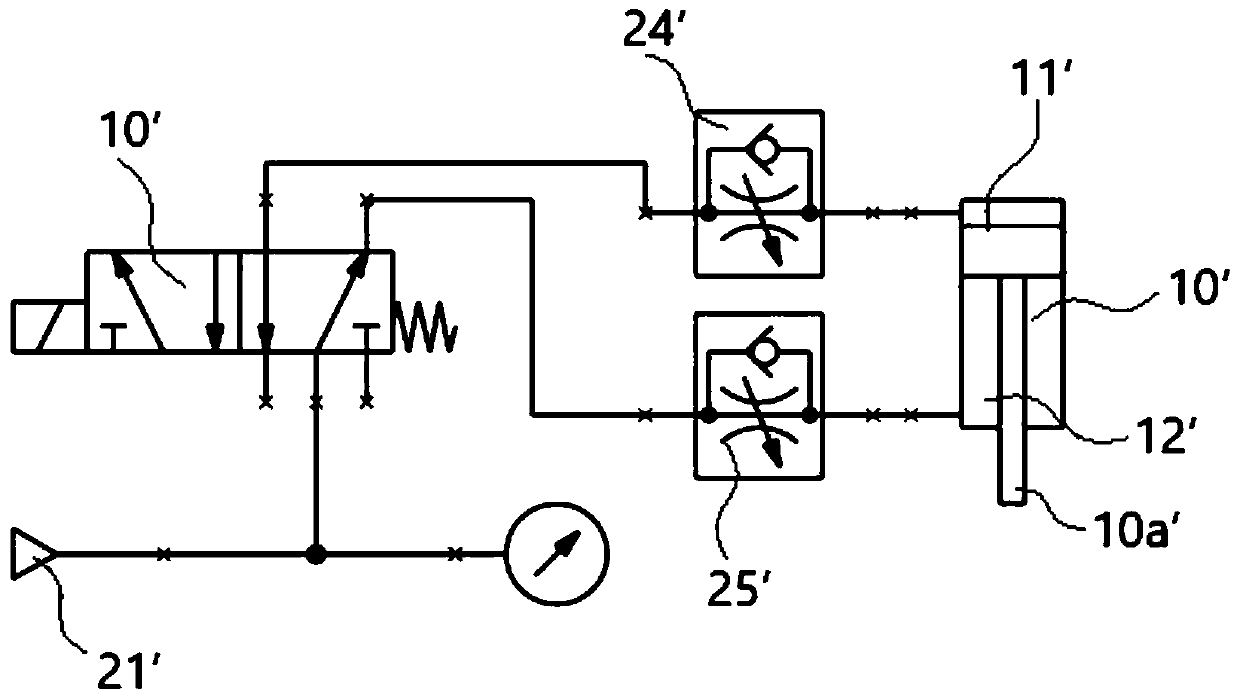

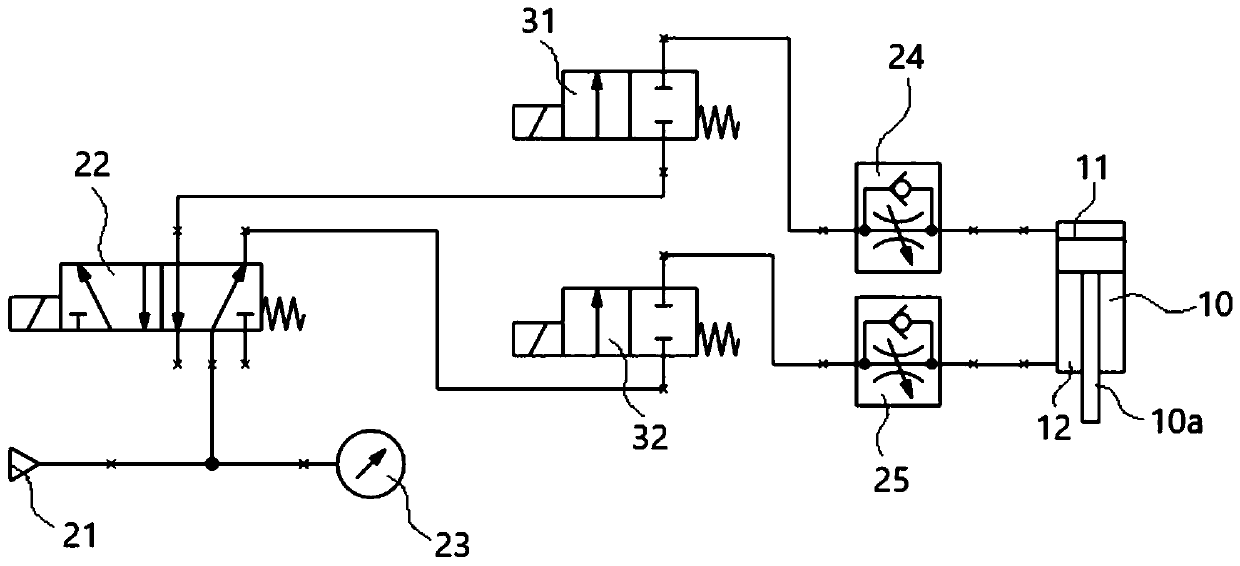

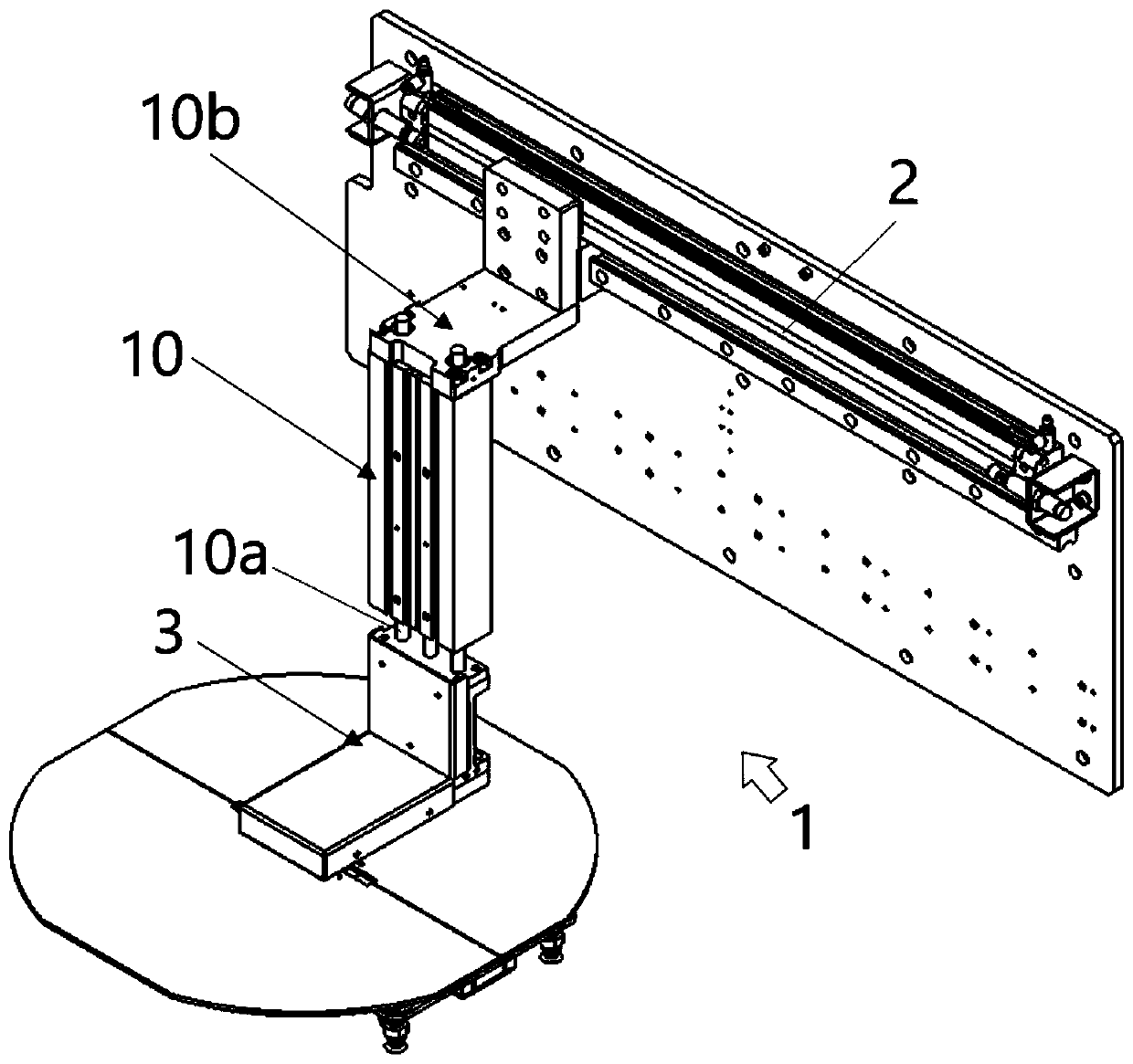

[0028] Example 1: see figure 2 As shown, a safety protection method for a handling manipulator, the handling manipulator includes a double-acting cylinder 10, the handling manipulator performs up and down stroke movement under the drive of the double-acting cylinder 10, the first gas chamber 11 and the second air chamber of the double-acting cylinder 10 An external gas source supply circuit is provided between the gas chambers 12; the external gas source supply circuit includes an external air pressure source 21, and the external air pressure source 21 selectively injects air pressure into the first gas chamber 11 and the second gas chamber 12 through a multi-position five-way valve, Preferably, in this embodiment, the multi-position five-way valve adopts a two-position five-way valve 22, and the external air pressure source 21 is connected to an air pressure gauge 23; wherein, the safety protection methods include:

[0029] A first normally-off two-way valve 31 is provided b...

Embodiment 2

[0034] Embodiment 2: A handling manipulator, including a hydraulic cylinder, the handling manipulator moves up and down under the driving action of the hydraulic cylinder, the first hydraulic chamber and the second hydraulic chamber of the hydraulic cylinder are driven by a hydraulic supply circuit, and the hydraulic supply The circuit includes an external hydraulic source, and the external hydraulic source selectively injects hydraulic pressure into the first hydraulic chamber and the second hydraulic chamber through the two-position five-way valve; there is a first normally-off two-way valve between the two-position five-way valve and the first hydraulic chamber , and there is a second normally-off two-way valve between the two-position five-way valve and the second hydraulic chamber; state, the driving rod of the hydraulic cylinder performs vertical lifting movement under the switch control of the two-position five-way valve; The two-way valves are all in the power-off and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com