Health monitoring system and method for UPS vehicle

A technology of health monitoring system and power supply vehicle, applied in the direction of control device, etc., can solve the problems of inability to real-time monitoring of UPS power supply vehicle, poor user experience, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

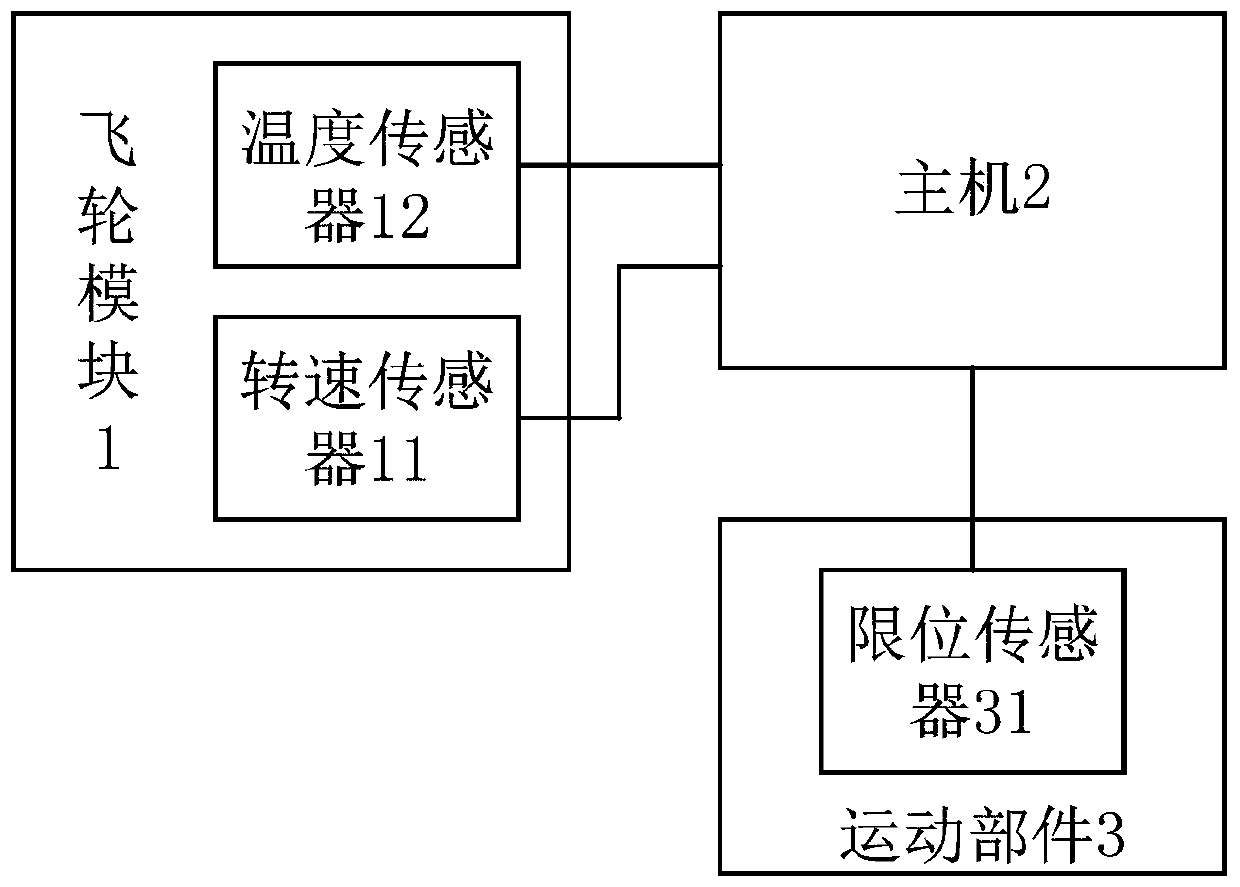

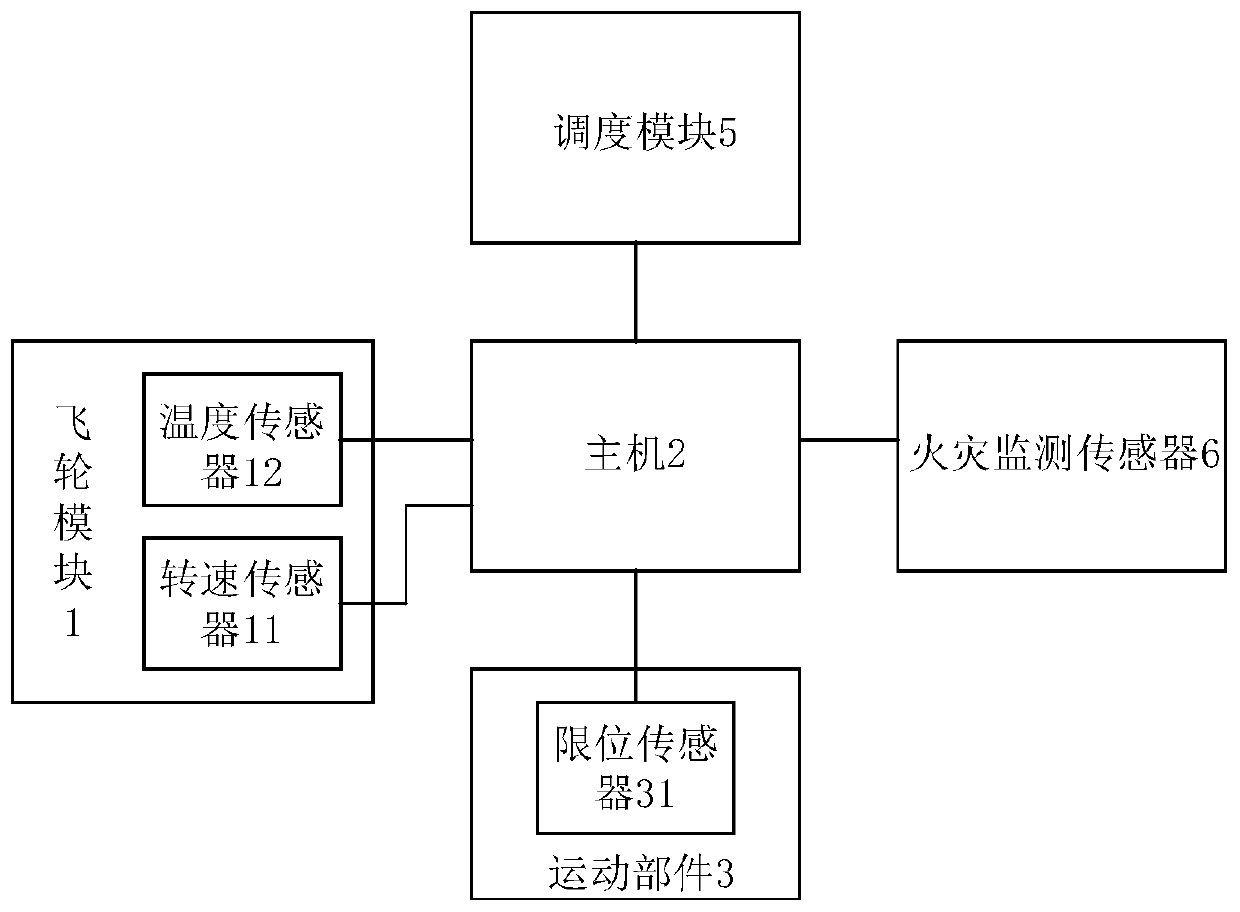

[0043] figure 1 It is a schematic diagram of a health monitoring system for a UPS power supply car provided by Embodiment 1 of the present invention.

[0044] refer to figure 1 , the system includes: a flywheel module 1, a host 2 and a moving part 3, wherein the flywheel module 1 includes a speed sensor 11 and a temperature sensor 12, and the moving part 3 is provided with a limit sensor 31;

[0045] The rotational speed sensor 11, the temperature sensor 12 and the limit sensor 31 are respectively connected with the host computer 2;

[0046] The rotational speed sensor 11 is used to collect the rotational speed of the flywheel to obtain the rotational speed value of the flywheel;

[0047] The temperature sensor 12 is used to collect the temperature of the flywheel to obtain the flywheel temperature value;

[0048] The limit sensor 31 is used to collect the wear of the moving parts to obtain the wear value;

[0049] Specifically, the speed sensor 11 can send the flywheel spee...

Embodiment 2

[0067] Figure 4 It is a flow chart of the health monitoring method for the UPS power supply car provided by Embodiment 2 of the present invention.

[0068] refer to Figure 4 , applied to the health monitoring system of the UPS power supply car as described above, the method comprises the following steps:

[0069] Step S101, collecting the rotational speed of the flywheel to obtain the rotational speed value of the flywheel;

[0070] Step S102, collecting the temperature of the flywheel to obtain the temperature value of the flywheel;

[0071] Step S103, collecting the wear of the moving parts to obtain the wear value;

[0072] Step S104, comparing the flywheel speed value with a preset speed threshold, and generating first fault information if the flywheel speed value reaches the preset speed threshold;

[0073] Step S105, comparing the flywheel temperature value with a preset temperature threshold, and generating second fault information if the flywheel temperature valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com