Calibration method of online moisture meter in cut tobacco making link for cigarettes

一种校验方法、水分仪的技术,应用在烟草行业领域,能够解决设备不稳定、不具备物料水分预测、预警功能、无法在线、实时检验水分仪准确性等问题,达到提高预测准确性、提高制丝工艺质量和生产效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

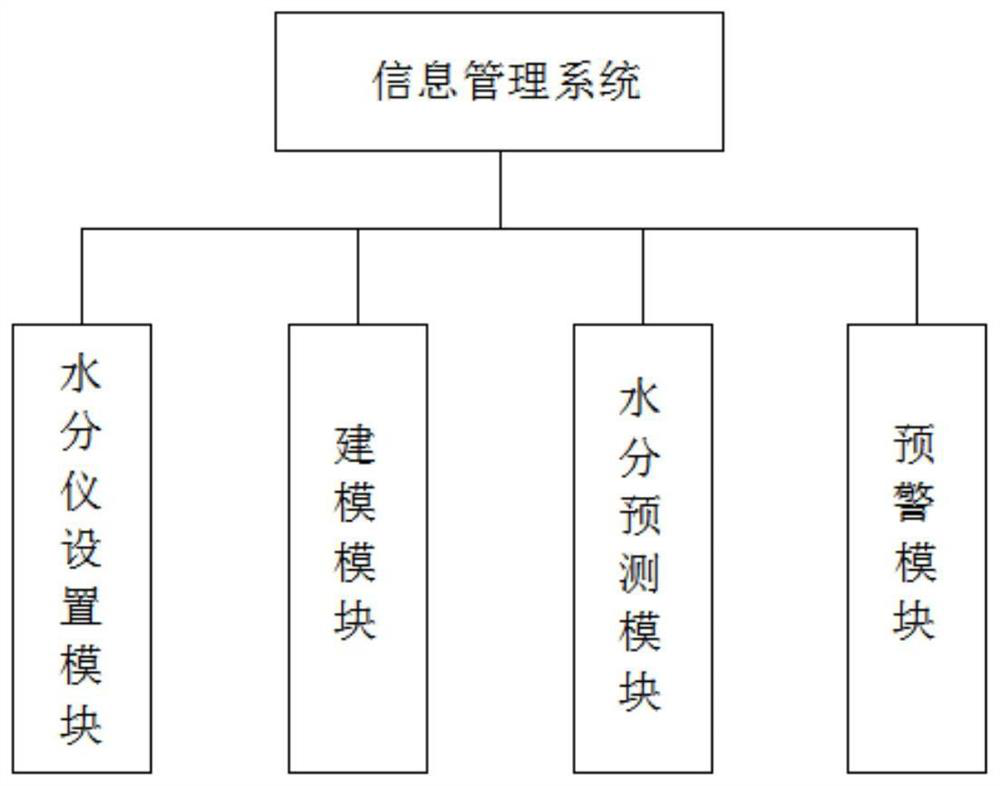

[0062] refer to figure 1 , An online moisture meter calibration system for cigarette silk making links, including an information management system, which stores historical production data, historical production data including historical batch parameters, and historical batch parameters specifically refer to the parameters of each process link of the silk production line Process parameters, production parameters, environmental parameters, etc., take the thin plate drying machine of the drying process as an example:

[0063] The process parameters include the moisture at the outlet of the veneer dryer, the inlet moisture of the veneer dryer, and the temperature of the drum of the veneer dryer; the outlet / inlet moisture is the key indicator of the system;

[0064] The production parameters include the opening of the steam film valve of the veneer dryer, the hot air temperature of the veneer dryer, the opening of the veneer dryer, the frequency of the underground fan of the veneer...

Embodiment 2

[0119]A method for verifying an online moisture meter in the process of tobacco silk making, the method is applied to the online moisture meter verification system in the process of tobacco silk making in Example 1, and the method includes the following steps:

[0120] Step one, data collection

[0121] Data source: Corresponding historical production data in the silk line information management system;

[0122] Step 2, the setting of the moisture meter in the production line

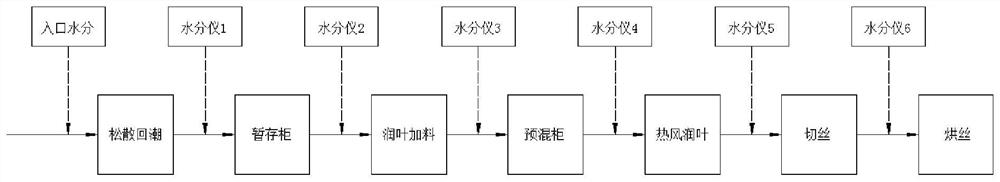

[0123] Place the moisture meter setting module at the front end of the process of loose moisture regaining, temporary storage cabinet, leaf moisturizing feeding, premixing cabinet, hot air moisturizing, shredding, and drying of the silk production line, and define each moisture meter;

[0124] Step 3, model establishment

[0125] Through the modeling module, the calibration model of the loose moisture regain moisture meter, the calibration model of the moisture meter for moisturizing and feeding, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com