Preparation method of anion exchange membrane for alkaline fuel cell and anion exchange membrane

An anion exchange membrane and fuel cell technology, which is applied in fuel cells, circuits, electrical components, etc., can solve problems such as poor mechanical properties and low ion exchange capacity of anion exchange membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 Preparation of chloromethylated SEBS

[0045] ① Weigh 5g of SEBS (number average molecular weight 130000, styrene content 58%) into a three-necked flask filled with 300mL chloroform (the three-necked flask is equipped with a condenser tube, a thermometer and a mechanical stirring rod), and mechanically stir for 2 hours. Allow SEBS to dissolve completely.

[0046] ②Put the three-neck flask in an ice-water bath to lower the SEBS solution to 0°C, add 4.6g of paraformaldehyde and 19.63mL of trimethylchlorosilane, stir mechanically for 30 minutes, then add 4.36g of SnCl4 dropwise in the ice-water bath, and dropwise Afterwards, react at room temperature for 18 h.

[0047] ③ Pour the reaction mixture in ② into absolute ethanol, and a white precipitate precipitates out. Filter the white precipitate, and dry the white precipitate in an oven at 60°C.

[0048] ④ Dissolve the white precipitate obtained in ③ in chloroform first, then precipitate and filter in ethanol,...

Embodiment 2

[0049] The preparation of embodiment 2 2wt.% CSEBS solution

[0050] The CSEBS prepared in Example 1 was added into chloroform, and mechanically stirred at room temperature for 6 h to obtain a 2 wt.% CSEBS solution.

Embodiment 3

[0051] The preparation of embodiment 3 2wt.% BPEI solution

[0052] BPEI (number-average molecular weight: 25,000) was added into chloroform and mechanically stirred at room temperature for 6 h to obtain a 2 wt.% BPEI solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

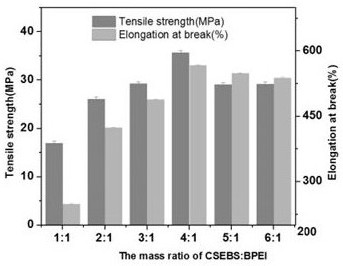

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com