Preparation and application of fluororesins with low ion exchange capacity

An ion-exchange, fluororesin technology, applied in the field of fluorine-containing polymer materials, can solve the problems of broken chemical bond position and breakage cannot be precisely controlled, mechanical properties, heat resistance, chemical corrosion resistance, durability reduction, fracture and other problems

Active Publication Date: 2010-12-29

SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, many research methods use high-energy ray irradiation to functionalize ETFE. One disadvantage of this irradiation method is that the C-C bond on the surface of the film is broken during the irradiation process. Precise control, the mechanical properties, heat resistance, chemical corrosion resistance and durability of the material itself will be reduced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

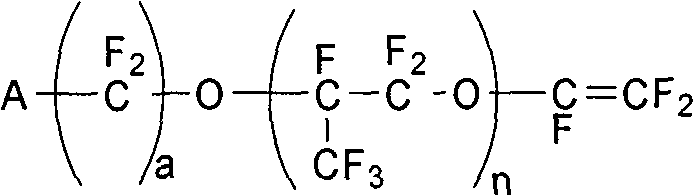

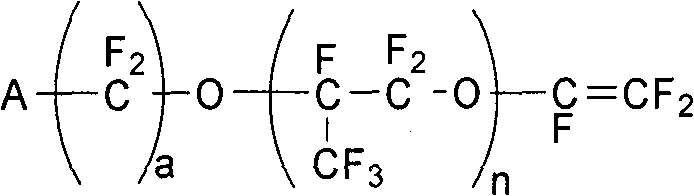

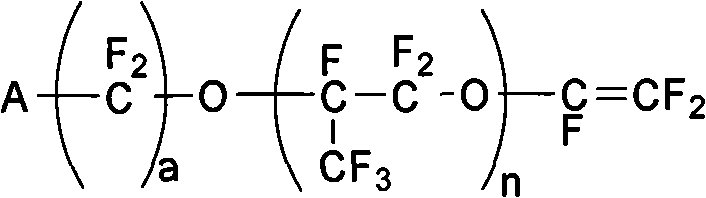

The invention discloses fluororesins with low ion exchange capacity and high mechanical strength, which comprise tetrafluoroethylene, ethylene and one or pluralities of monomers with structures illustrated by following general formulas (I): in the formulas, a=2-5, n=0-2; A is chosen from -COR0, -COOR1, -CONR2R3 or -CN; and R0-R3 are chosen from -CmH2m+1, wherein m=1-10. Molecular weight ranges from 150,000-650,000. Fluorine-contained polymers with ion exchanging function adopt an anticorrosive hastelloy melt spinning device to prepare polymer fibers with melt spinning serving as materials, the fibers are woven into fiber nets with the ion exchanging function via spinning technology, and the fiber nets serve as strengthening net materials of proton exchange membranes and chlor-alkali ion membranes, thereby achieving the purposes of simultaneously improving the capabilities of membrane materials in strengthening and increasing adhesion between the fibers and the membranes, increasing content of carboxylic acid ions and efficiently stopping back migration of hydroxyls.

Description

technical field The invention belongs to the field of fluorine-containing polymer materials, and relates to a class of fluorine resin with ion exchange function and its application as an ion exchange membrane reinforcing material. Background technique Since perfluorinated ion-exchange composite membranes have shown their talents in the chlor-alkali industry, the application of perfluorinated ion-exchange membranes has been extensively studied in countries all over the world. Whether perfluorinated ion exchange membranes are used in the chlor-alkali industry or in fuel cells, the currently known technologies need to be reinforced with reinforcing skeleton materials. Whether they are reinforced with microporous materials or fiber reinforced, these reinforcing materials are nothing more than PTFE. Ethylene, fusible polytetrafluoroethylene and a small amount of sacrificial fiber material for auxiliary purposes. These perfluorinated reinforcing materials are insulating materials...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F214/24B01J39/19

CPCY02E60/50

Inventor 高自宏秦胜李勇魏茂祥

Owner SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com