A kind of polymer composite electrolyte membrane and preparation method thereof

A technology of composite electrolyte membranes and polymers, applied in circuits, fuel cells, electrical components, etc., can solve the problems of low industrialization of electrospinning technology, high price of nanofiber membranes, increased process/raw material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] (1) Raw materials

[0128] Porous membrane: hydrophobic polytetrafluoroethylene porous membrane PM1;

[0129] Non-fluoropolymer electrolyte solution: sulfonated polyetheretherketone SPEEK1 / dimethylformamide solution, the concentration is 10wt%;

[0131] (2) Composite steps

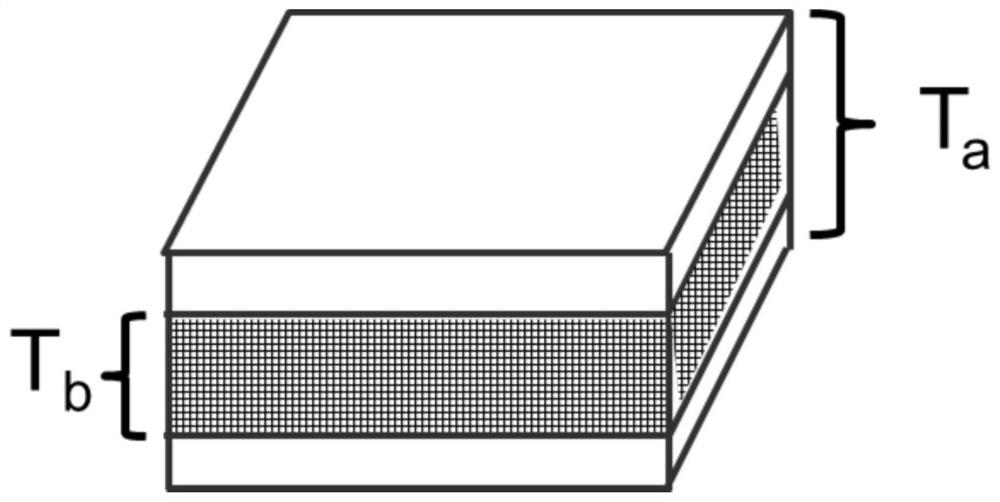

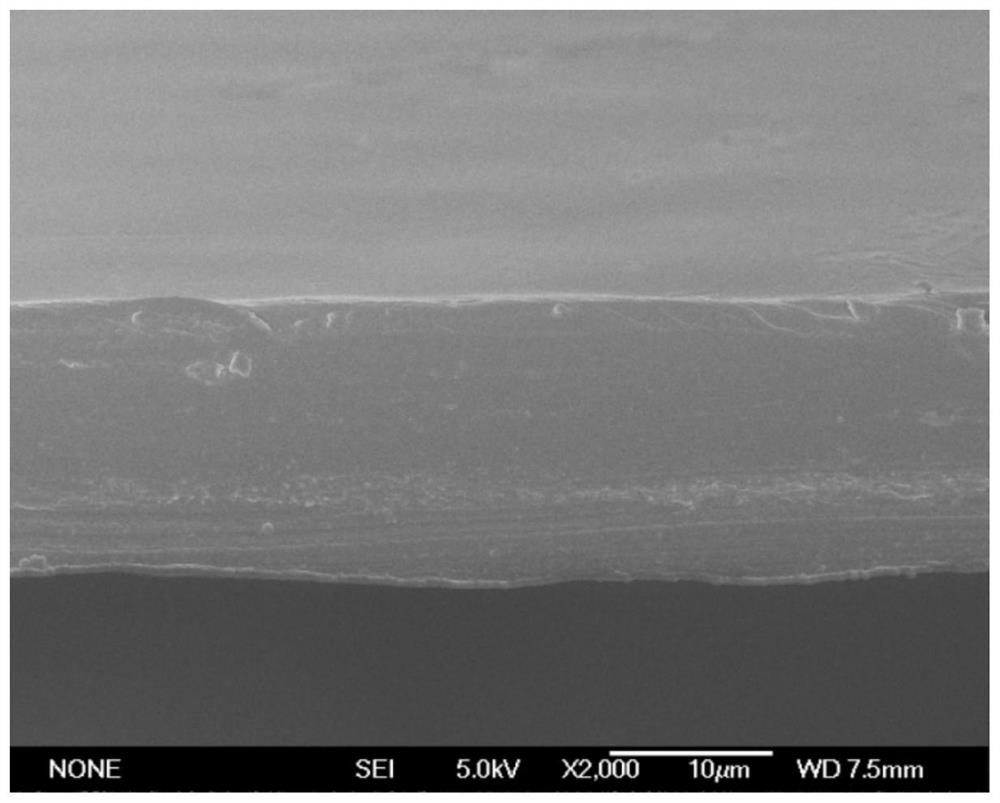

[0132] After the hydrophobic polytetrafluoroethylene porous membrane is fixed with an outer frame, a surface is soaked with a quantitative solvent, and the solvent content in the hydrophobic polytetrafluoroethylene porous membrane is 80% after soaking. The non-fluorine polymer electrolyte solution is evenly cast on the soaked porous membrane, and then placed in a vacuum oven at 60°C for drying (vacuum degree 100Pa), to obtain a composite membrane with a composite surface. Then use the same method to compound the other surface, and after drying, a polymer composite electrolyte membrane of non-fluoropolymer electrolyte and hydrophobic polytetrafluoroethylene porous membra...

Embodiment 2

[0138] (1) Raw material

[0139] Porous membrane: hydrophobic polytetrafluoroethylene porous membrane PM1;

[0140] Non-fluoropolymer electrolyte solution: sulfonated polyetheretherketone SPEEK1 / dimethylformamide solution, the concentration is 5wt%;

[0142] (2) Composite steps

[0143] After the hydrophobic polytetrafluoroethylene porous membrane is fixed with an outer frame, a surface is soaked with a quantitative solvent, and the solvent content in the hydrophobic polytetrafluoroethylene porous membrane is 80% after soaking. The non-fluorine polymer electrolyte solution is evenly cast on the soaked porous membrane, and then placed in a vacuum oven at 60°C for drying (vacuum degree 100Pa), to obtain a composite membrane with a composite surface. Then, the other surface was composited by the same method, and after drying, a polymer composite electrolyte membrane of non-fluoropolymer electrolyte and hydrophobic polytetrafluoroethylene porous membr...

Embodiment 3

[0149] (1) Raw material

[0150] Porous membrane: hydrophobic polytetrafluoroethylene porous membrane PM3;

[0151] Non-fluoropolymer electrolyte solution: sulfonated polyetheretherketone SPEEK2 / dimethylformamide solution, the concentration is 5wt%;

[0153] (2) Composite steps

[0154] After the hydrophobic polytetrafluoroethylene porous membrane is fixed with an outer frame, a surface is soaked with a quantitative solvent, and the solvent content in the hydrophobic polytetrafluoroethylene porous membrane is 50% after soaking. The non-fluorine polymer electrolyte solution is evenly cast on the soaked porous membrane, and then placed in a vacuum oven at 60°C for drying (vacuum degree 100Pa), to obtain a composite membrane with a composite surface. Then, the other surface was composited by the same method, and after drying, a polymer composite electrolyte membrane of non-fluoropolymer electrolyte and hydrophobic polytetrafluoroethylene porous membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com