Steel truss arch bridge and construction method

A technology for steel truss arch bridges and construction passages, which is applied to bridges, bridge parts, bridge materials, etc., can solve problems such as failure to meet the bearing capacity requirements of bridge erection supports, inconvenience for workers to change operations, and difficulty in installing tie rods and beams. To achieve the effect of convenient adjustment of the position of the tie rod and the beam, convenient change operation, convenient continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

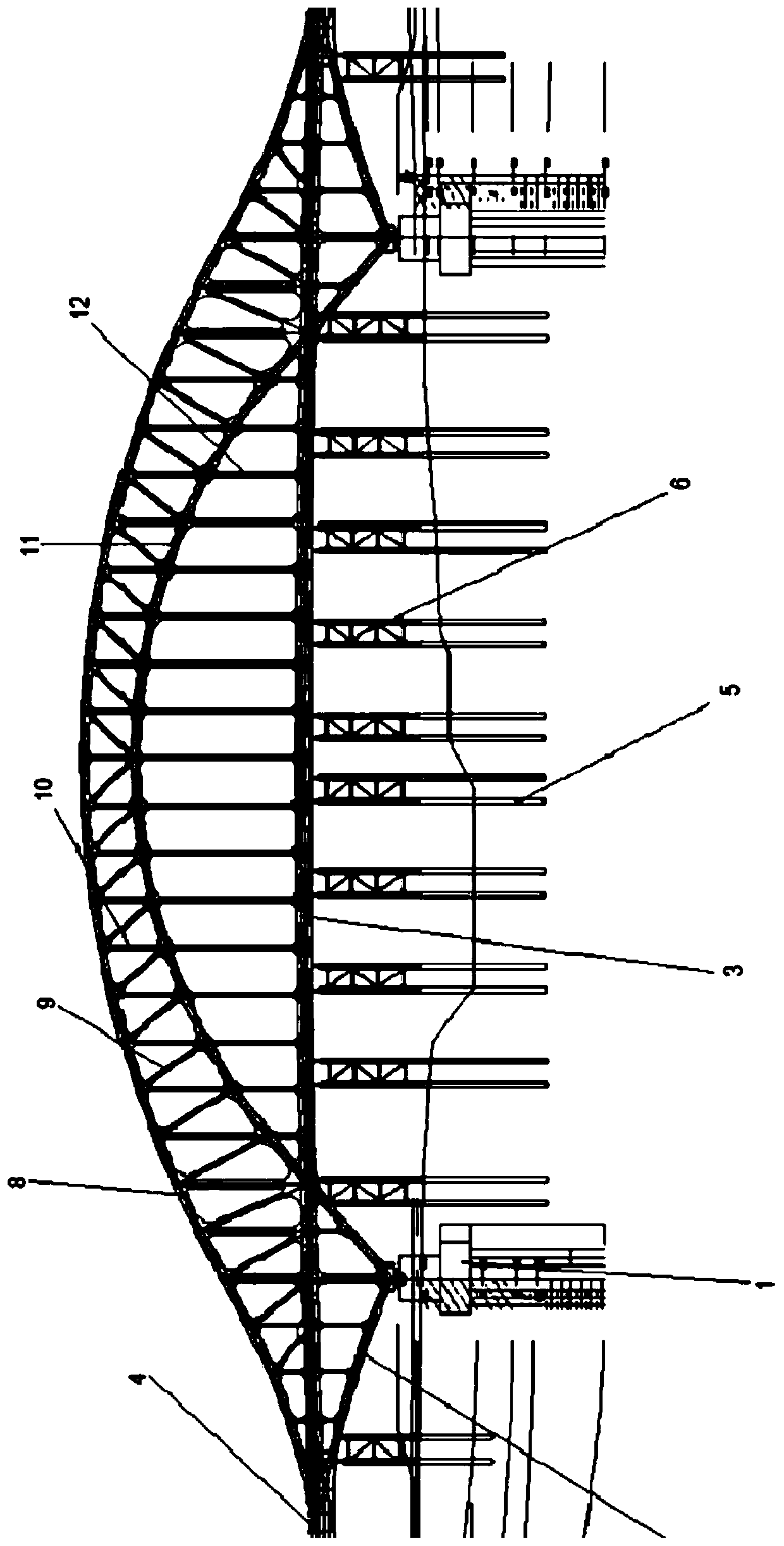

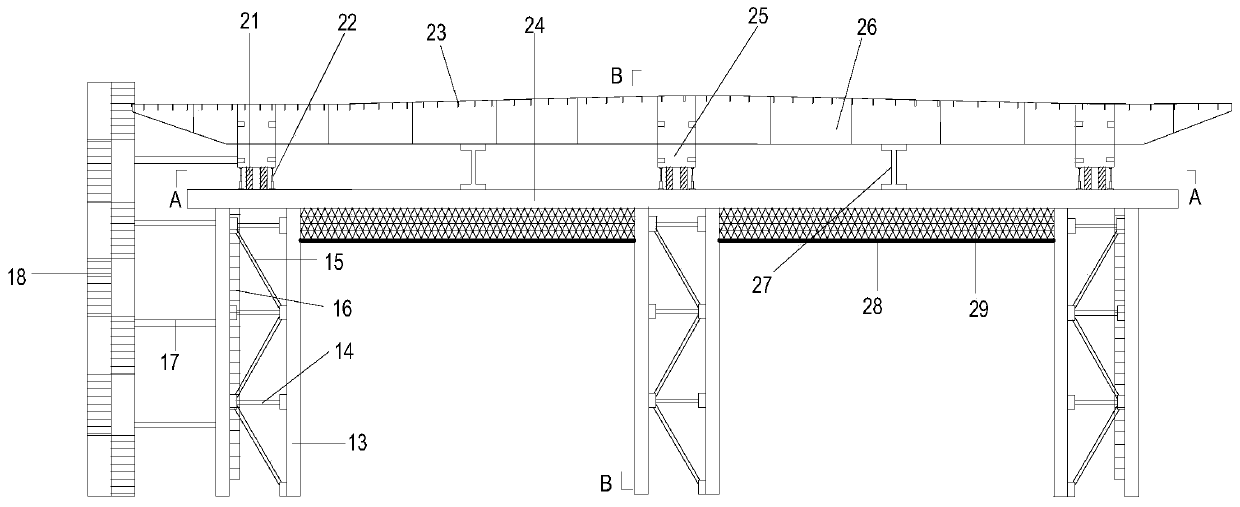

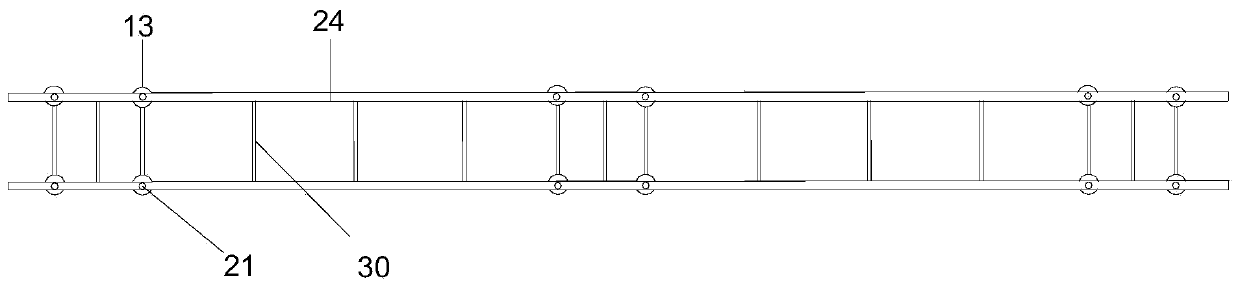

[0065] Such as Figure 1-Figure 18 As shown, a steel truss arch bridge includes a main pier 1 standing in the water close to the longitudinal banks, side-span buttresses 2 are vertically arranged in the water between the main pier 1 and the corresponding side banks, and side-span support piers 2 are located on the side-span support Between the piers 2, there are a plurality of steel pipe piles 5 distributed vertically and horizontally in the water. Mid-span tie rods 3 are connected between the steel pipe piles 5. A steel pipe pile adjacent to the column pier 1 is connected, each steel pipe pile 5 is connected with a temporary support pier 6, and each temporary support pier 6 is a lattice column formed by a plurality of vertical support steel pipes 13 , the lower end of each support steel pipe 13 is respectively fixed on the upper end of the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com