Circular blank holding device

A technology for clamping devices and blanks, which is applied in the direction of grinding workpiece supports, grinding machines, metal processing equipment, etc., can solve problems such as head warping, affecting normal production, and insufficient overturning force, and achieves strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

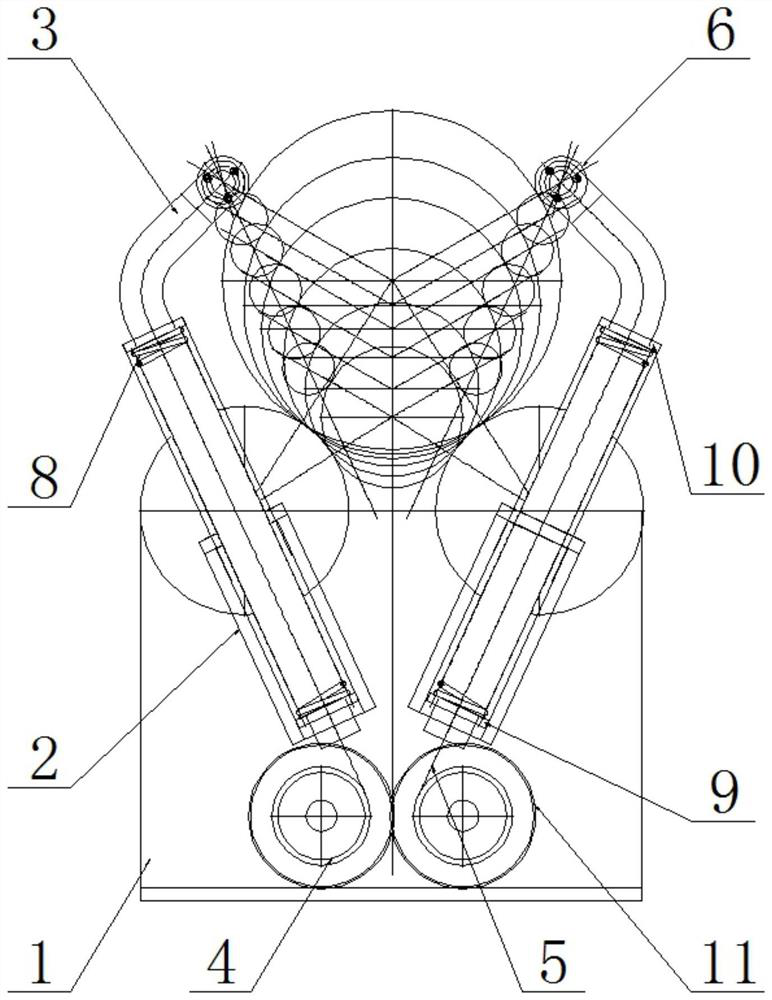

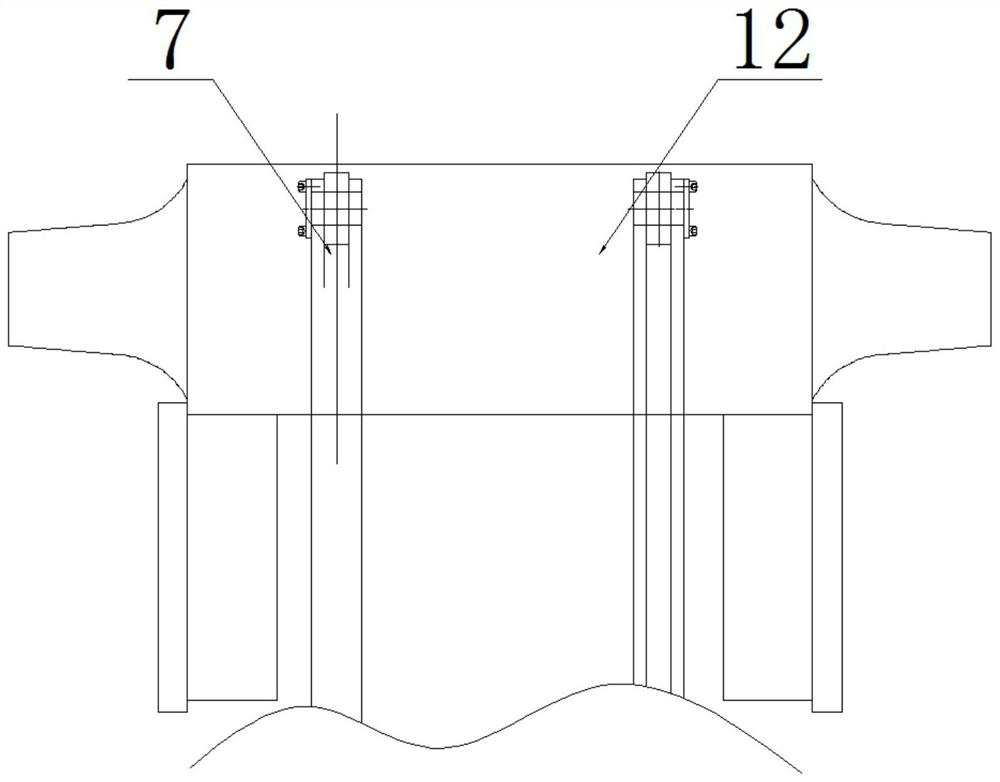

[0035] see figure 1 , figure 2 , a round blank holding device related to the present invention, which includes two bases 1 at the front and rear, both of which are set on the grinding trolley, and two bases 1 are symmetrically arranged on the left and right Guide sleeve 2, said guide sleeve 2 is inserted with a curved arm 3, and each guide sleeve 2 is provided with a reel 4 below, and a steel wire rope 5 is wound on the reel 4, and the lower end of the curved arm 3 is connected to the corresponding The steel wire rope 5 on the reel 4 is connected, and the reel can pull the curved arm downward by winding the steel wire rope, so that the curved arm slides downward in the guide sleeve, and finally the left and right curved arms hold the blank tightly;

[0036] The left and right guide sleeves 2 are arranged at a certain angle, so the curved ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap