Waste gas heat exchange device of gypsum type vacuum pressurization pouring tank

A technology of waste gas heat and exchange device, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of large environmental pollution, waste of energy, high noise, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

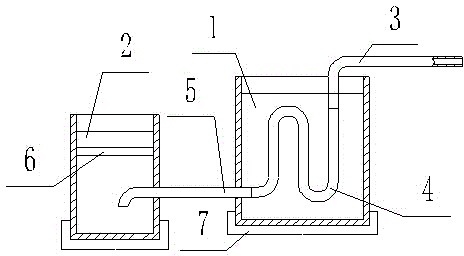

[0010] Example: such as figure 1 As shown, a gypsum type vacuum pressurized pouring tank waste gas heat exchange device includes a sewage bucket 2 and a hot water bucket 1, a heat exchanger 4 is arranged in the hot water bucket 1, and one end of the heat exchanger 4 is connected with The air inlet pipe 3 is connected with a water outlet pipe at the other end, and the end of the water outlet pipe far away from the heat exchanger 4 is connected with the sewage bucket 2, and the upper part of the sewage bucket 2 is provided with a layer of air filter layer 6, and the sewage bucket 2 and the hot water bucket 1 The bottoms are provided with fixed pads 7; the heat exchanger 4 is threadedly connected with the air inlet pipe 3 and the air outlet pipe 5.

[0011] The invention is simple in structure and easy to use, and mainly solves the noise and dust pollution caused by the waste gas discharge generated in the production process of the gypsum-type investment precision casting vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com