Feeding control device and control method for cross-over rolling-up unit

A technology of control device and control method, which is applied in the direction of program control and program control in conveyor control device, sequence/logic controller, etc., can solve the problem of overflow edge out of tolerance, steel coil falling, and difficulty in judging whether the center of the steel coil is in line with the The center alignment of the saddle can prevent instability and tipping, prevent instability and fall, and ensure safe and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing embodiment, the present invention is described in further detail:

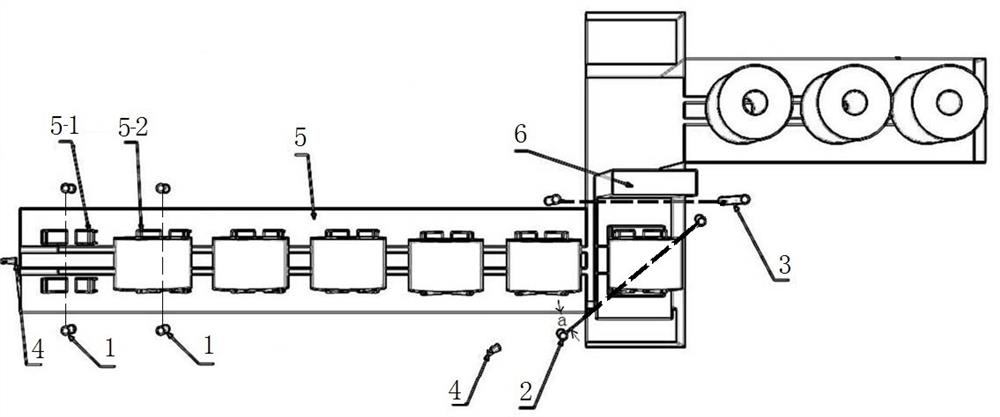

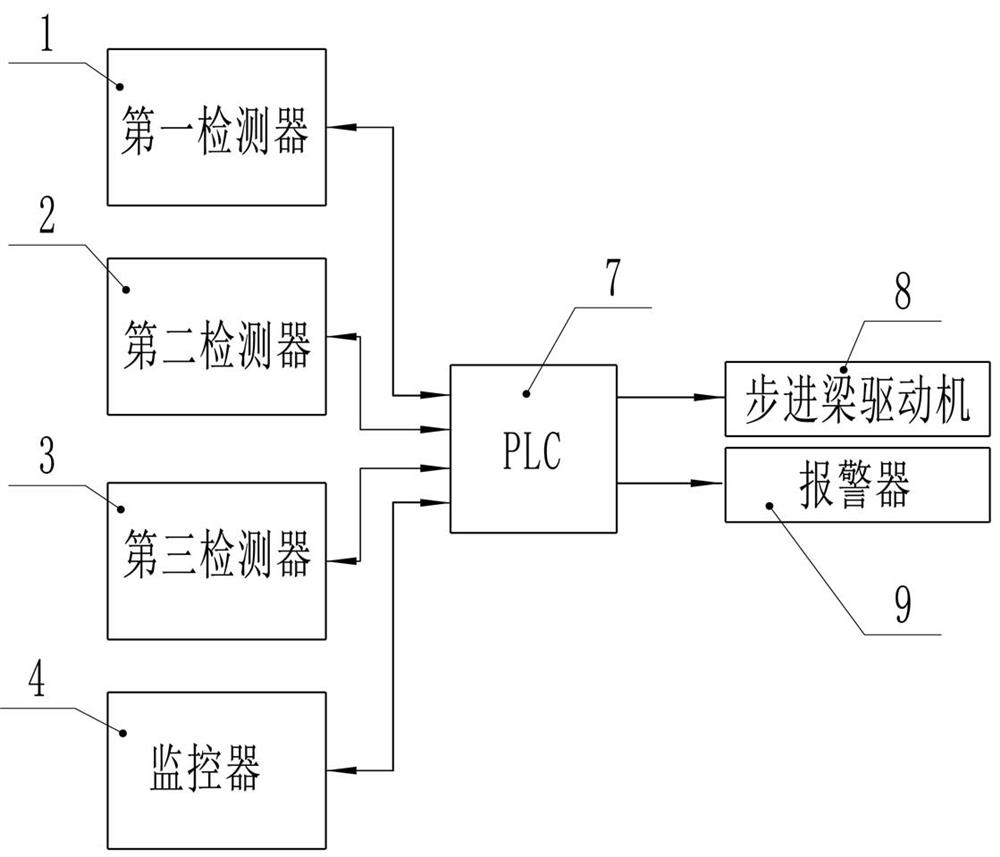

[0017] figure 1 , figure 2 The shown cross-rolling unit feeding control device includes a first detector 1, a second detector 2, a third detector 3 and a monitor 4; at least one pair of first detectors 1, the first detector in this embodiment There are two pairs of devices, which are respectively arranged on both sides of the input end of the entry walking beam across the turning unit, and correspond to the first saddle 5-1 and the second saddle 5-2 at the input end of the entry walking beam 5. The distance between each pair of first detectors 1 is 2000mm, and the first detector 1 is an ultrasonic ranging sensor, which is used to detect whether the center of the steel coil to be turned is consistent with the center of the saddle; the second detector 2 The position of the intersection angle a between the entrance walking beam 5 and the turning machine 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap