Object rotation detection method suitable for mechanical hand at-hand operation

A target rotation and detection method technology, applied in the field of robotics, can solve problems such as complex visual processing algorithms, unfavorable software and hardware integration of robot control systems, and easy failure of rotation detection methods, so as to improve capabilities and avoid operational errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

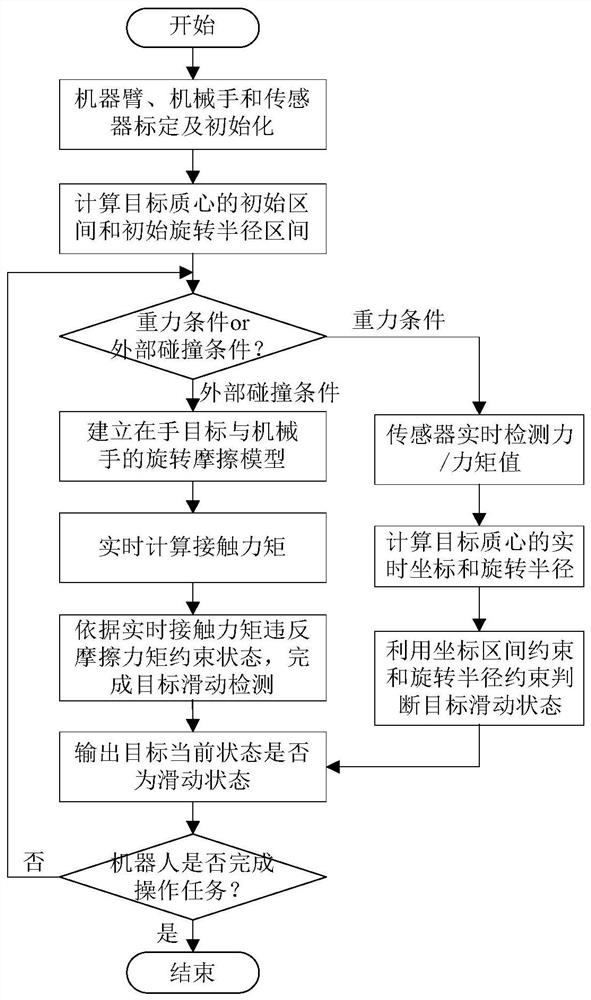

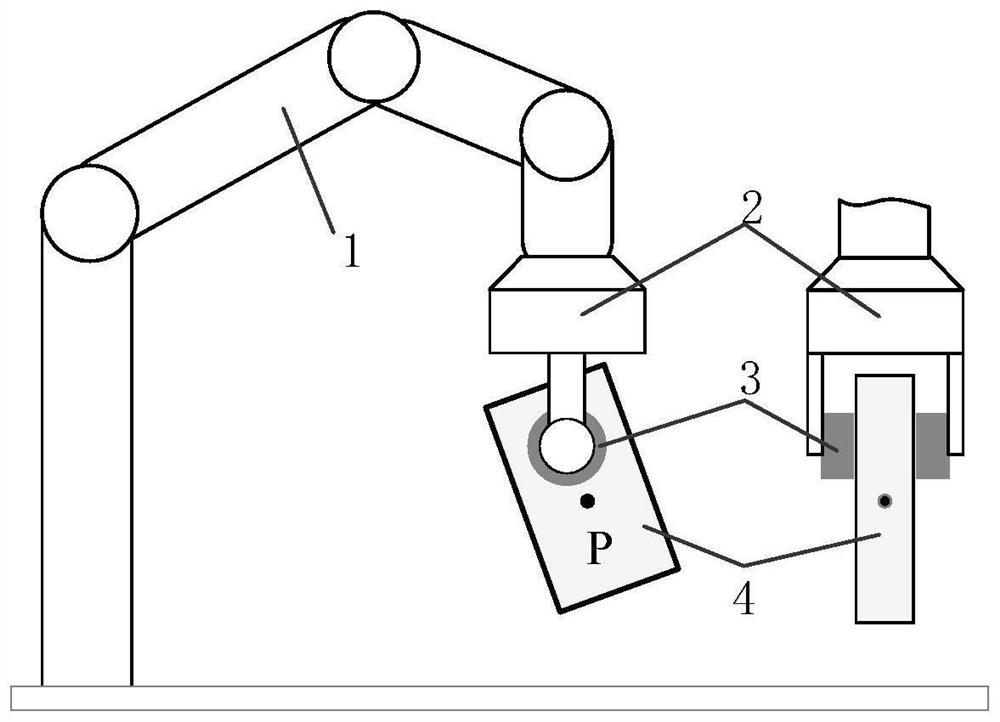

[0028] Such as figure 1 As shown, the target rotation detection method suitable for manipulator in-hand operation is suitable for robot target grasping and target manipulation, especially the rotation detection of the operating target after the manipulator grabs the target. The systems involved in the rotation detection of the job target, as attached figure 2 As shown, it includes a manipulator 1 , a manipulator 2 , a force / torque sensor 3 and an operation target 4 .

[0029] The robotic arm 1 described above is a multi-axis robotic arm with common path planning functions.

[0030] The manipulator 2 is a two-finger manipulator and can perform online posture adjustment. The manipulator can be installed at the end of the manipulator 1 , and cooperate with the manipulator 1 to grasp the work object 4 .

[0031] The force / torque sensor 3 can be integrated at the fingertip of the manipulator 2, and has the ability to detect three-dimensional force and three-dimensional torque. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com