Patents

Literature

34results about How to "Improve the level of intelligent operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

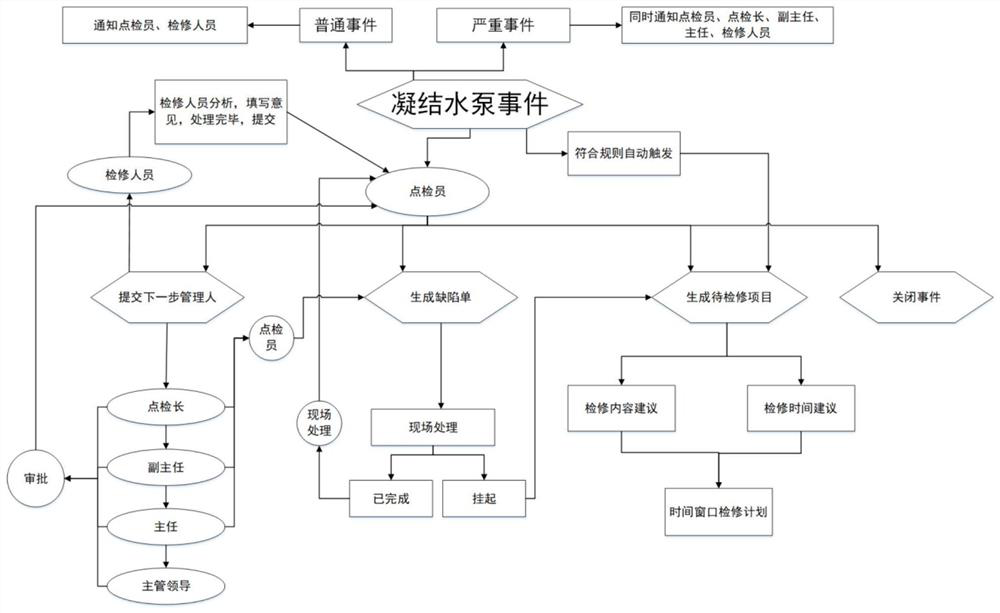

Intelligent unmanned inspection system of coal conveying system

ActiveCN109941700ASave electricityReduce labor costsConveyorsCleaningAutomotive engineeringState management

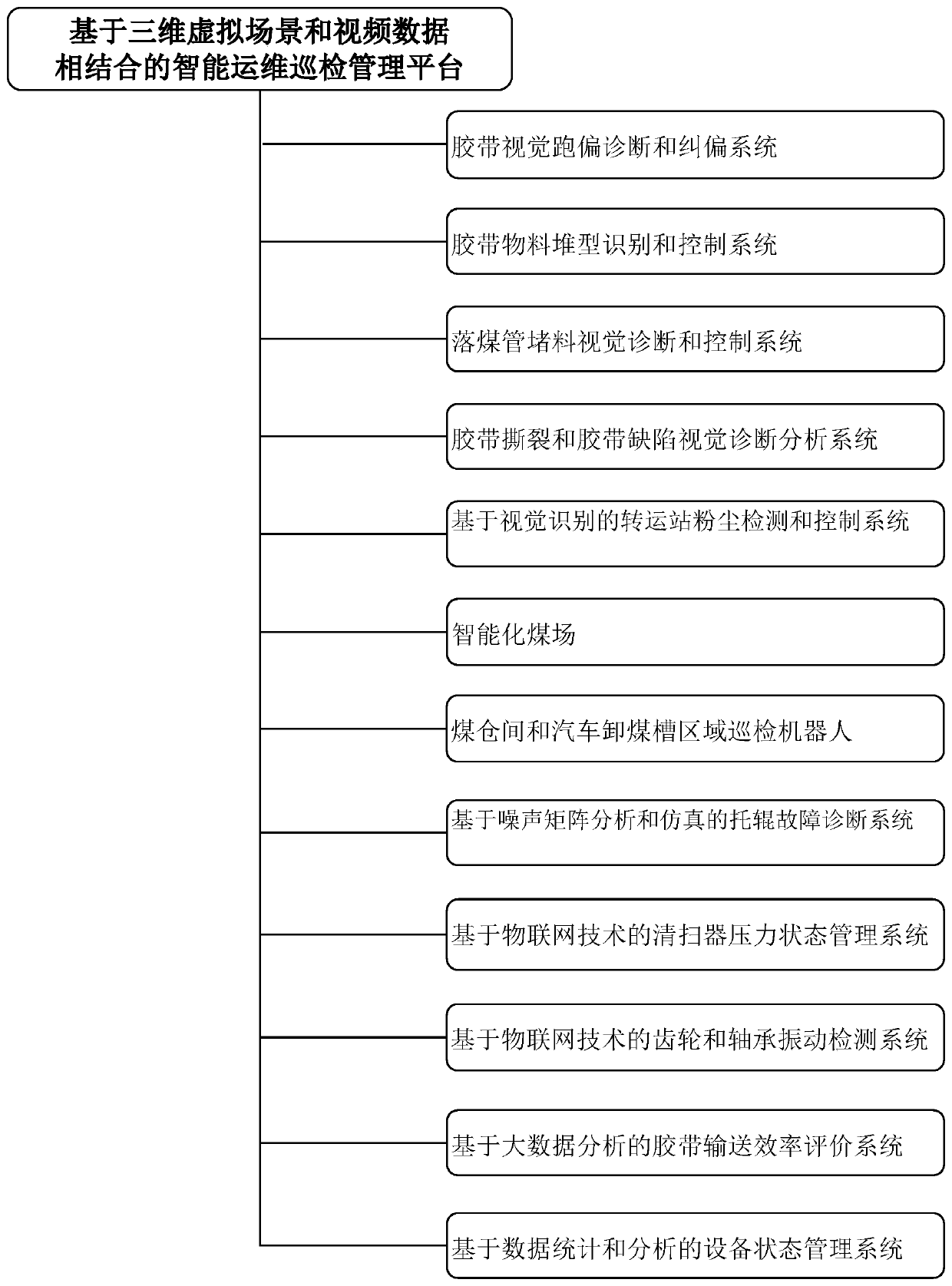

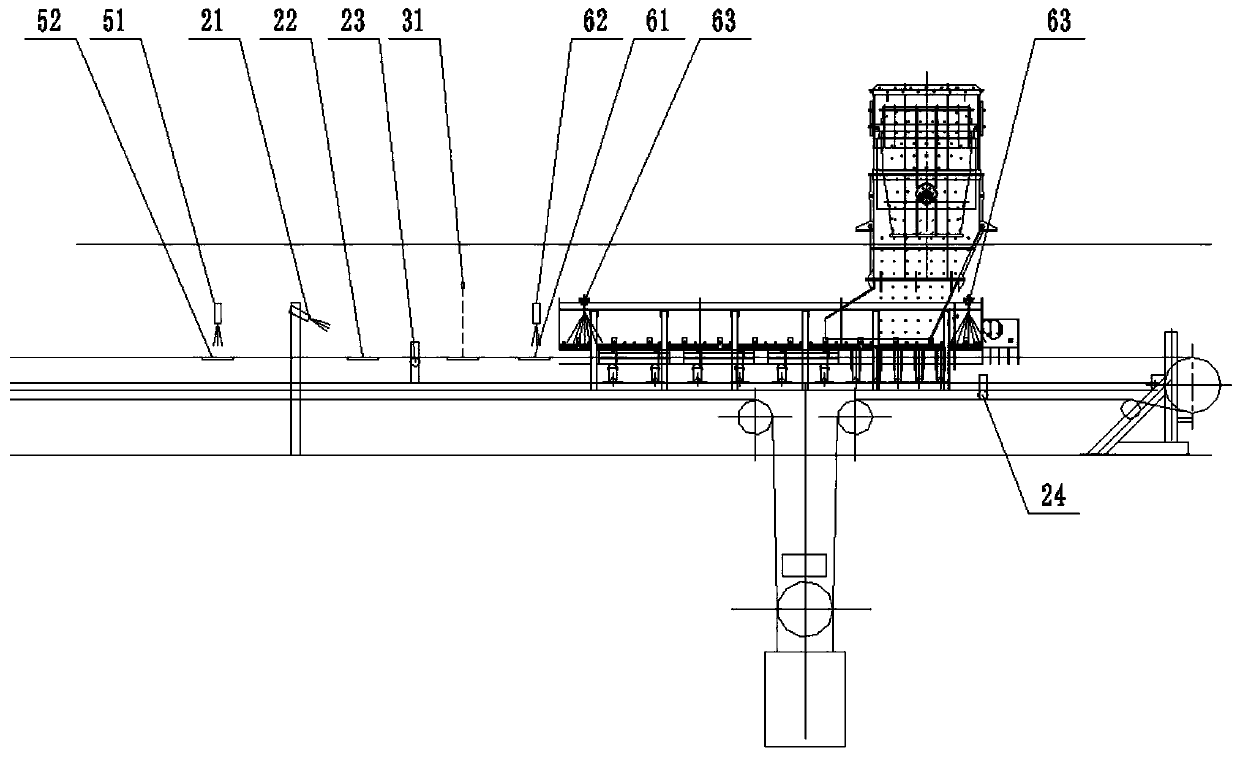

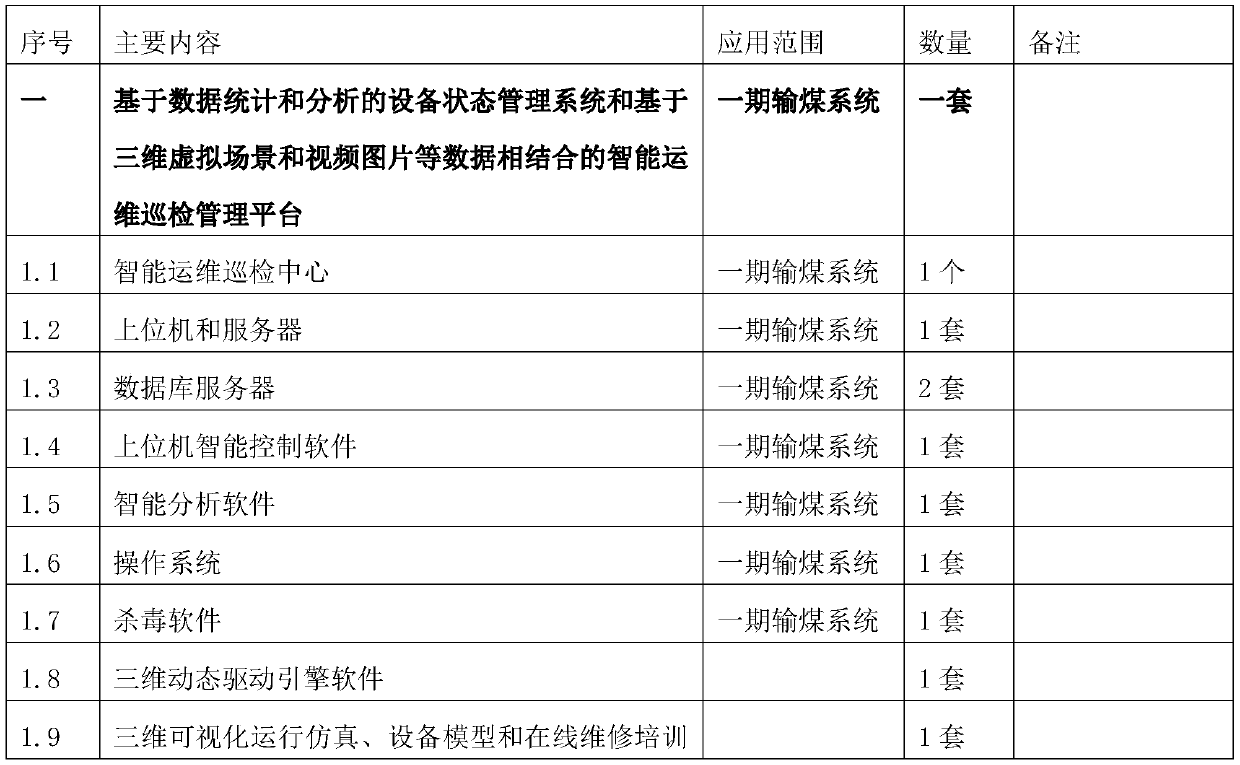

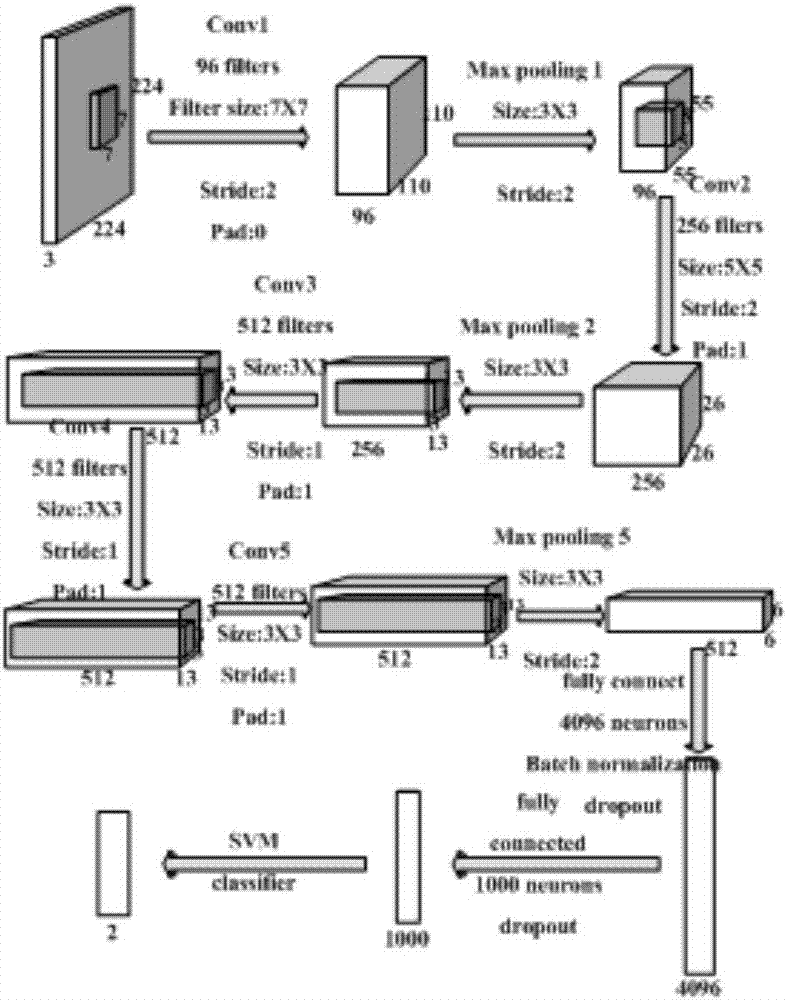

The invention discloses an intelligent unmanned inspection system of a coal conveying system. The intelligent unmanned inspection system of the coal conveying system comprises an intelligent operationand maintenance inspection management platform based on a three-dimensional virtual scene and combined with video data, an adhesive tape visual deviation diagnosing and correcting system, an adhesivetape material stacking identification and control system, a coal falling pipe material blocking visual diagnosis and control system, an adhesive tape tearing and adhesive tape defect visual diagnosisanalysis system, a visual identification based forwarding station dust detection and control system, an intelligent coal yard, a bunker bay and automobile coal unloading tank area inspection robot, anoise matrix analysis and simulation based carrier roller fault diagnosis system, the internet of things technology based sweeper pressure state management system, the internet of things technology based gear and bearing vibration detection system, a big data analysis based adhesive tape conveying efficiency evaluation system and a data statistics and analysis based device state management system, wherein the adhesive tape visual deviation diagnosing and correcting system, the adhesive tape material stacking identification and control system, the coal falling pipe material blocking visual diagnosis and control system, the adhesive tape tearing and adhesive tape defect visual diagnosis analysis system, the visual identification based forwarding station dust detection and control system, the intelligent coal yard, the bunker bay and automobile coal unloading tank area inspection robot, the noise matrix analysis and simulation based carrier roller fault diagnosis system, the internet ofthings technology based sweeper pressure state management system, the internet of things technology based gear and bearing vibration detection system, the big data analysis based adhesive tape conveying efficiency evaluation system and the data statistics and the analysis based device state management system are connected with the intelligent operation and maintenance inspection management platform. According to the system, a whole coal conveying system is monitored and controlled in real time, self-accumulation and learning capability is achieved, and the unmanned and intelligent inspection system is realized.

Owner:湖北凯瑞知行智能装备有限公司

Unmanned aerial vehicle positioning method based on computer vision

InactiveCN106895824AAchieve positioningRealize local precise positioningPhotogrammetry/videogrammetryScene recognitionUncrewed vehicleComputer vision

The invention discloses an unmanned aerial vehicle positioning method based on computer vision capable of realizing local precise positioning in a signal barrier region. The unmanned aerial vehicle positioning method based on computer vision realizes local precise positioning of an unmanned aerial vehicle by combining a computer vision technology with a pseudo phase distance ranging technology, endows the unmanned aerial vehicle with a work capacity in a non-intervisible environment and changes the condition that an existing unmanned aerial vehicle only can be operated and transmit videos in an intervisible environment, and further extends the work distance of the unmanned aerial vehicle and extends the adaptive capacity of the operating condition. Meanwhile, dependence of the unmanned aerial vehicle on an operator is reduced greatly, so that the complexity of manual operation is reduced. More operating tasks are dehumanized, the risk of severe consequences due to microoperation of the operator is greatly reduced, the safety of line patrol of the unmanned aerial vehicle is enhanced, and the operating intelligent level of the unmanned aerial vehicle can be greatly enhanced. The method is of practical significance in enhancing the integral level of a patrol operation. The method is suitable for being popularized and applied in the technical field of unmanned aerial vehicle.

Owner:SICHUAN POWER EHV OVERHAUL

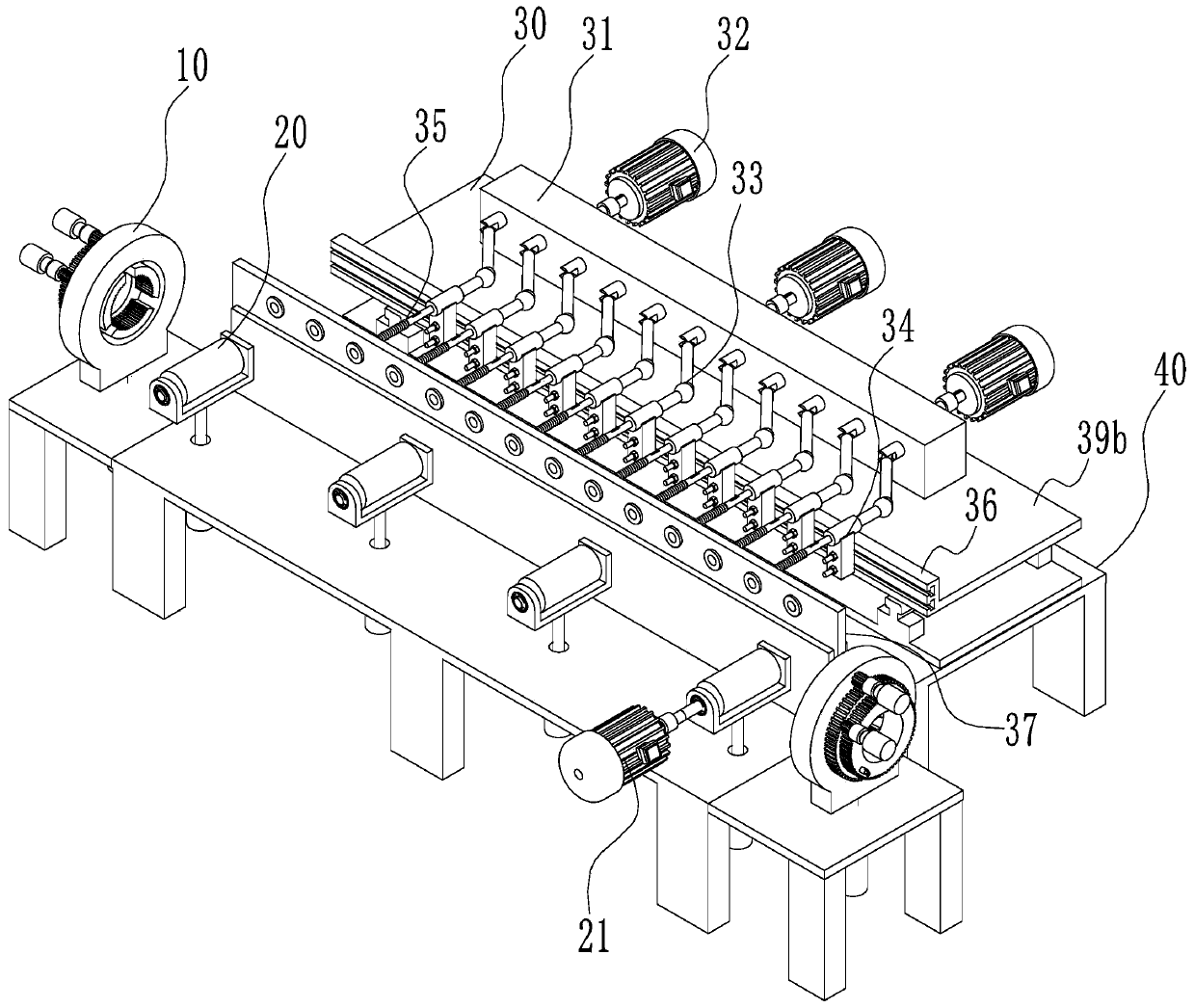

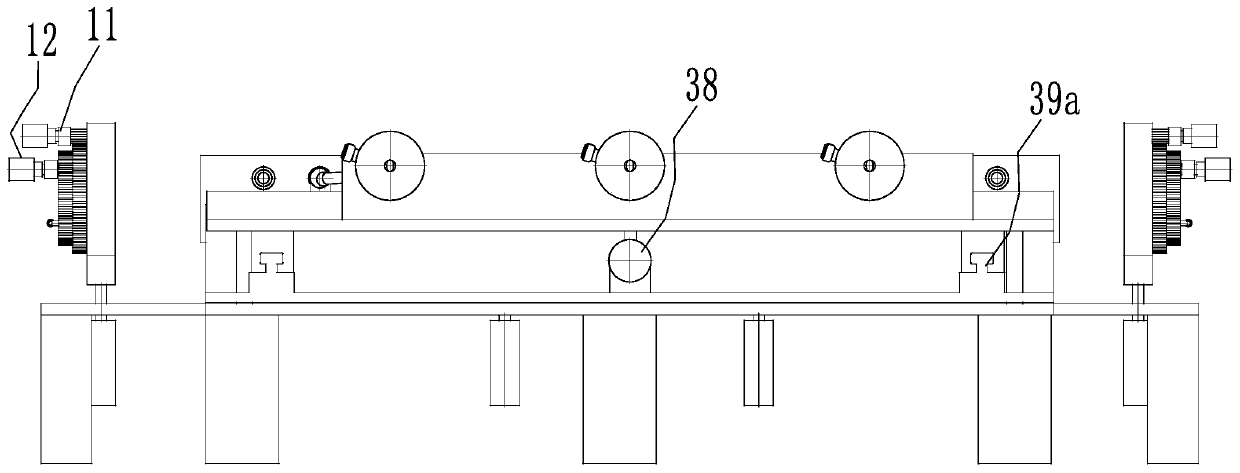

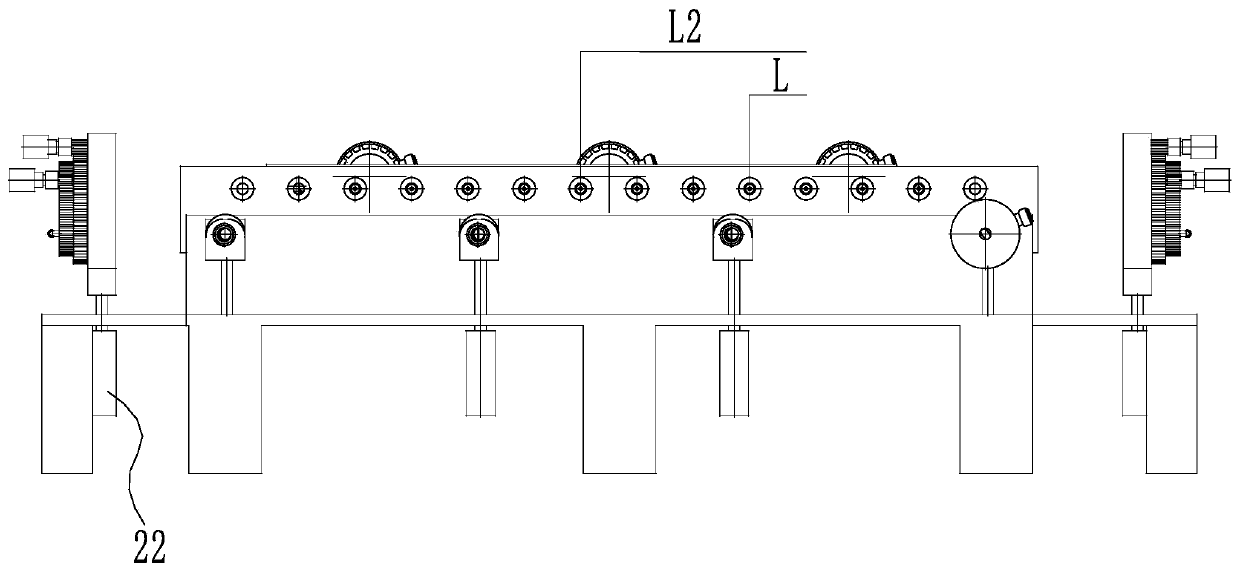

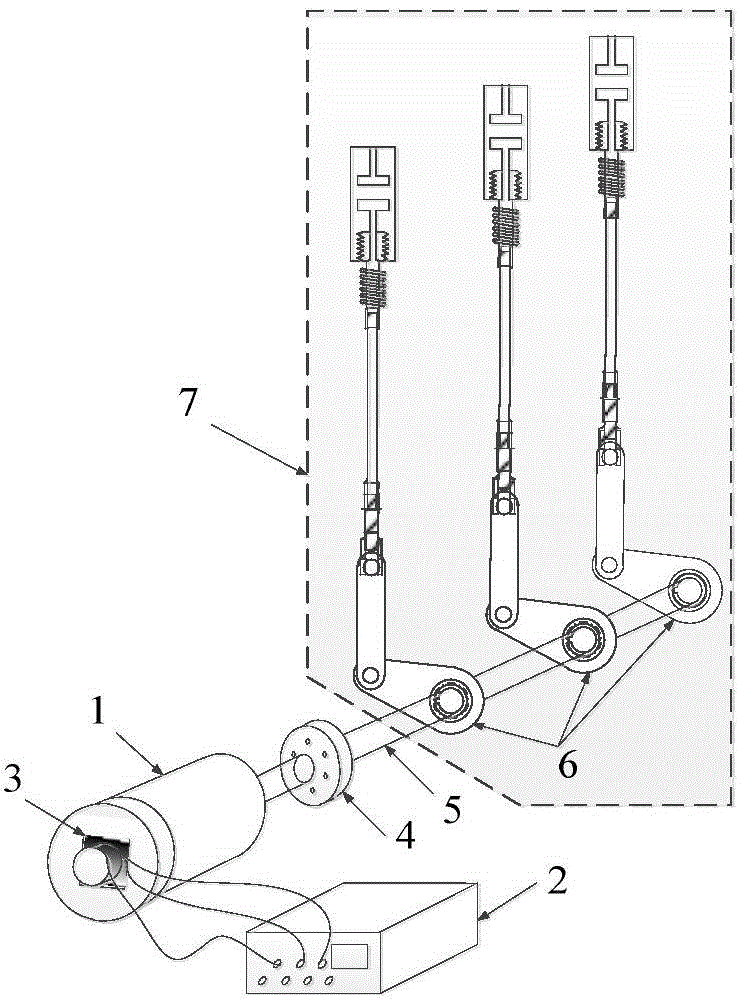

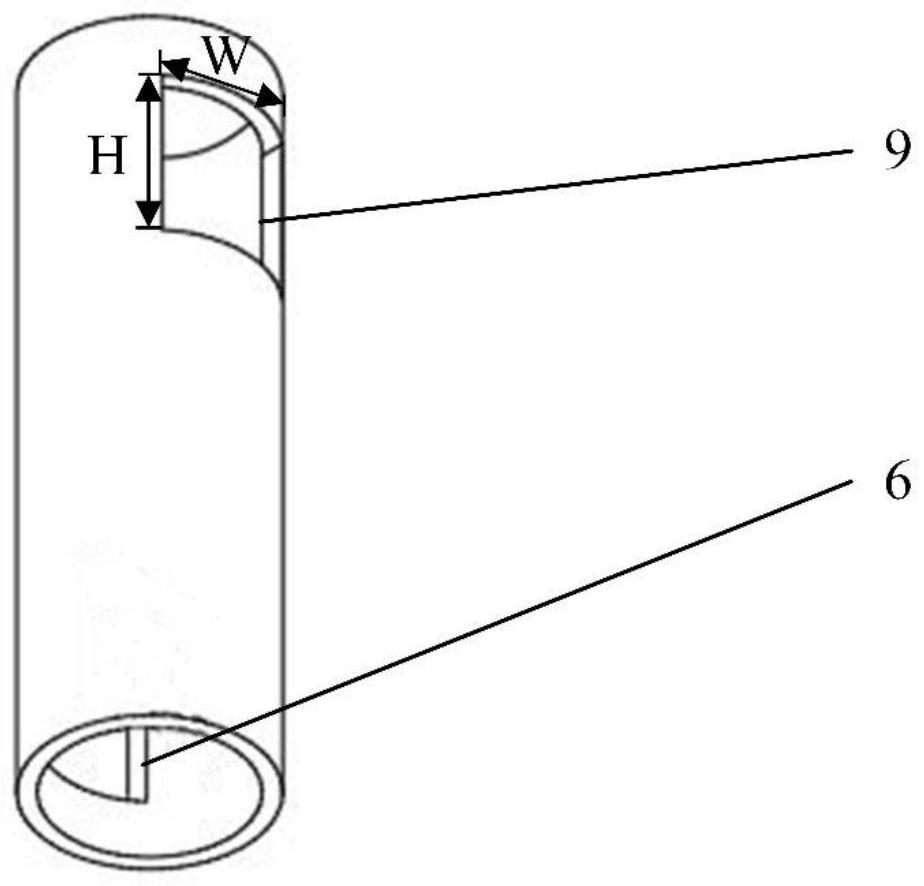

Efficient petroleum screen tube drilling machine and processing technology thereof

InactiveCN109759618AReduce manufacturing costIncrease productivityPositioning apparatusMetal working apparatusPetroleumDrilling machines

The invention provides an efficient petroleum screen tube drilling machine. The efficient petroleum screen tube drilling machine comprises a base frame, a drilling mechanism, a conveying mechanism anda clamping mechanism, wherein the drilling mechanism, the conveying mechanism and the clamping mechanism are arranged on the base frame, the drilling mechanism is used for drilling holes of a petroleum screen tube, the conveying mechanism is used for feeding the petroleum screen tube, the clamping mechanism is used for fixing the petroleum screen tube to be machined, the drilling mechanism comprises three motors, and the motors are in transmission connection with eleven drill bits through a gearbox. The invention further provides a processing technology of the efficient petroleum screen tubedrilling machine. The high-efficiency petroleum screen pipe drilling machine has the beneficial effects that the three motors are used for driving the eleven drill bits, so that the mode that one drill bit is driven by a motor is changed, the production cost is reduced, and meanwhile the production efficiency is greatly improved.

Owner:PANJIN LIAOHE OIL FIELD JINHUAN IND CO LTD

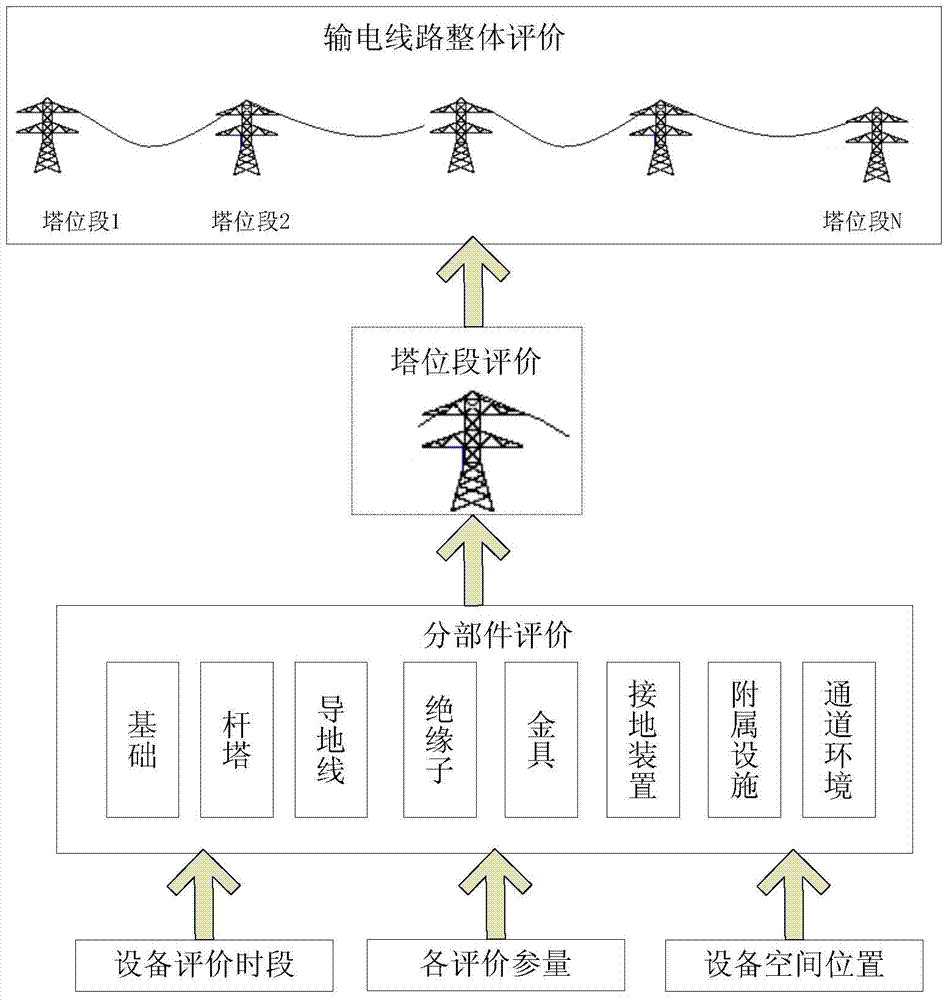

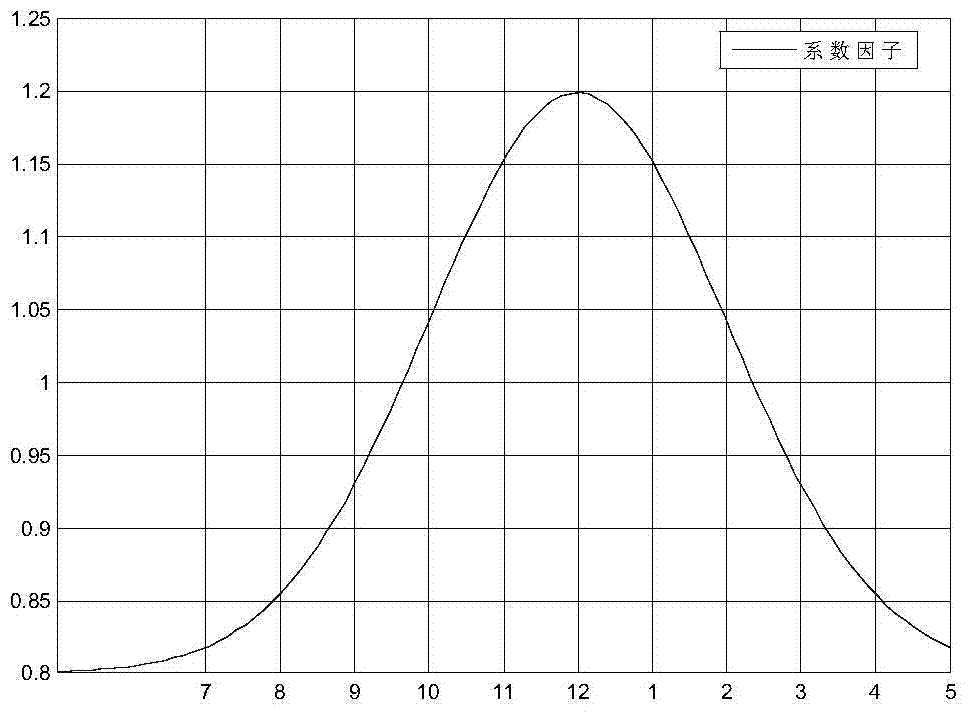

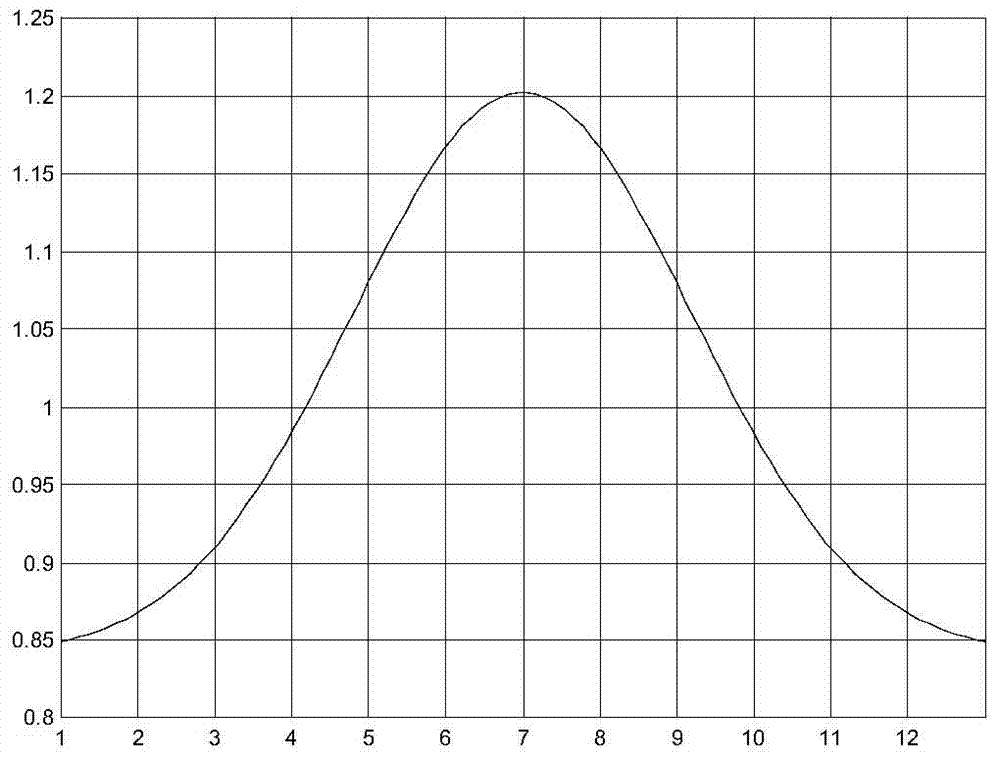

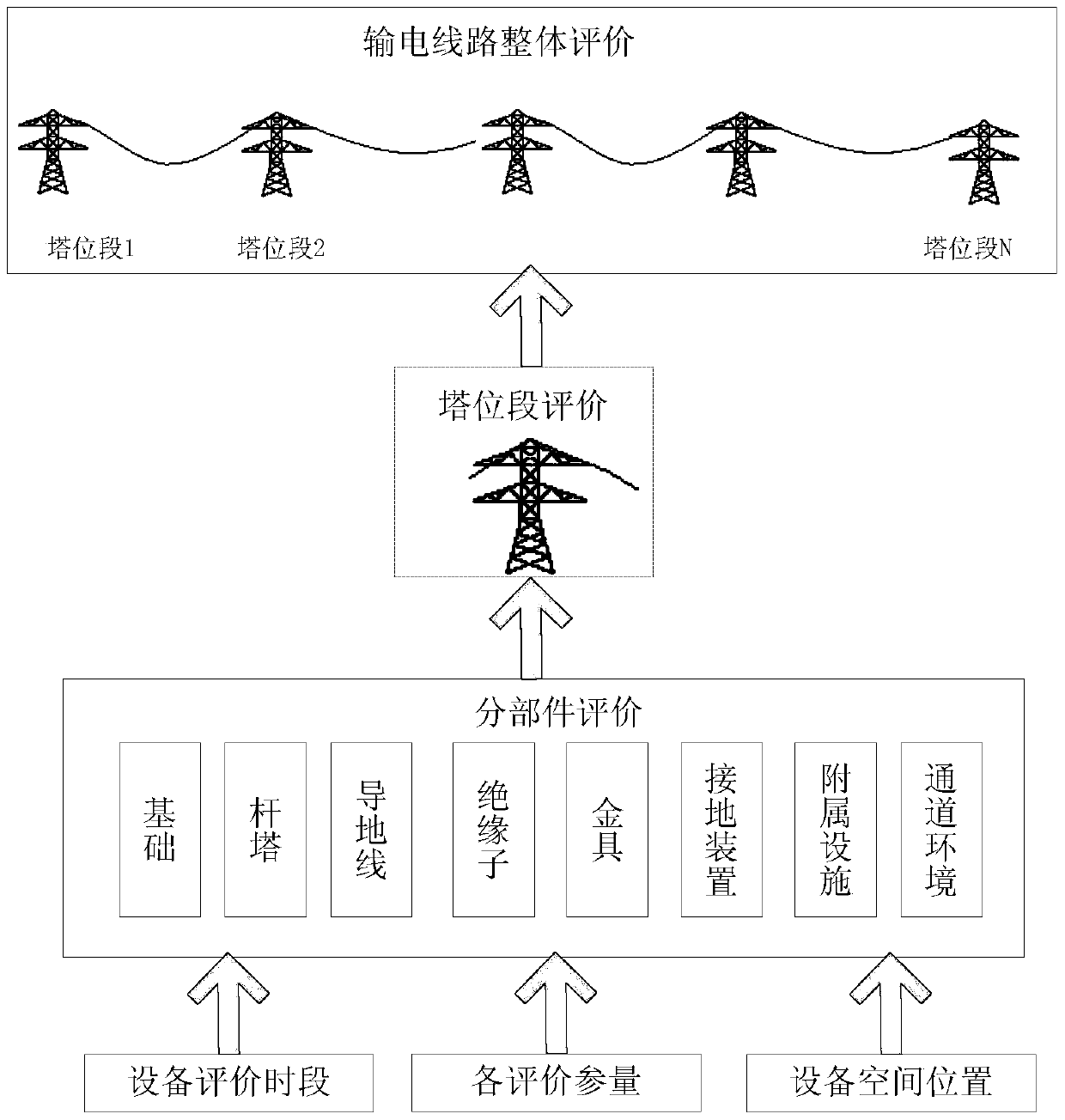

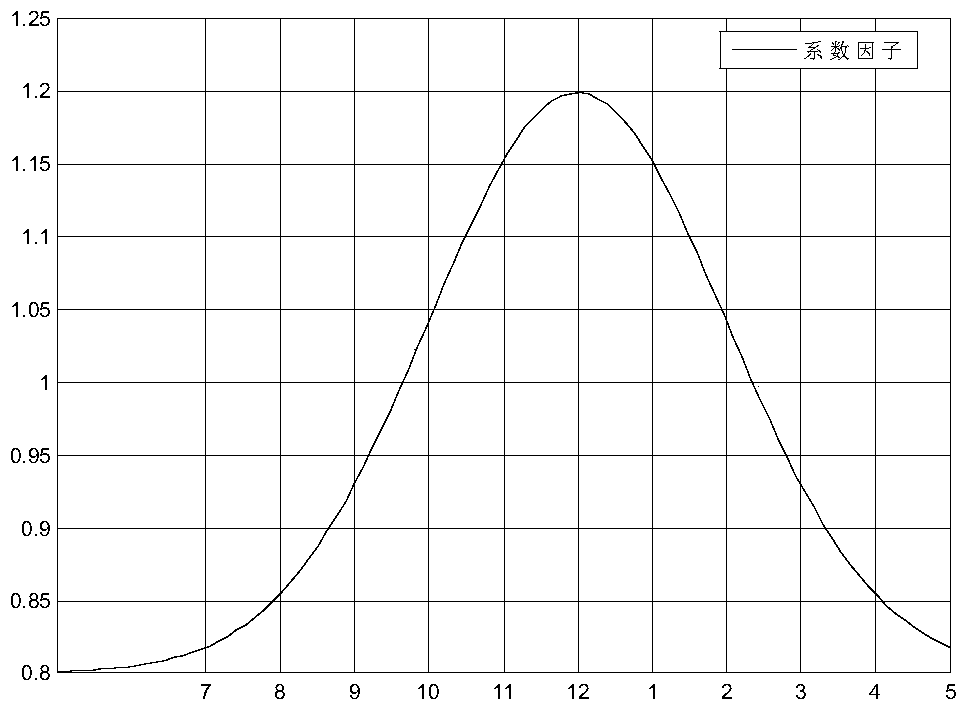

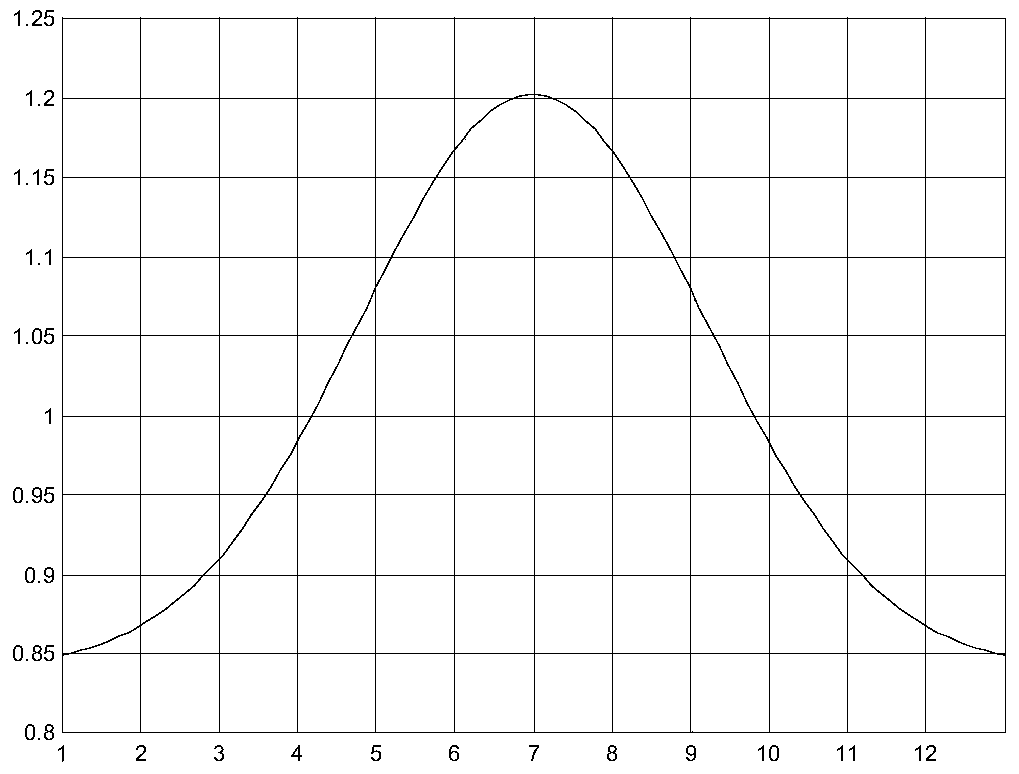

Method for assessing state of multi-dimensional power transmission equipment

ActiveCN104732058AGuaranteed uptimeImprove the level of intelligent operationSpecial data processing applicationsAssessment methodsMultilayered architecture

The invention provides a method for assessing the state of multi-dimensional power transmission equipment. The method includes the steps that firstly, a power transmission equipment state assessment model of a multi-layer structure is established and a special assessment period and a special line section are established; then, an accumulative mark reducing method serves as a basic marking method for all parameters in the assessment model, and in combination with the assessment period and an assessment section, actual weights and actual mark reducing values of all the parameters are given out; finally, according to parameter marks, the marks of all components, a tower section and the whole of the power transmission equipment are sequentially calculated, and the overall state of the power transmission equipment is comprehensively assessed in combination with the two dimensions of the assessment period and the assessment section. By the adoption of the method, information of three dimensions of line mark acquisition, time and space is fused, the method for assessing the state is comprehensive and expandable, and a final multi-dimensional assessment result is close to the true operation state of the power transmission equipment.

Owner:SHANGHAI JIAO TONG UNIV

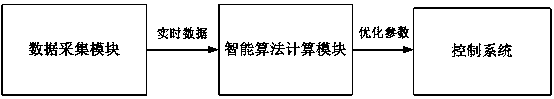

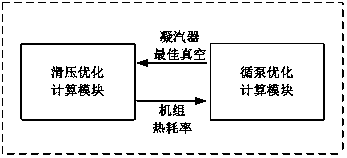

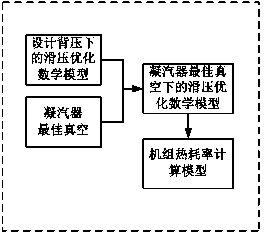

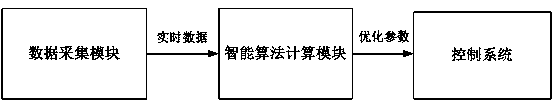

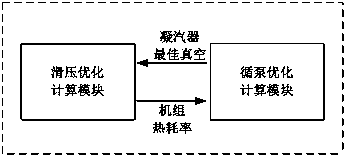

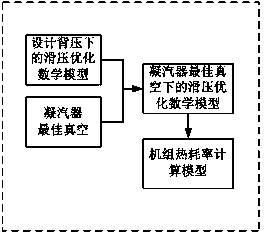

Intelligent economic operation system of steam turbine generator unit

ActiveCN108412558AImprove the level of intelligent operationAchieving simultaneous optimization runsSafety/regulatory devicesSteam engine plantsAuto regulationSteam pressure

The invention relates to an intelligent economic operation system of a steam turbine generator unit. The intelligent economic operation system comprises a data acquisition module, an intelligent algorithm computation module and a control module, wherein the data acquisition module is connected with the intelligent algorithm computation module, the intelligent algorithm computation module is connected with the control module, the control module is connected with a unit DCS control system and a unit coordinated control system, the data acquisition module is used for collecting real-time operating data of the DCS system of the generator unit and transmitting to the intelligent algorithm computation module, the intelligent algorithm computation module is used for calculating the current unit load, the optimal main steam pressure of a steam turbine at the temperature of circulating water and the optimal variable frequency of a water circulating pump by virtue of a sliding pressure optimization calculation module and a water circulating pump optimization calculation module, the optimal main steam pressure value and the optimal variable frequency value of the water circulating pump are transmitted to the unit DCS control system and the unit coordinated control system by virtue of the control system module, the unit is automatically adjusted to operate in a real-time optimization mode,and the intelligent economic operation of the steam turbine generator unit is realized.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

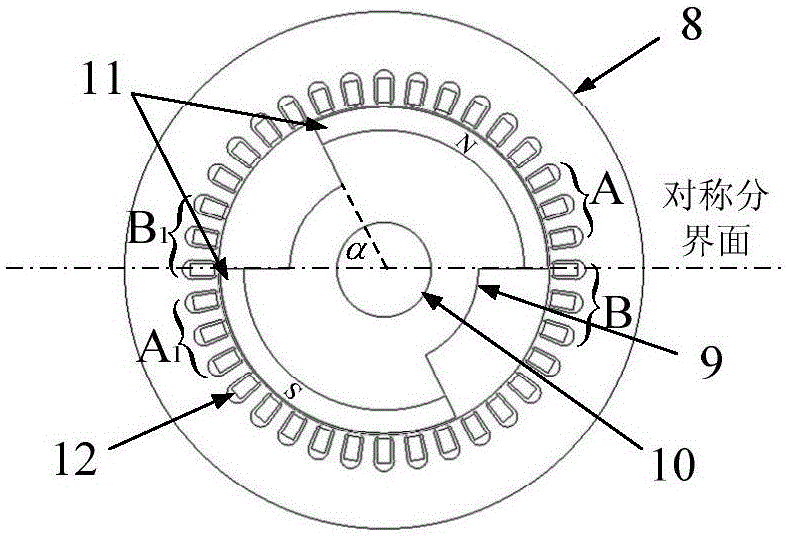

High-voltage breaker permanent magnet salient pole motor operation mechanism and control method

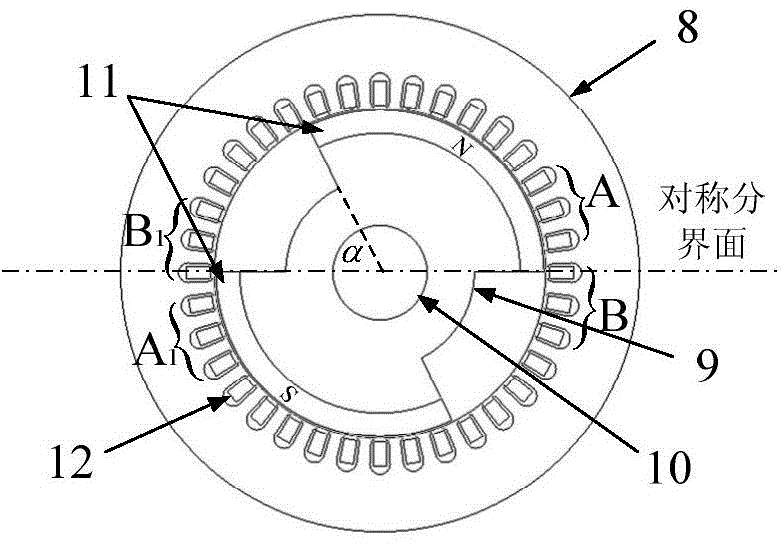

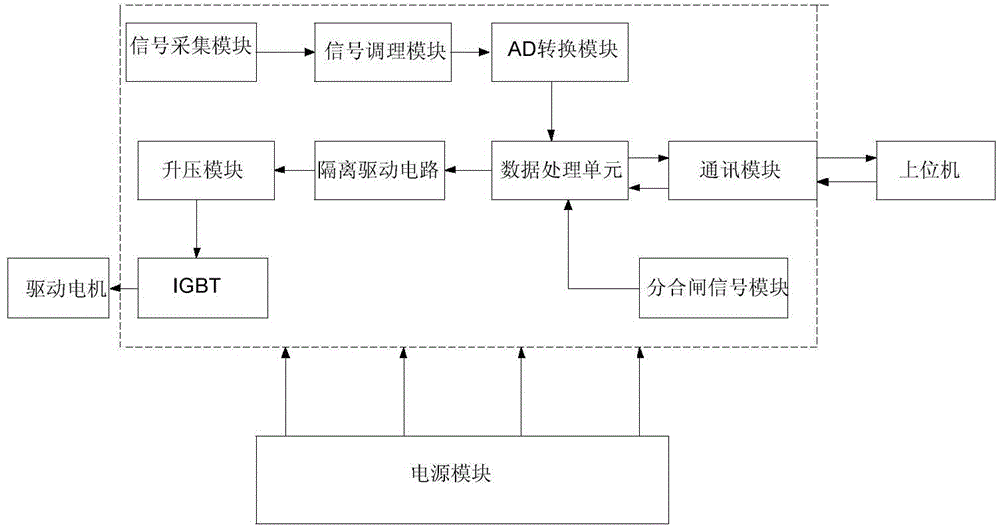

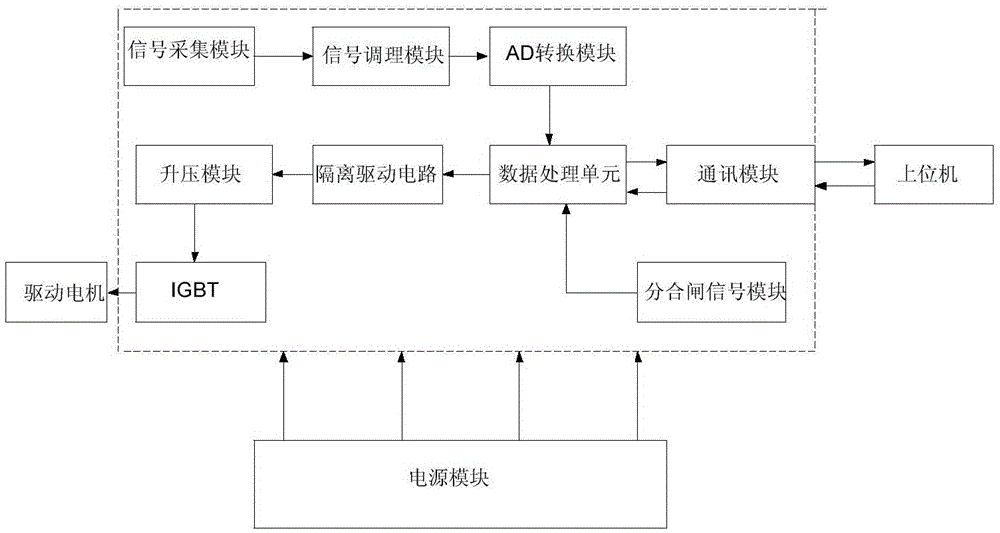

ActiveCN103560039AImprove the level of intelligent operationFew partsAC motor controlHigh-tension/heavy-dress switchesWeight coefficientEngineering

The invention provides a high-voltage breaker permanent magnet salient pole motor operation mechanism and a control method, and belongs to the filed of high-voltage switch equipment operation techniques. A drive motor of the operation mechanism drives a salient pole rotor to rotate by means of an electromagnetic torque produced by the drive motor itself and drives the switch-on and switch-off operations of a breaker. Currents are exerted in a single-phase armature winding, a magnetic field produced by a permanent magnet drives the salient pole rotor to rotate under the action of the electromagnetic force. According to the control method, firstly, a charging capacitor bank of the drive motor is charged, a speed weight coefficient and a current weight coefficient are set, and according to the collected armature current and rotation speed signals of the drive motor, the duty ratio and the frequency of a PWM signal is adjusted by means of a weight fuzzy PID algorithm. The drive motor does not need a phase change phase of a traditional permanent magnetic brushless direct-current motor within a work angle, energy consumption of the drive motor is reduced, efficiency of the drive motor can be obviously improved on the working condition that the high-voltage breaker works for a short time period, the non-equilibrium state process of motor phase change is avoided, and the control effect when the drive motor works for a short time period can be obviously improved.

Owner:SHENYANG POLYTECHNIC UNIV

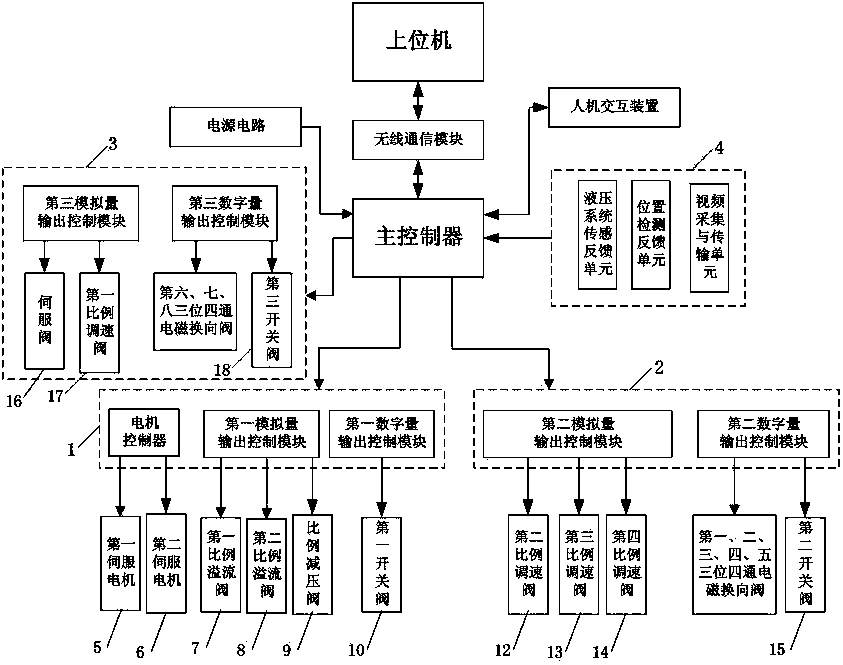

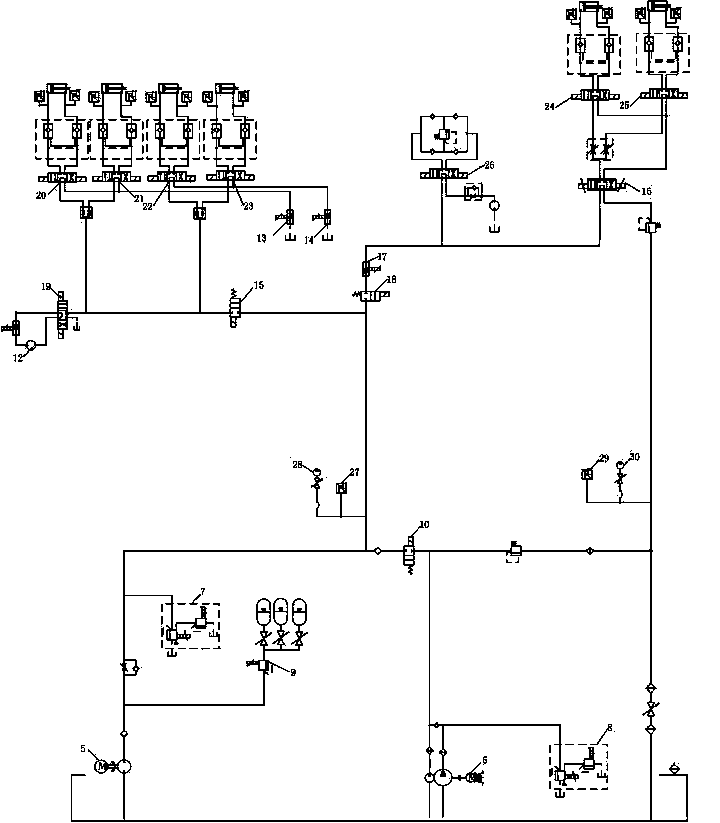

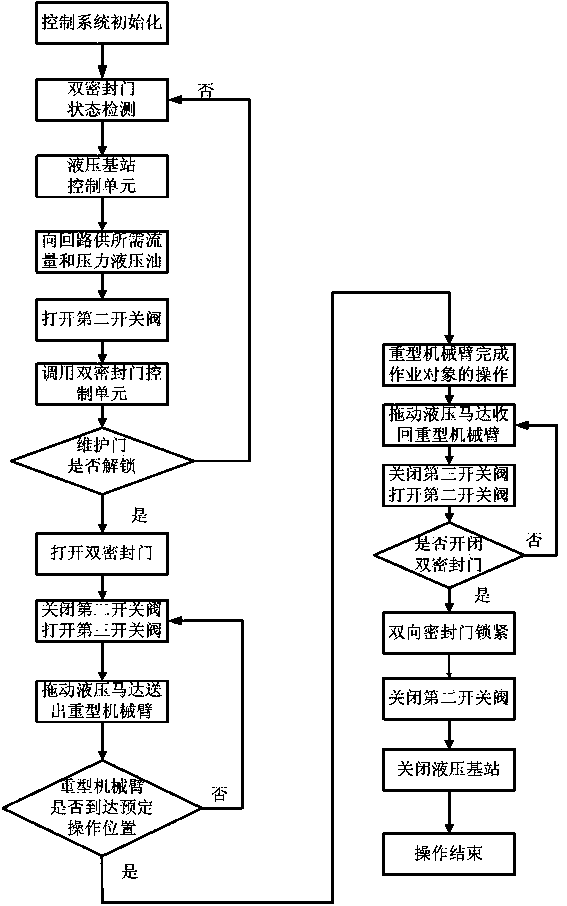

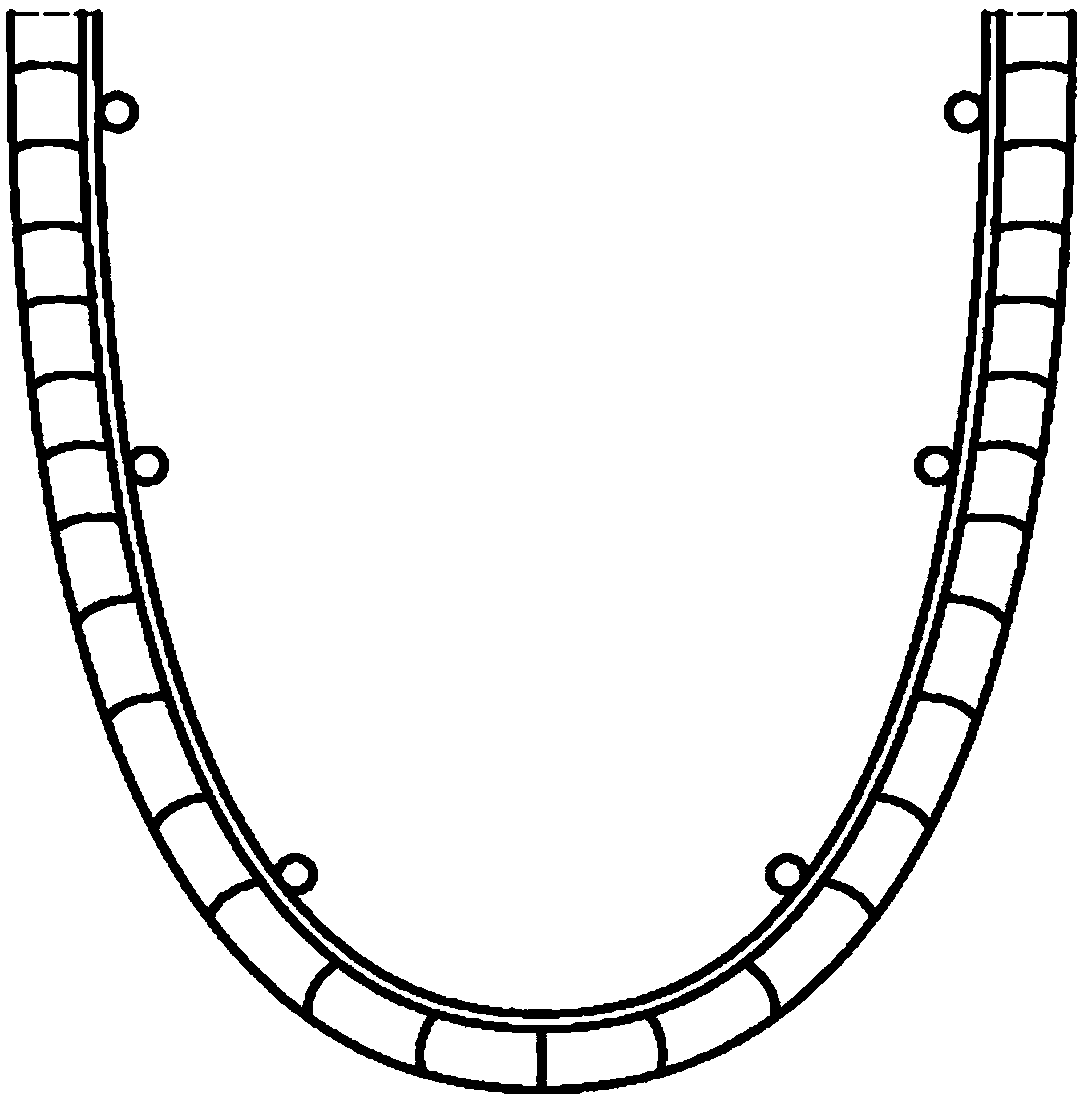

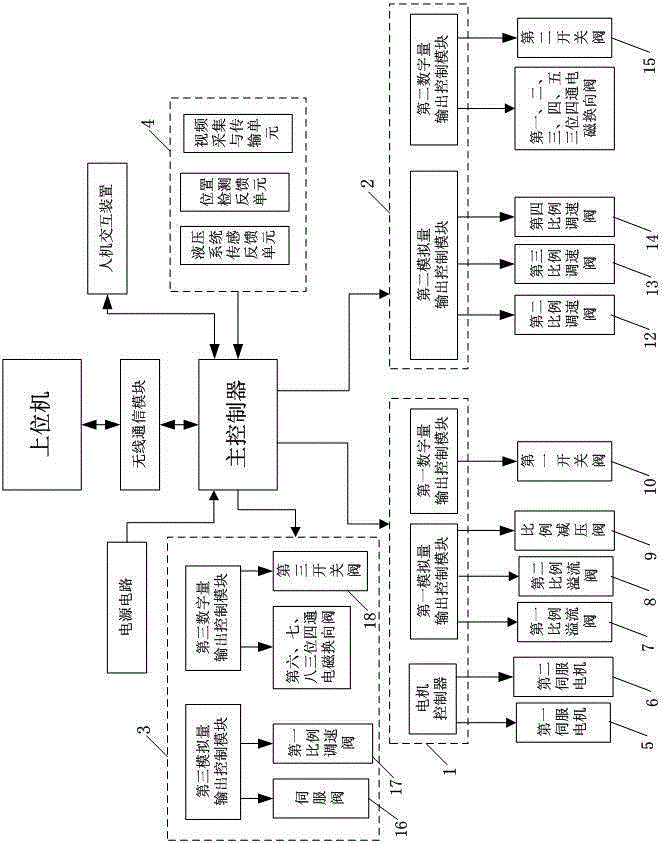

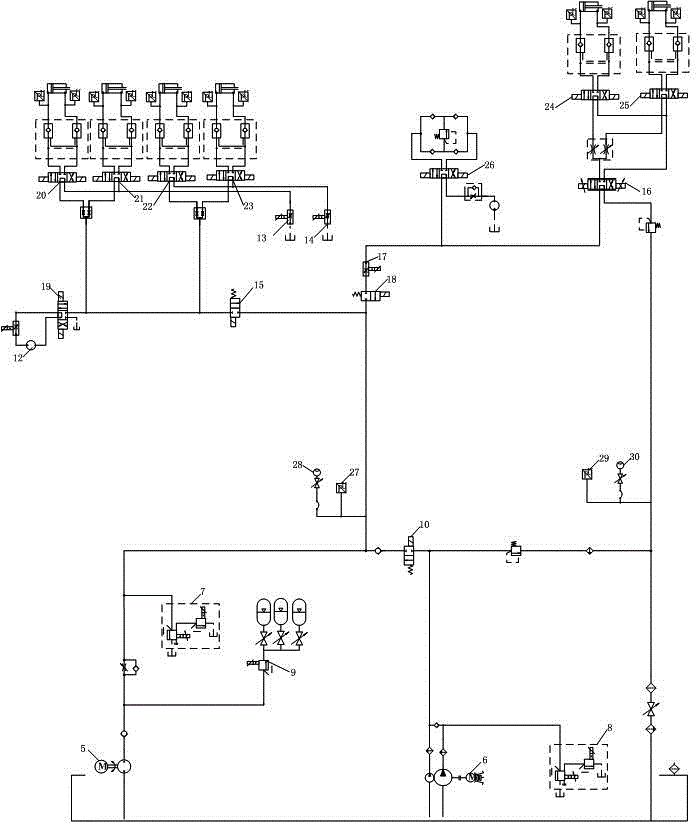

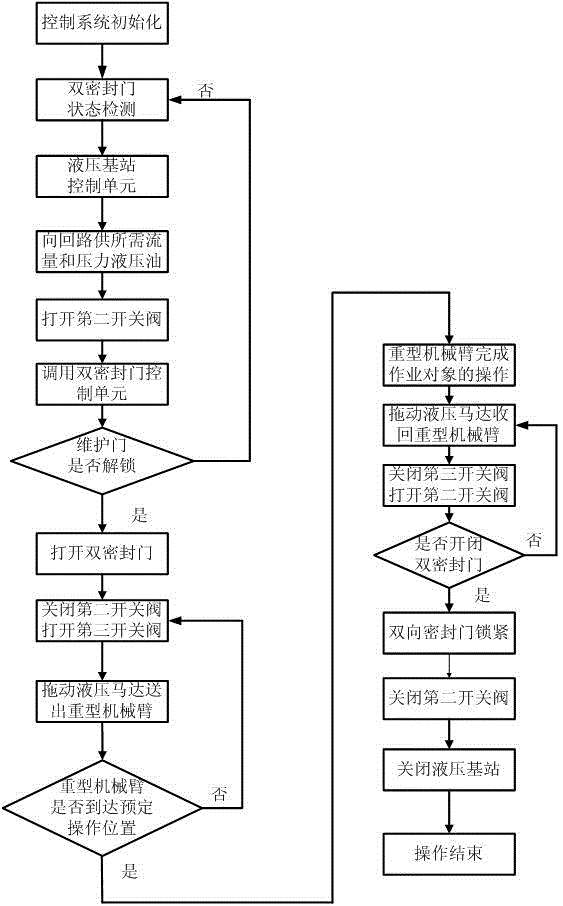

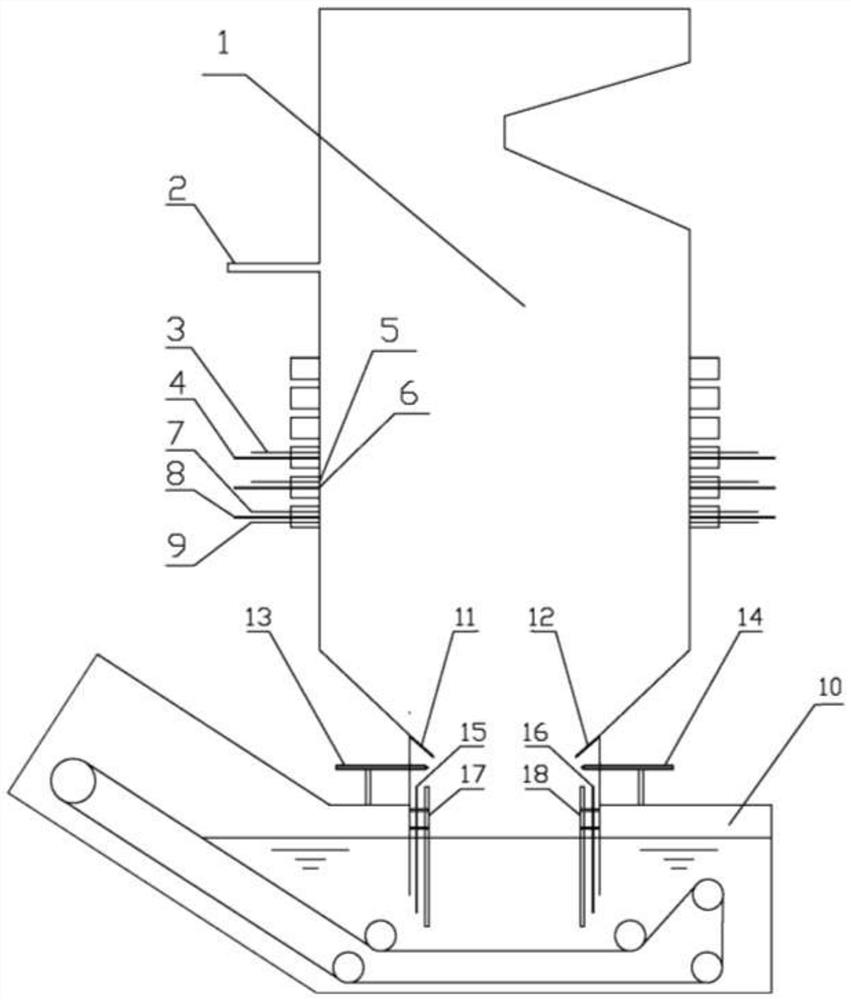

Part transport truck compartment control system applied to nuclear fusion device and control method thereof

InactiveCN103640531AGuaranteed teleoperationImprove the level of intelligent operationVehicles with cranesElectric/fluid circuitWork taskNuclear fusion

The invention relates to a part transport truck compartment control system applied to a nuclear fusion device. The part transport truck compartment control system applied to the nuclear fusion device comprises a main controller. The input end of the main controller is connected with the output end of a feedback detection unit and the output end of the main controller is connected with the input ends of a hydraulic base station control unit, a bidirectional sealing door control unit and a dragging mechanism control unit. The input and output end of the main controller is communicated with an upper computer through a wireless communication module and connected with the input and output end of a man-machine interaction device. The invention further discloses a control method of the part transport truck compartment control system applied to the nuclear fusion device. By the adoption of the part transport truck compartment control system applied to the nuclear fusion device and the method of the part transport truck compartment control system applied to the nuclear fusion device, stepped voltage regulation and flow change control can be achieved, logic sequence operation can be performed according to work tasks and wireless communication with the upper computer is carried out in real time. Remote operation of a transport truck compartment system under the nuclear fusion environment is effectively ensured, operation smoothness and operation safety are ensured and the intelligence operation level of a part transport truck is effectively improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Cloud computing dynamic parameter acquisition platform

InactiveCN108888965AImprove the level of intelligent operationRealize targeted filteringTelevision system detailsCharacter and pattern recognitionRecreationOutput device

The invention relates to a cloud computing type parameter dynamic acquisition platform, comprising: an adequacy analysis device connected with a field power storage device, used for detecting the adequacy of the electric power currently stored by the field power storage device, so as to stop the electric power reception of the field power storage device to the outside when the adequacy exceeds a limited amount; and a cloud computing type parameter dynamic acquisition platform connected with the field power storage device. An energy receiving device arranged on the U-shaped skateboard recreation structure for receiving solar energy at the position of the U-shaped skateboard recreation structure and converting the solar energy at the position of the U-shaped skateboard recreation structure into electric energy; A multi-pattern statistic device is connected with the image output device for receiving the filtered image and performing a gender acquisition process on the filtered image basedon cloud computing. The invention improves the response ability of the field equipment.

Owner:王昆

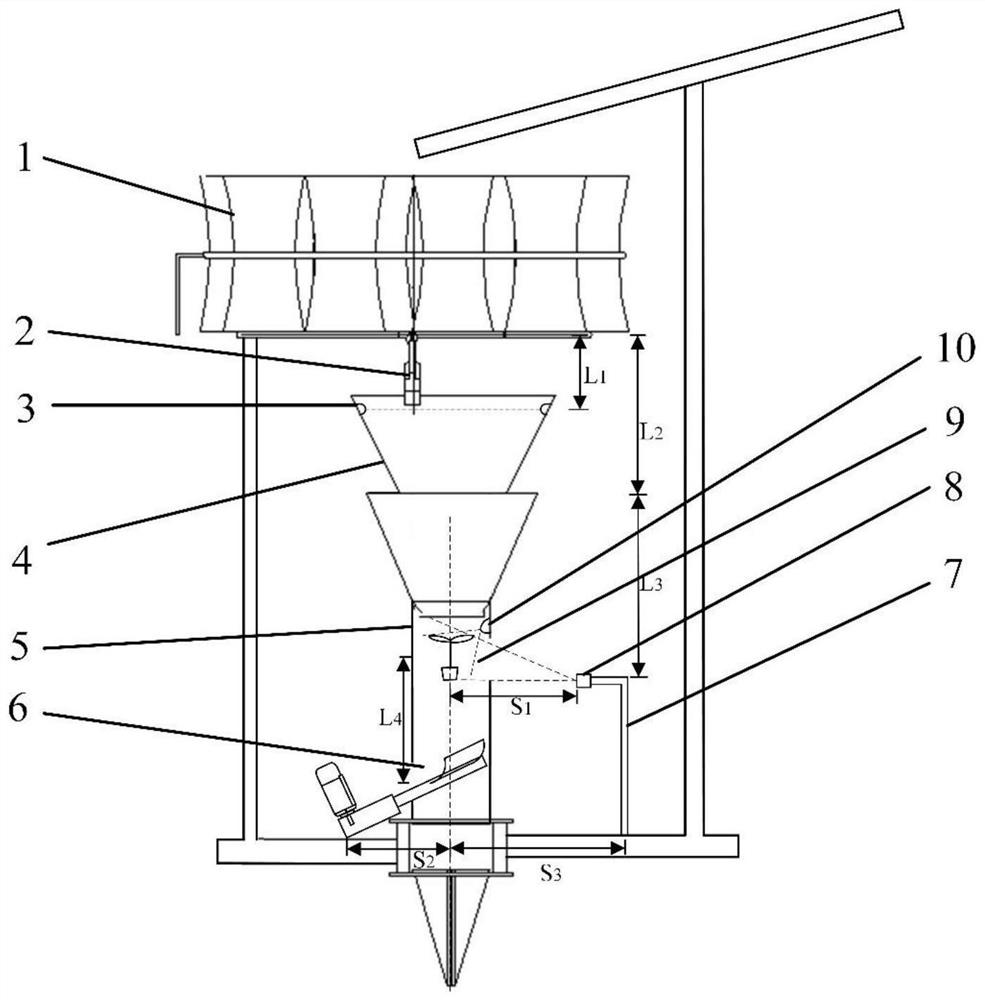

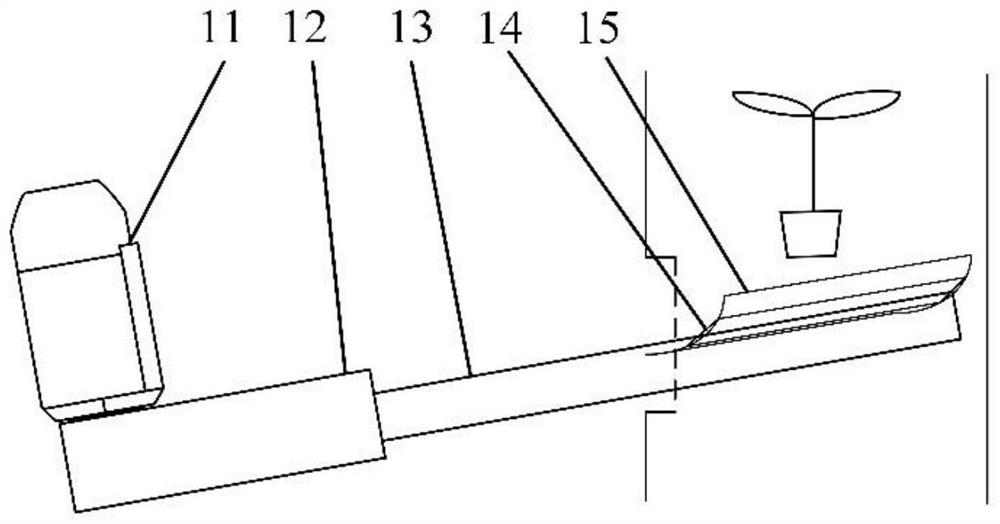

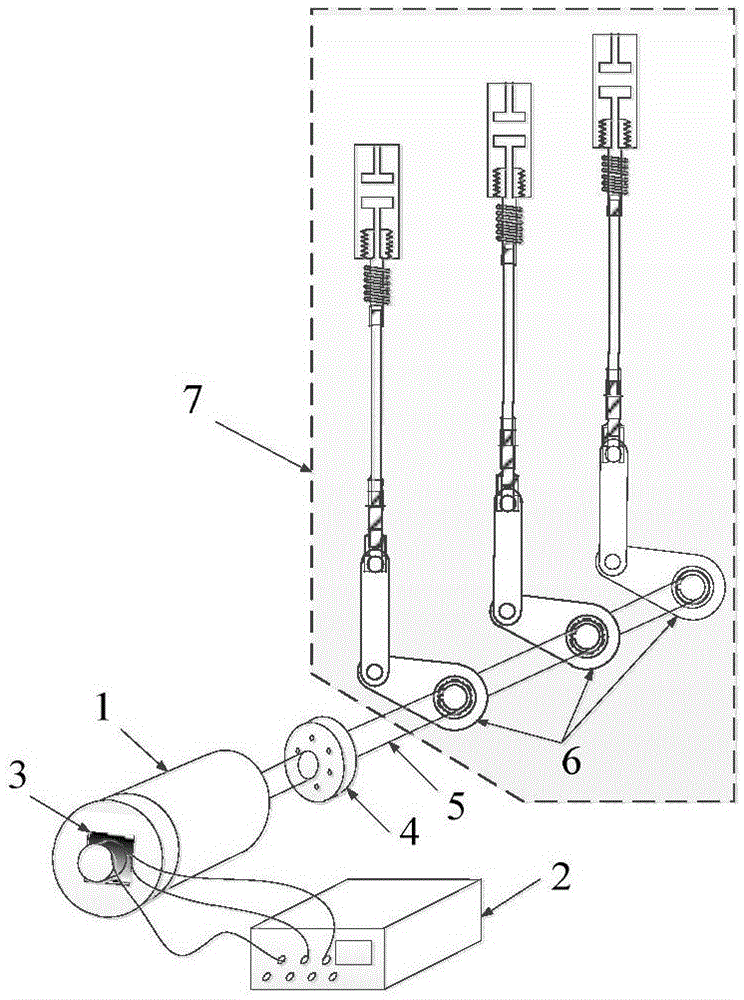

Pot seedling disease monitoring-seedling removing system and method for semi-automatic transplanter

PendingCN112464759AAccurate and Rapid DiagnosisAccurate and fast rejectionData processing applicationsEnsemble learningDisease monitoringAgricultural science

The invention provides a pot seedling disease monitoring and seedling removing system and method of a semi-automatic transplanter, and belongs to the field of agricultural robots. The pot seedling disease monitoring and seedling removing system comprises a pot seedling panoramic information head-up obtaining device and a light and simple retractable bad seedling removing device, and the pot seedling panoramic information head-up obtaining device is used for dynamically and reliably capturing panoramic information of falling pot seedlings; through layer-by-layer deep learning training of multi-part multi-disease complex characteristics, self-input and layer-by-layer comparison of pot seedling RGB images to a multi-layer classification linear image solidification template, accurate and rapiddiagnosis of diseased seedlings in the free falling process of pot seedlings is achieved, and therefore the intelligent operation level of the field semi-automatic transplanter is effectively improved.

Owner:JIANGSU UNIV

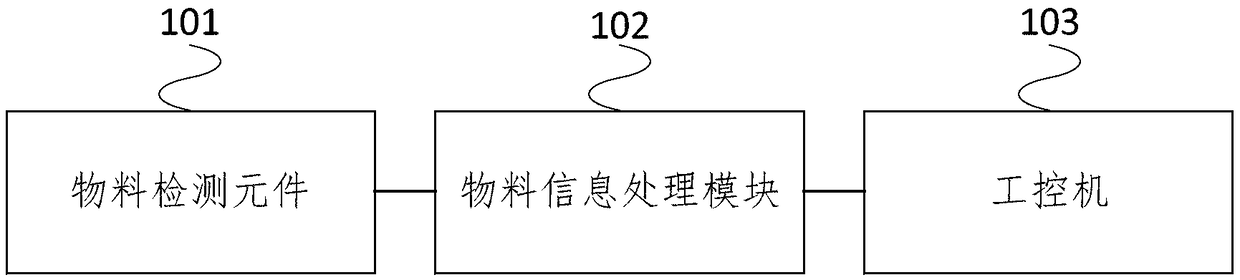

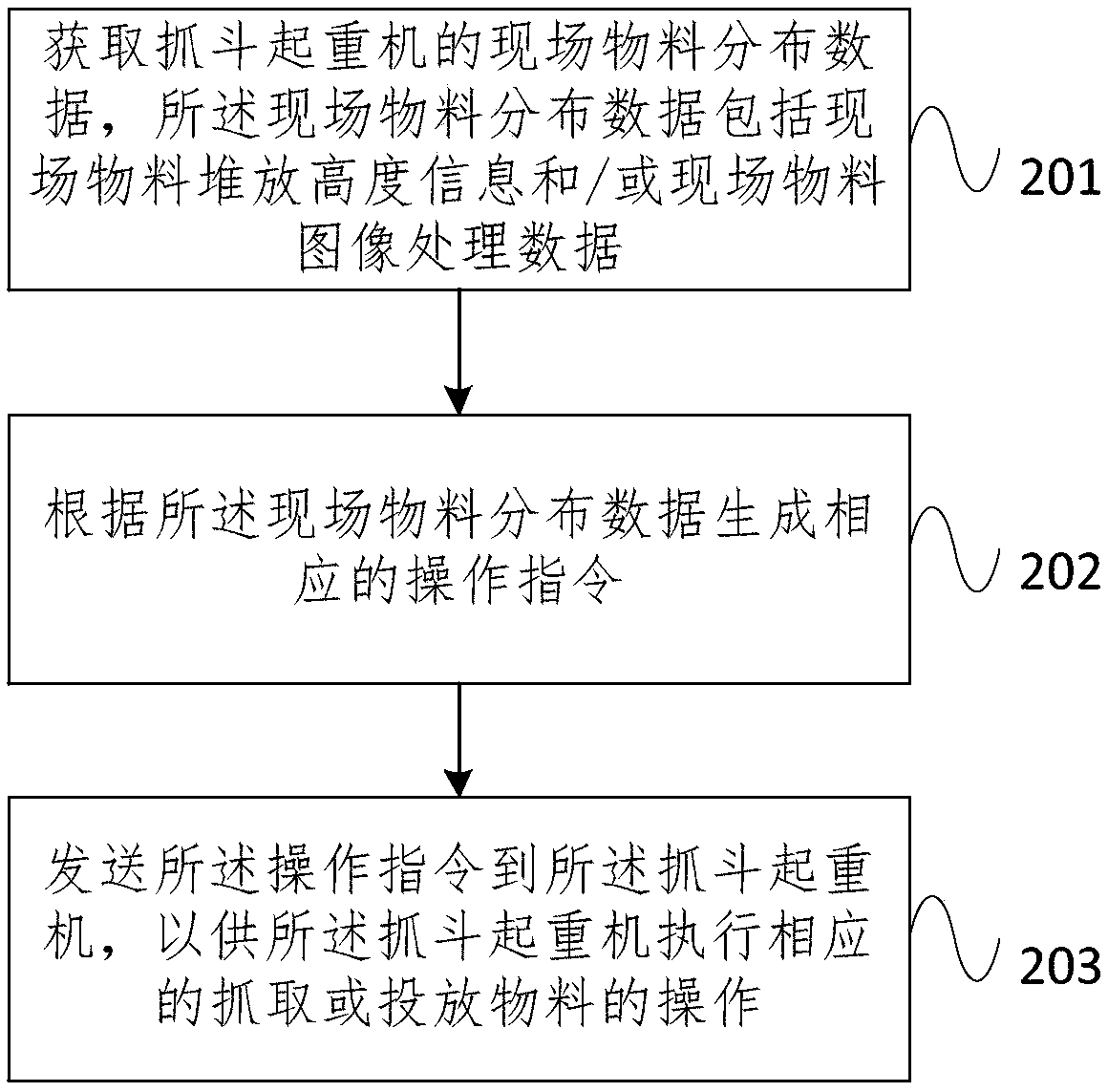

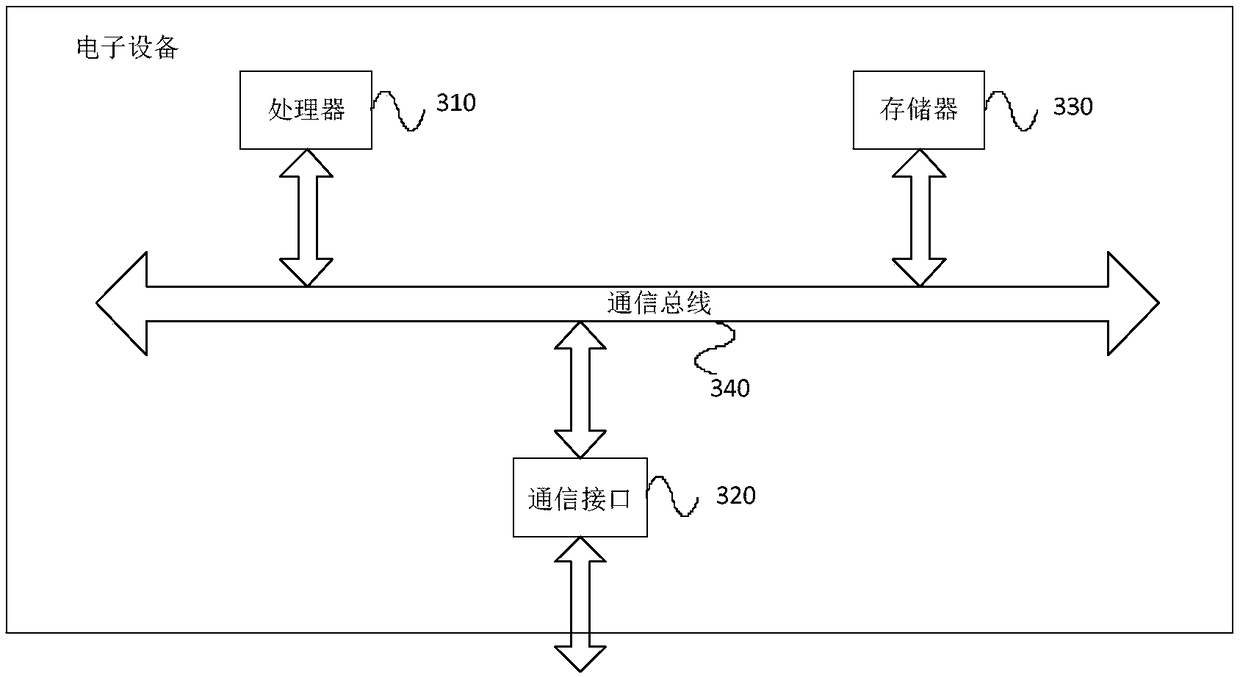

Grab bucket crane control system and method based on material detection

PendingCN109019336AImprove the level of intelligent operationThe grabbing position is accurateLoad-engaging elementsCranesManufacturing engineeringControl system

The embodiment of the invention provides a grab bucket crane control system and method based on material detection. The system comprises a material detection element, a material information processingmodule and an industrial control machine. The material detection element is used for collecting site material distribution data and sending the site material distribution data to the industrial control machine, the site material distribution data comprise site material stacking height information and / or site material image processing data, the material information processing module is used for processing the site material distribution data, uploaded to the industrial control machine, of the material detection element, and according to the site material image processing data, a corresponding operation instruction is generated; the material information processing module is arranged on the industrial control machine; the industrial control machine is used for sending an operation instructionto a grab bucket crane so as to allow the grab bucket crane to execute the corresponding material grabbing or putting operation. According to the system and method, through detection of the materialstacking distribution state, the accurate material grabbing or putting position is provided for the grab bucket crane, and the intelligent level of the grab bucket crane is improved.

Owner:BEIJING MATERIALS HANDLING TECH INST CO LTD

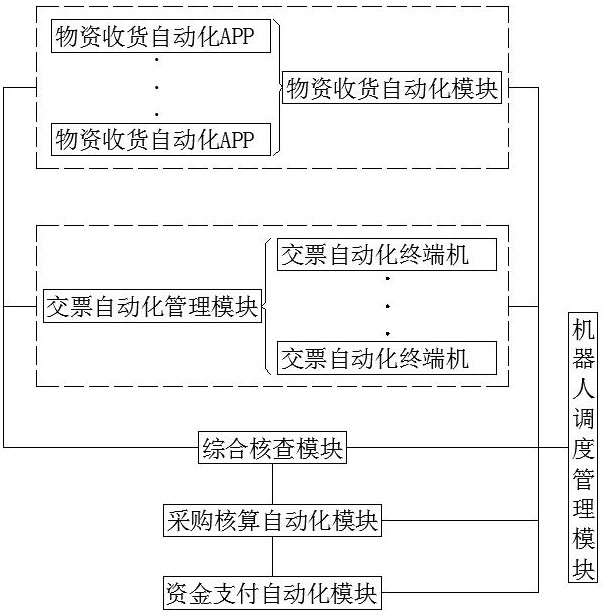

Material purchasing settlement management system based on financial robot

PendingCN111798220AProcessing speedImprove efficiencyFinanceCharacter and pattern recognitionPaymentPurchasing

The invention discloses a material purchasing settlement management system based on a financial robot. The system comprises a robot scheduling management module, a material receiving automation module, a bill submission automation management module, a comprehensive checking module, a purchasing accounting automation module and a fund payment automation module. The robot scheduling management module schedules a financial robot to participate in and execute the work of the material receiving automation module, the bill submission automation management module, the comprehensive checking module, the purchasing accounting automation module and the fund payment automation module. The work of receiving, warehousing and acceptance check, bill submission, bill auditing, financial auditing and fundpayment can be efficiently and accurately carried out, the processing efficiency and accuracy of the purchasing settlement process are greatly improved, and a large amount of manpower is saved.

Owner:SICHUAN ZHONGDIAN AOSTAR INFORMATION TECHNOLOGIES CO LTD

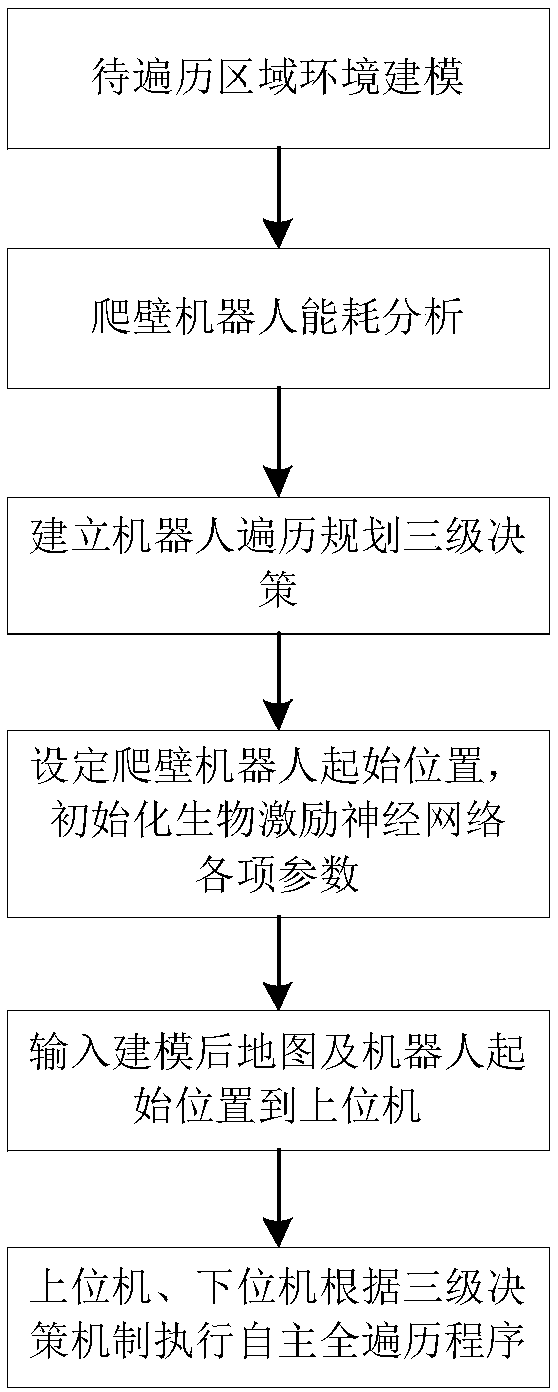

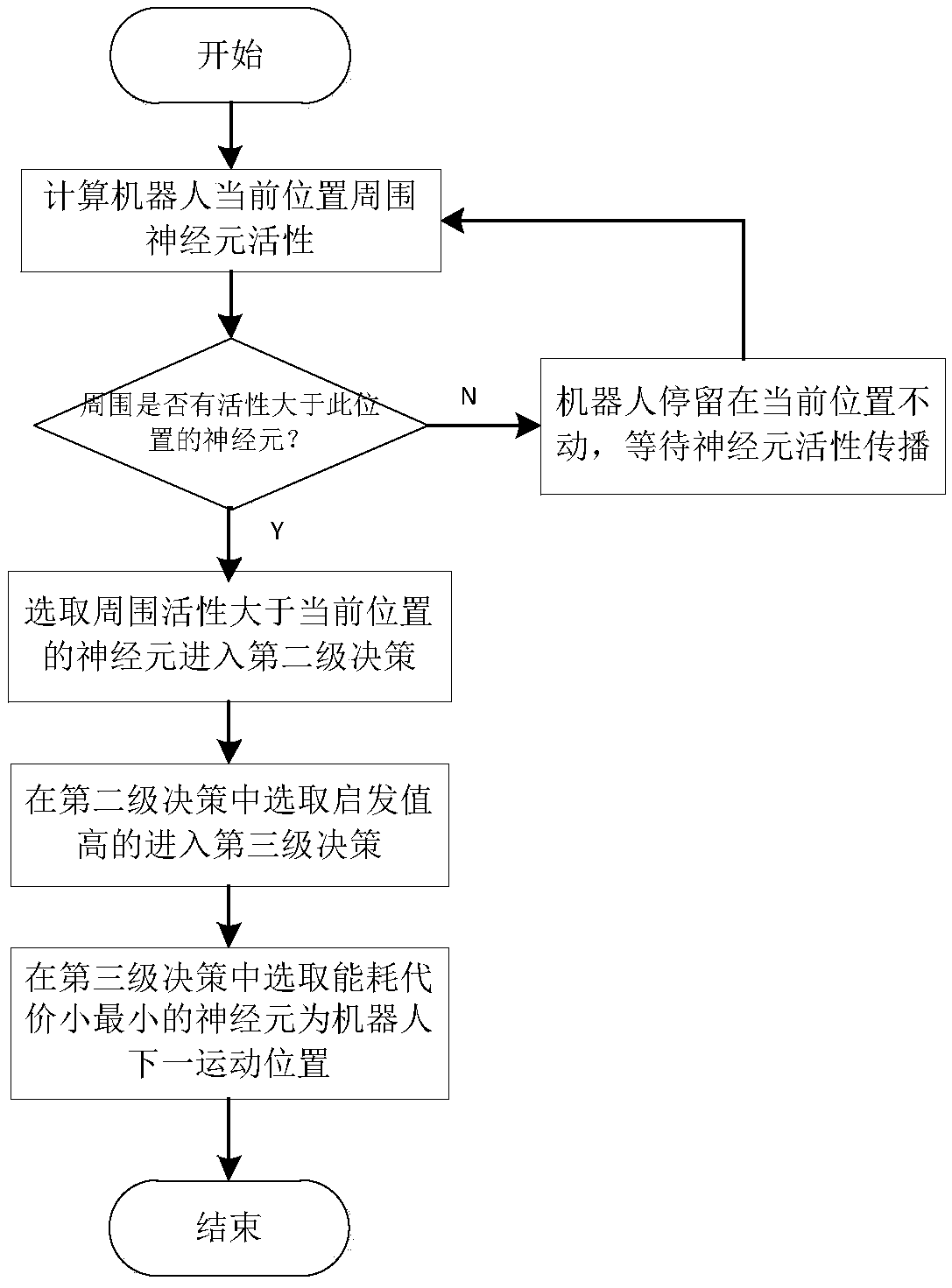

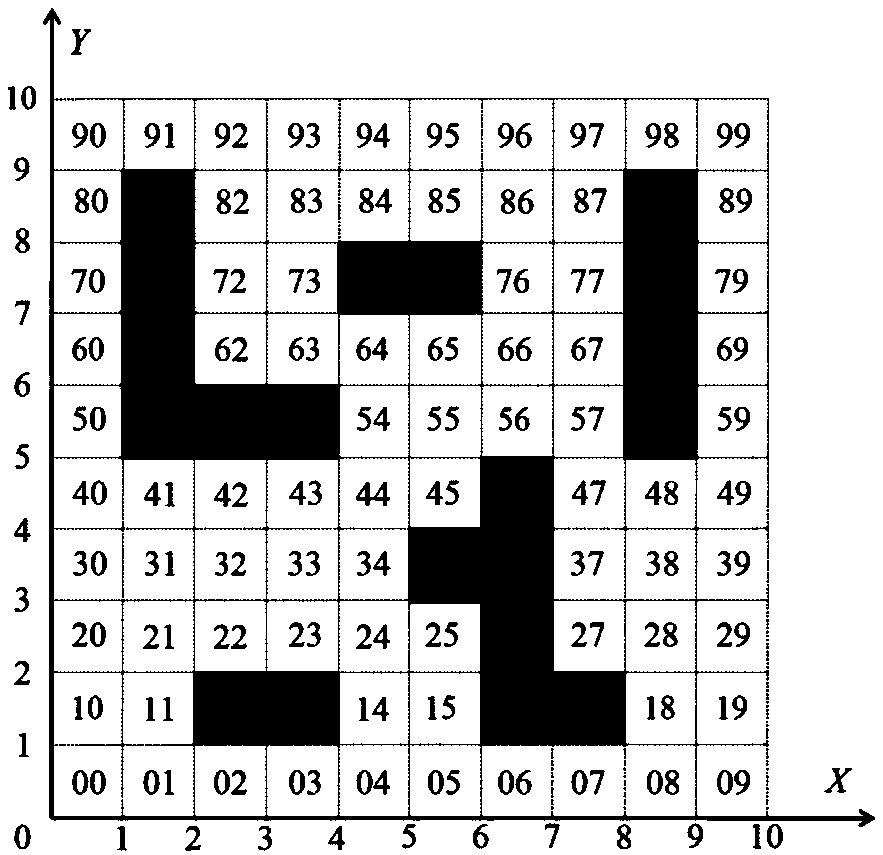

Autonomous full transversal wall-climbing robot

InactiveCN108639177AReduce energy consumptionReduce manpower consumptionPosition/course control in two dimensionsVehiclesSimulationPeripheral neuron

The invention relates to an autonomous full traversal wall-climbing robot. The autonomous full traversal wall-climbing robot relates to the method comprising the steps that an area to be detected of the wall-climbing robot is divided into a plurality of grids by using a grid method, and each grid is used as a neuron to obtain a biological excitation neural network map; the activity of neurons around the current position of a wall-climbing robot body is calculated; a neuron of which the activity is greater than that of the neurons at the current position is selected as the neuron to be selected; for each neuron to be selected, the heuristic value of peripheral neurons of each neuron to be selected to the each neuron to be selected is calculated; according to the model of motion energy consumption, the motion energy consumption of the robot body moving from the current position to the corresponding position of the neuron to be selected is calculated; and the selected neuron with the minimum motion energy consumption is selected as the next target position of the robot body. The autonomous full traversal wall-climbing robot can autonomously complete the full traversal task in a low energy consumption way.

Owner:南京赫曼机器人自动化有限公司

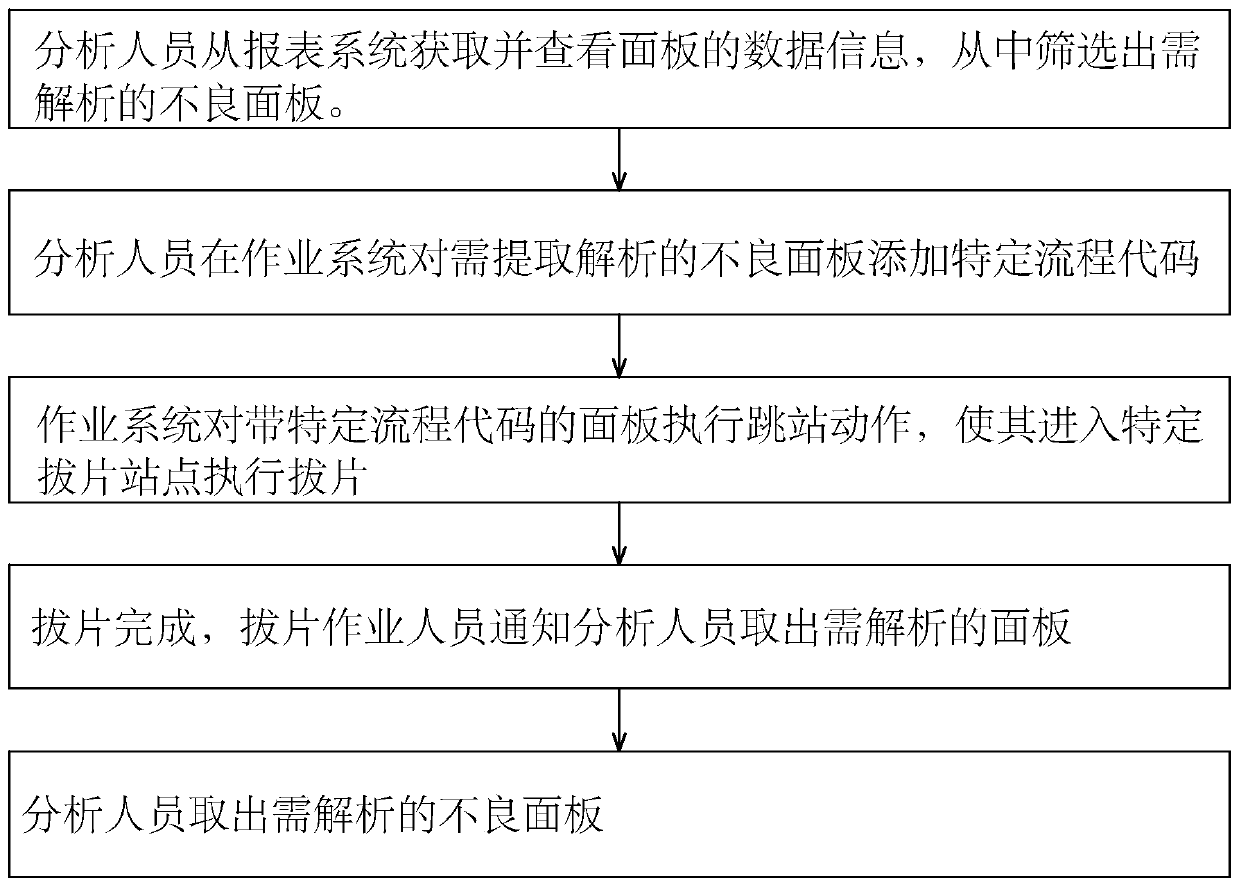

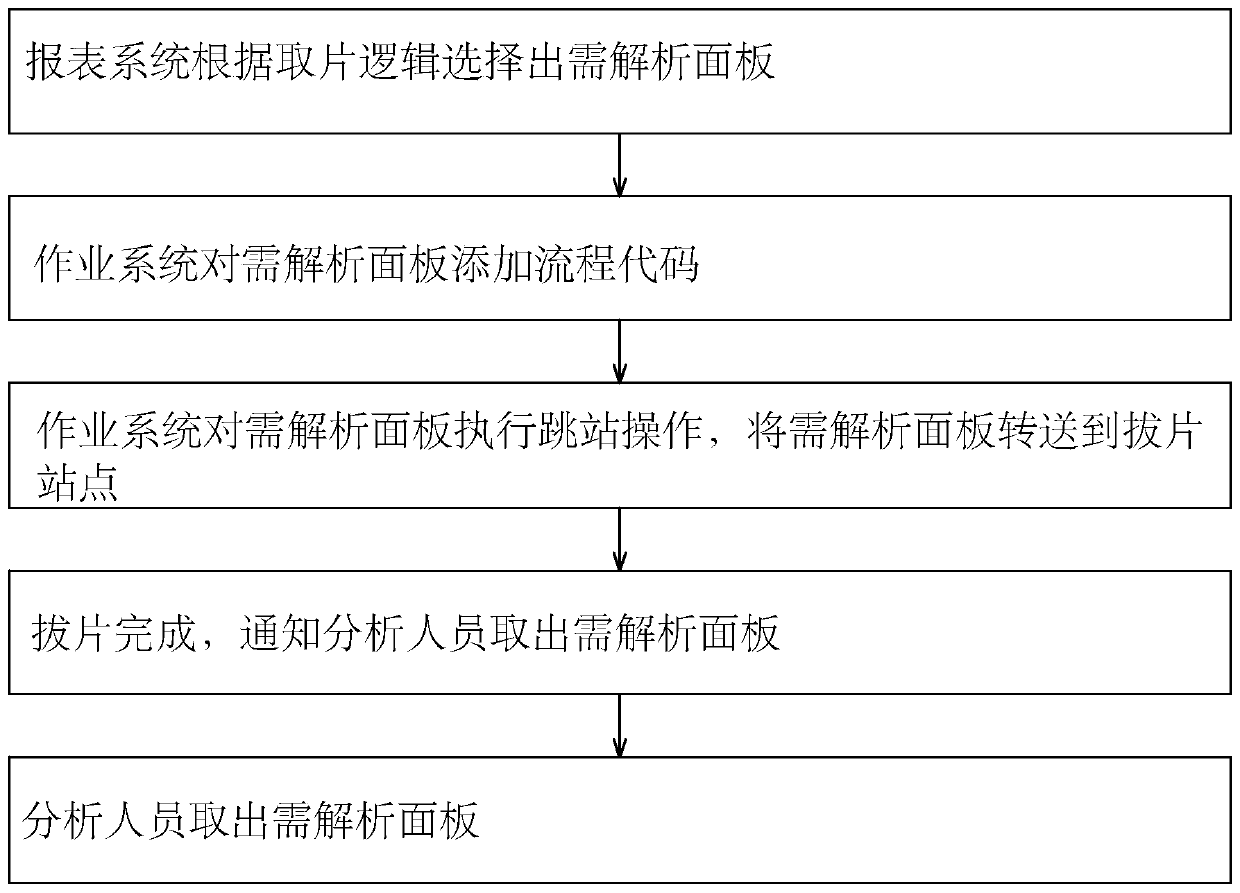

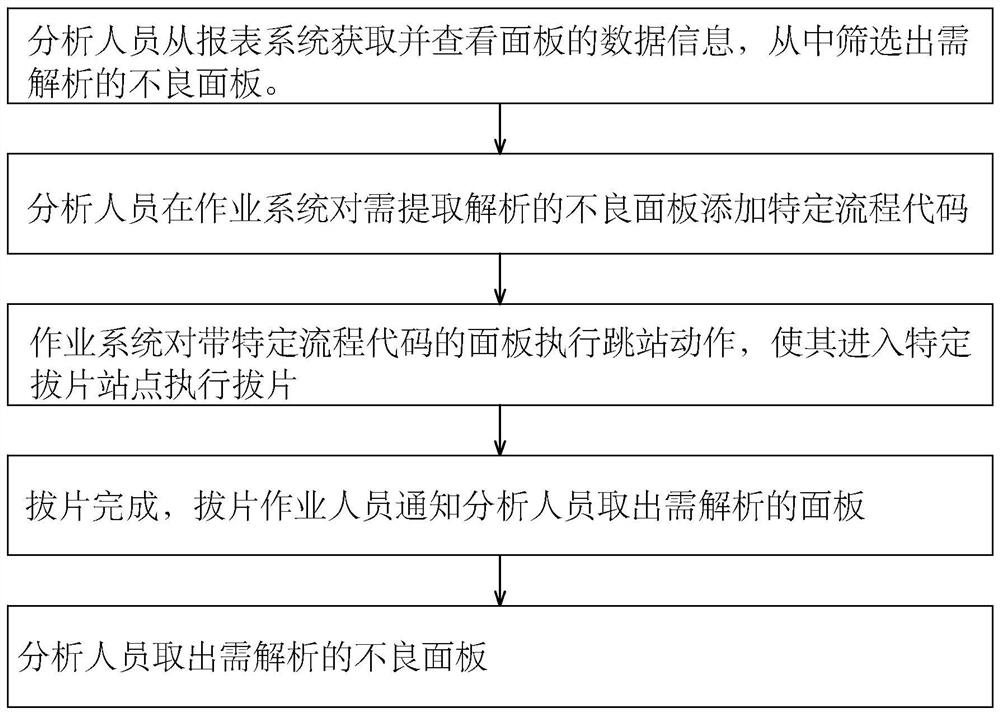

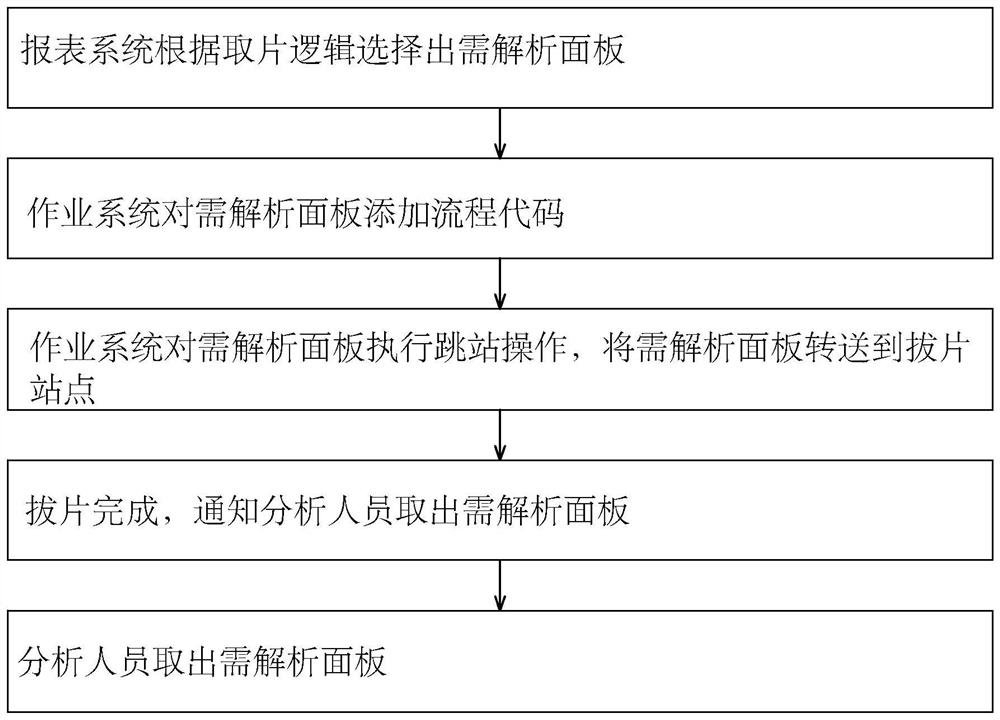

Panel withdrawing system and method for defect analysis

ActiveCN109946862AImprove automationImprove the level of intelligent operationStatic indicating devicesNon-linear opticsProduction lineData information

The invention relates to a panel withdrawing system and method for defect analysis. The panel withdrawing system for defect analysis comprises a report system and an operating system, wherein the report system collects and displays panel information on the production line, and the operation system performs designated operation on the flow direction of panels on the production line; a user inputs panel withdrawing logic to the report system, a logic development module is arranged in the report system, the report system selects to-be-analyzed panels by the logic development module according to the panel withdrawing logic, and data information of the to-be-analyzed panels is transmitted to the operating system, and the operating system adds a process code to the to-be-analyzed panels, performs station jumping operation on the to-be-analyzed panels and transfers the panels to a panel drawing station. Therefore, the system and the method have the advantages that the action of drawing analysis can be performed in time when the production line panels are abnormal, and the automatic and intelligent operation level of panel withdrawing for defect analysis is greatly increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

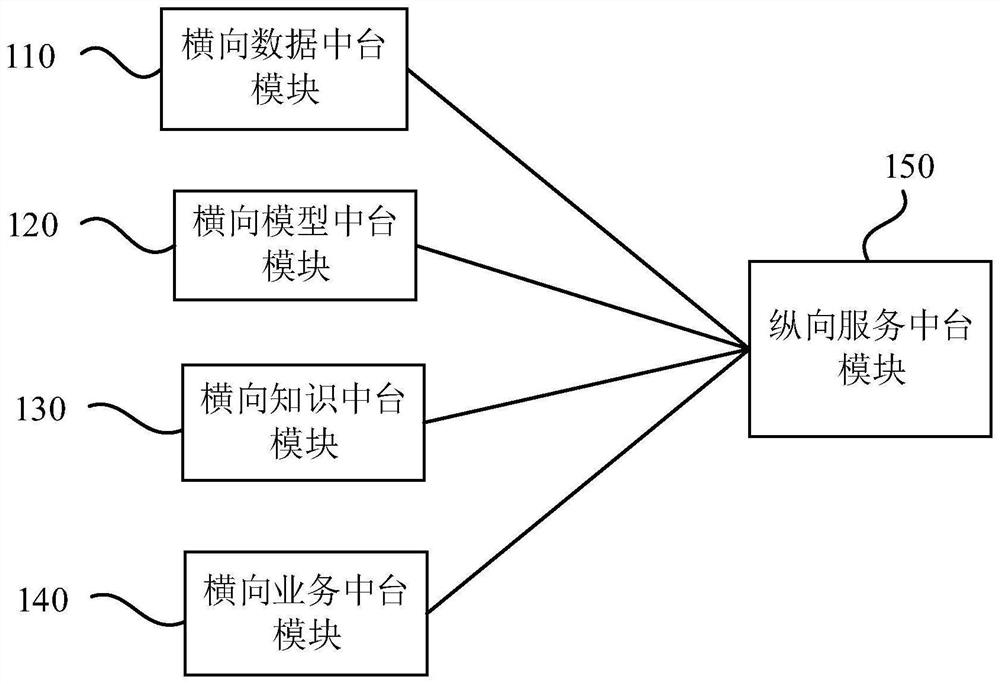

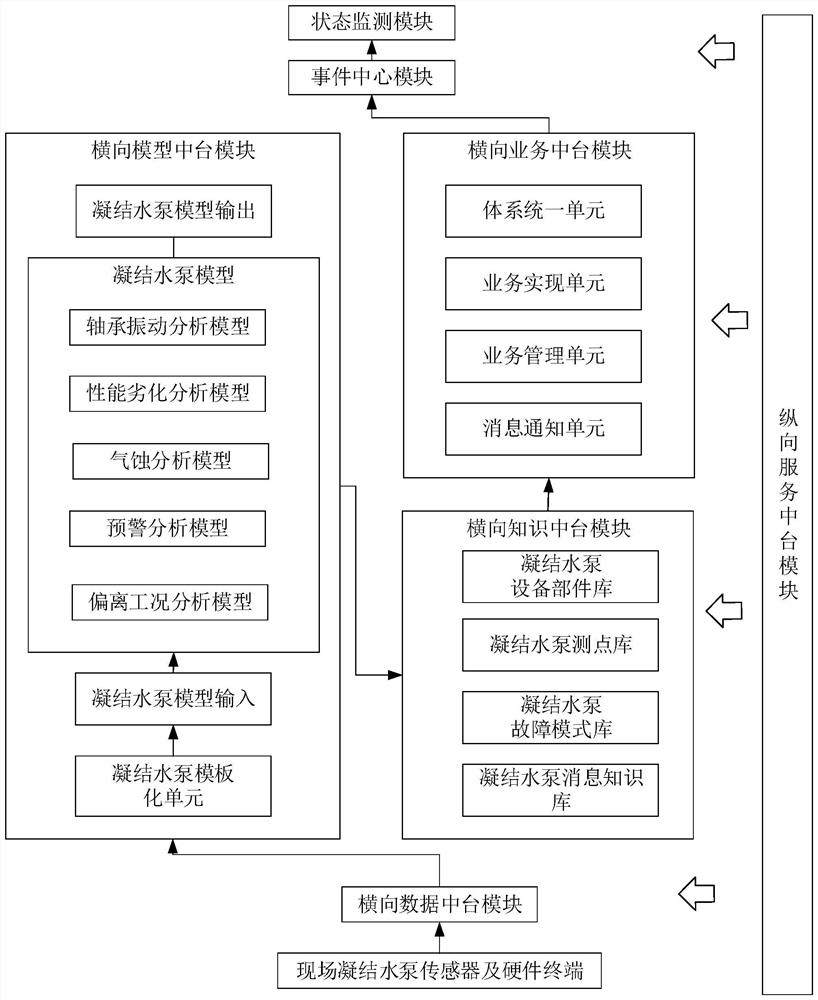

Intelligent power station middle platform system

PendingCN113807663AEliminate information silosImprove the level of intelligent operationDatabase management systemsCircuit arrangementsTelecommunicationsPower station

The invention discloses an intelligent power station intermediate station system which comprises a transverse data intermediate station module, a transverse model intermediate station module, a transverse knowledge intermediate station module, a transverse business intermediate station module and a longitudinal service intermediate station module, and all the transverse intermediate station modules are called through a longitudinal service calling module. Through the technical scheme of the invention, longitudinal sharing among the transverse data middle station module, the transverse business middle station module, the transverse model middle station module and the transverse knowledge middle station module can be realized, services are provided for the transverse middle station modules through the longitudinal service middle station module, fusion and intercommunication among the modules are realized, information islands are eliminated. And the intelligent operation level is improved.

Owner:SHANGHAI POWER EQUIP RES INST

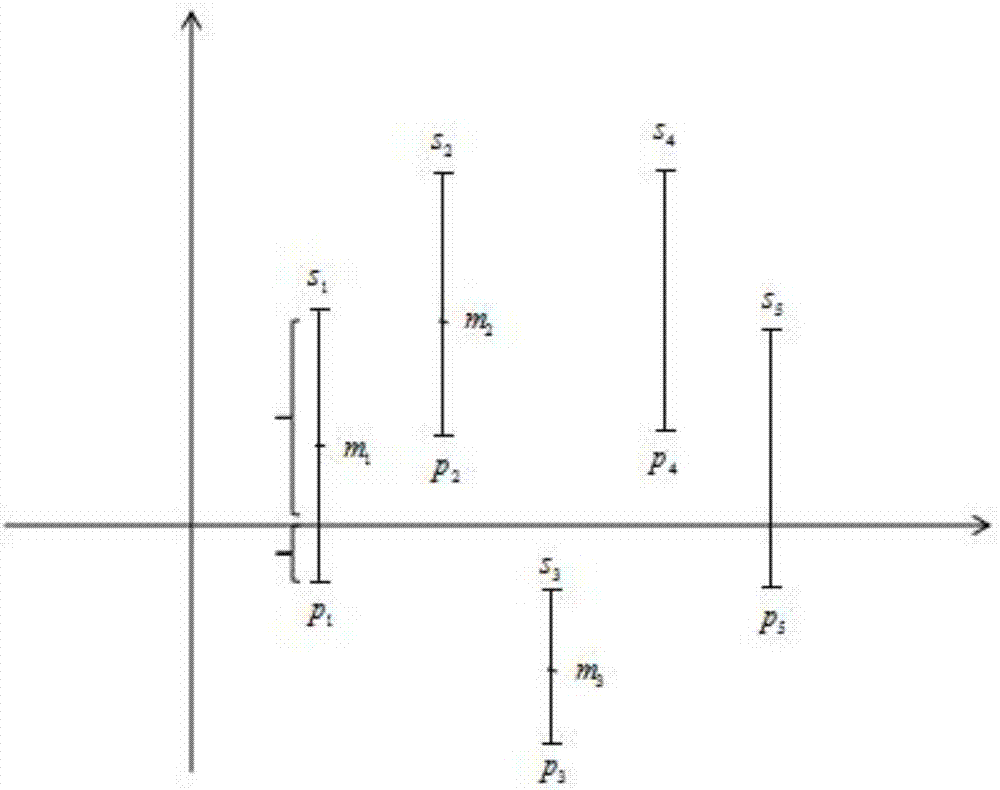

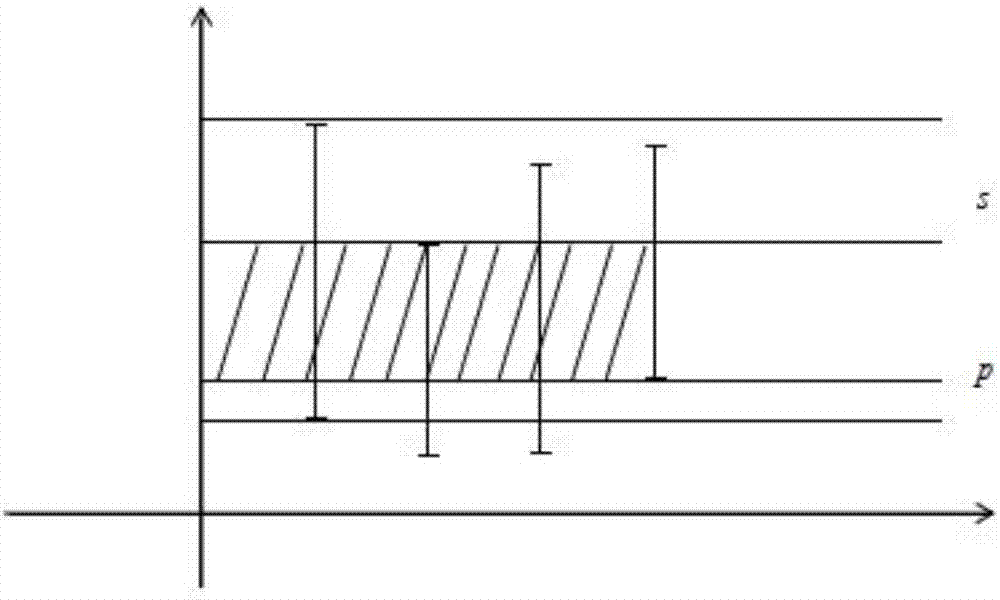

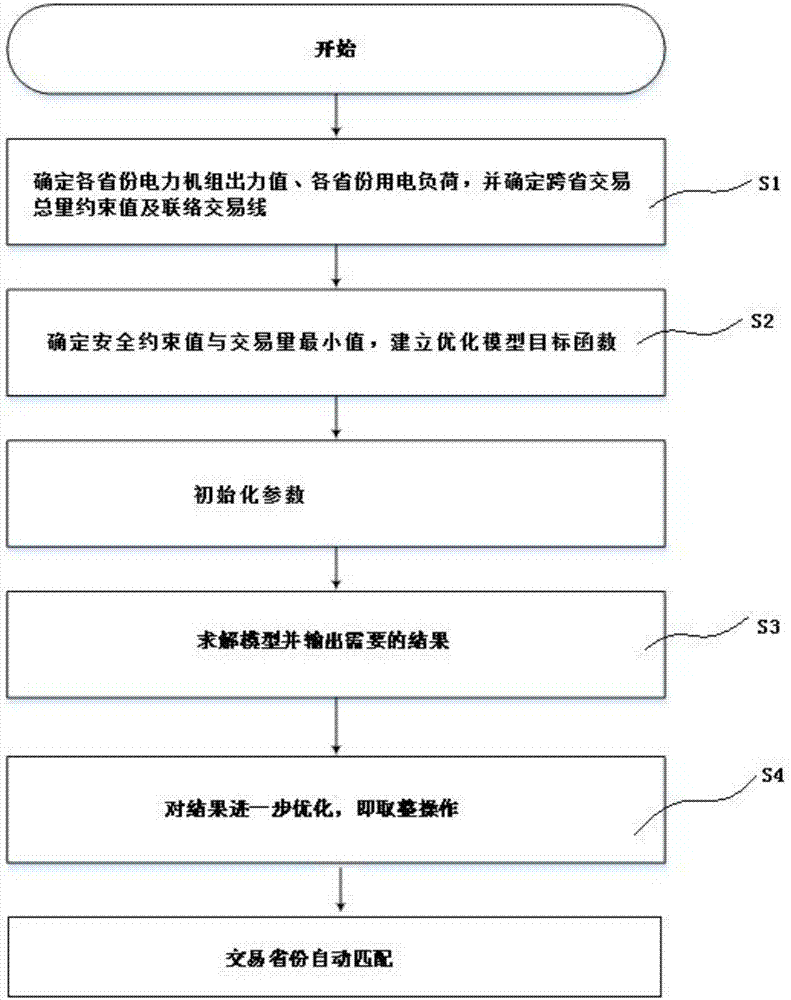

Inter-province link line power consumption transaction coordinated networking matching method

ActiveCN107346471AImprove coordination and linkage abilityIncrease profitResourcesResource utilizationPower grid

The invention relates to an inter-province link line power consumption transaction coordinated networking matching method which comprises the steps of on the condition that a power grid inter-province transaction restriction and safety restriction constraining are satisfied, determining an electric power amount which requires purchasing or selling in real time; determining a safety restraining value and a least transaction amount, establishing an optimization model target function, calculating the optimization model target function, and obtaining an optimal connection transaction total amount; calculating a transaction amount matching value between provinces, using the transaction amount to be purchased by each province as an element for forming a set A, and using the transaction amount to be sold as an element for forming a set B, performing order reducing arrangement on the elements in the set A and the set B, and acquiring the province with highest to-be-purchased transaction amount and the province with highest to-be-sold transaction amount for transaction. The inter-province link line power consumption transaction coordinated networking matching method has technical effects of realizing real-time recommending for the inter-province electric power transaction, improving inter-province power grid coordination and linkage capability, improving electric power utilization rate, and optimizing resource utilization.

Owner:西安图迹信息科技有限公司

Carriage control system and control method of component transfer vehicle for nuclear fusion device

InactiveCN103640531BGuaranteed teleoperationImprove the level of intelligent operationVehicles with cranesElectric/fluid circuitWork taskNuclear fusion

The invention relates to a part transport truck compartment control system applied to a nuclear fusion device. The part transport truck compartment control system applied to the nuclear fusion device comprises a main controller. The input end of the main controller is connected with the output end of a feedback detection unit and the output end of the main controller is connected with the input ends of a hydraulic base station control unit, a bidirectional sealing door control unit and a dragging mechanism control unit. The input and output end of the main controller is communicated with an upper computer through a wireless communication module and connected with the input and output end of a man-machine interaction device. The invention further discloses a control method of the part transport truck compartment control system applied to the nuclear fusion device. By the adoption of the part transport truck compartment control system applied to the nuclear fusion device and the method of the part transport truck compartment control system applied to the nuclear fusion device, stepped voltage regulation and flow change control can be achieved, logic sequence operation can be performed according to work tasks and wireless communication with the upper computer is carried out in real time. Remote operation of a transport truck compartment system under the nuclear fusion environment is effectively ensured, operation smoothness and operation safety are ensured and the intelligence operation level of a part transport truck is effectively improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

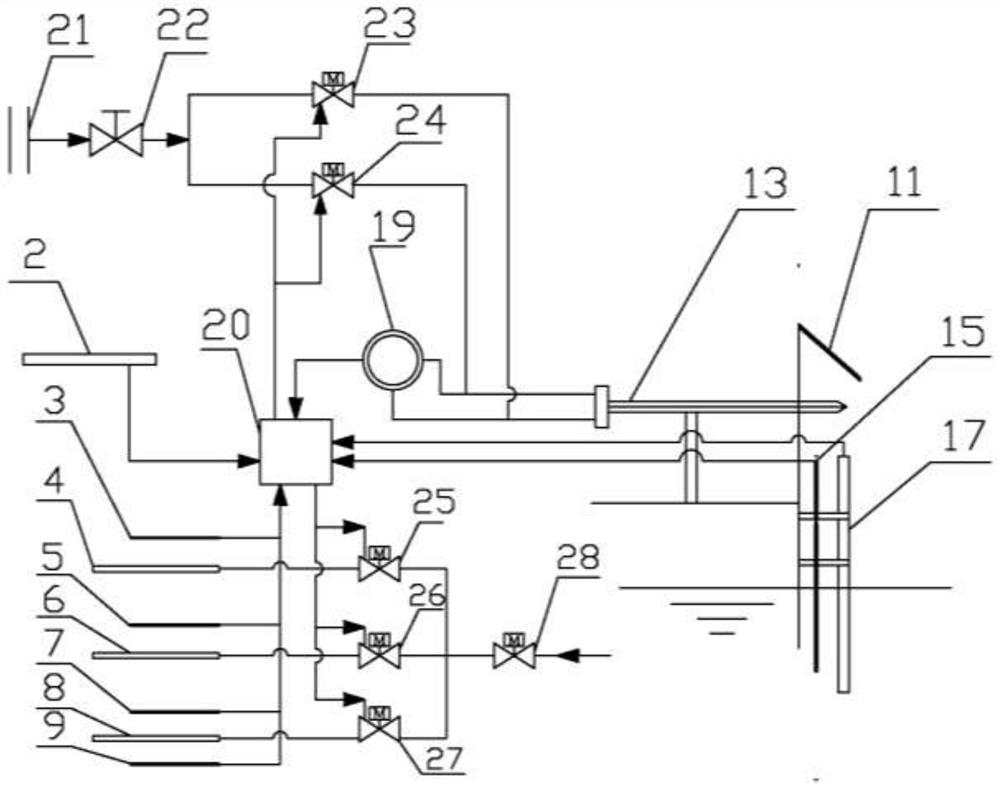

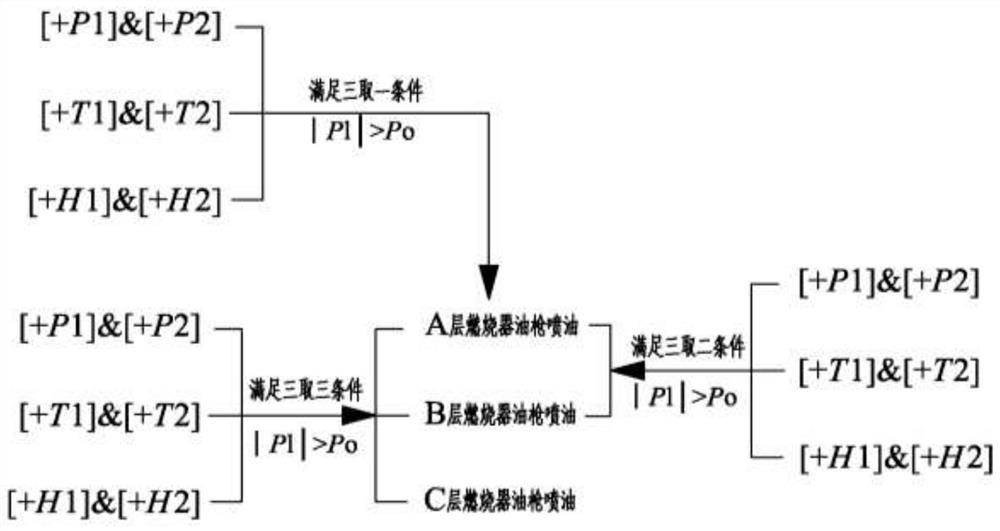

Hydraulic deslagging type corner tangential type boiler clinker falling monitoring and automatic combustion stabilization system

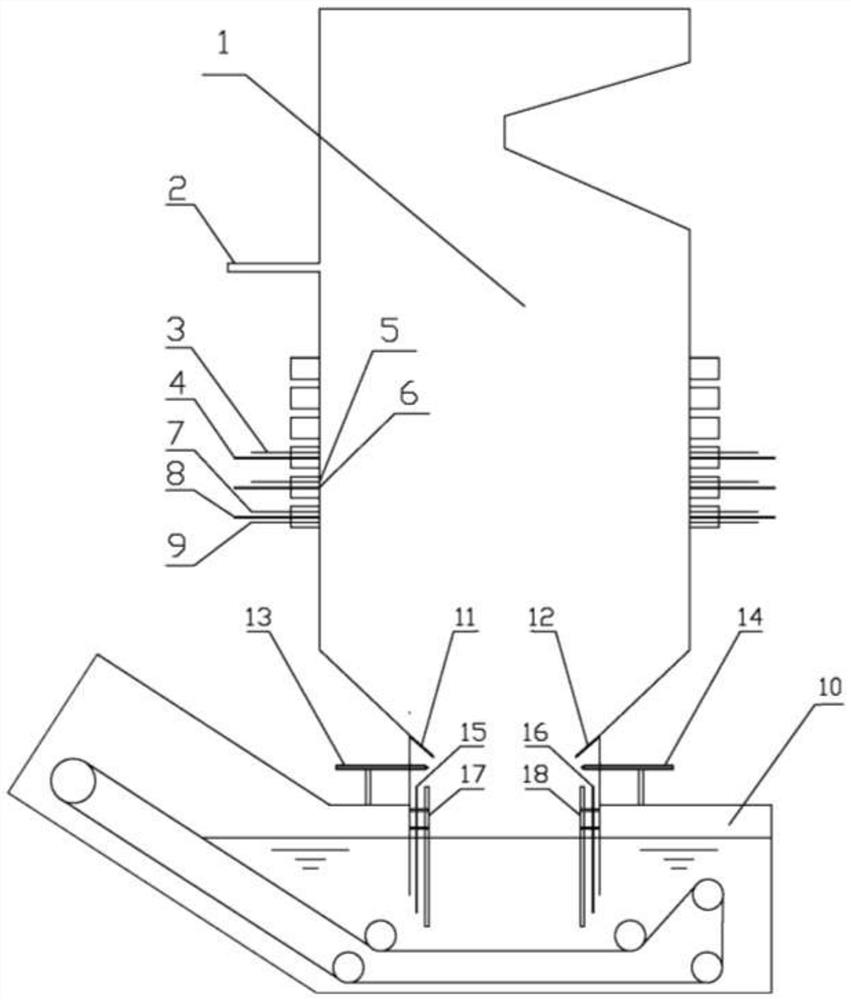

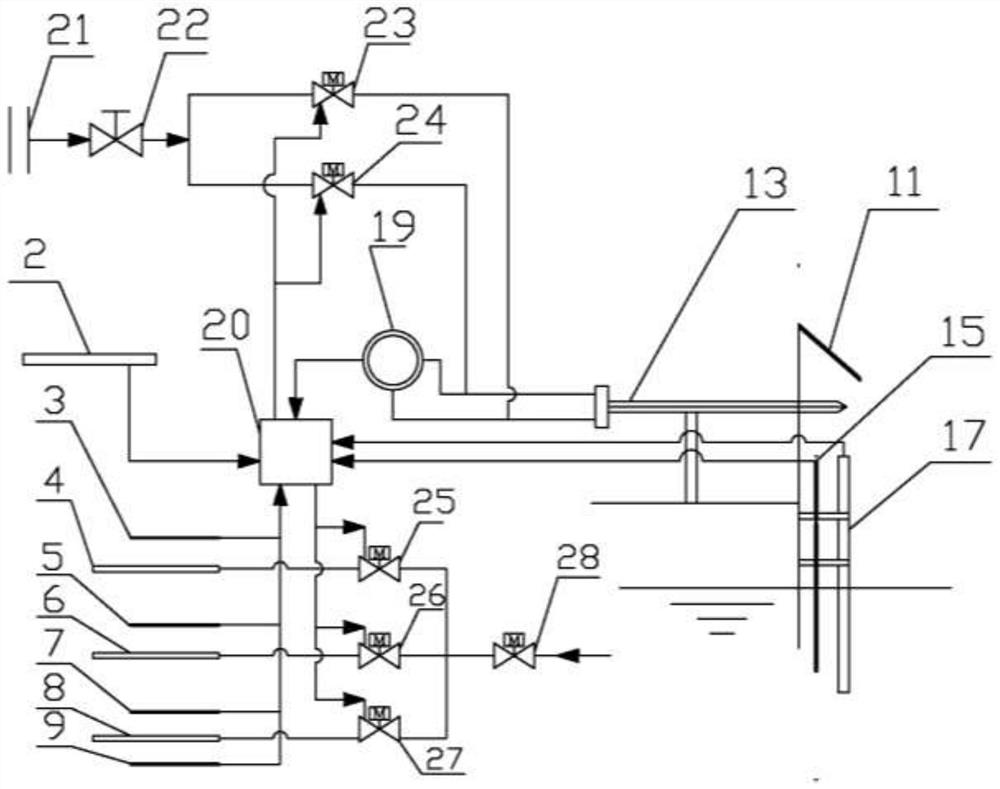

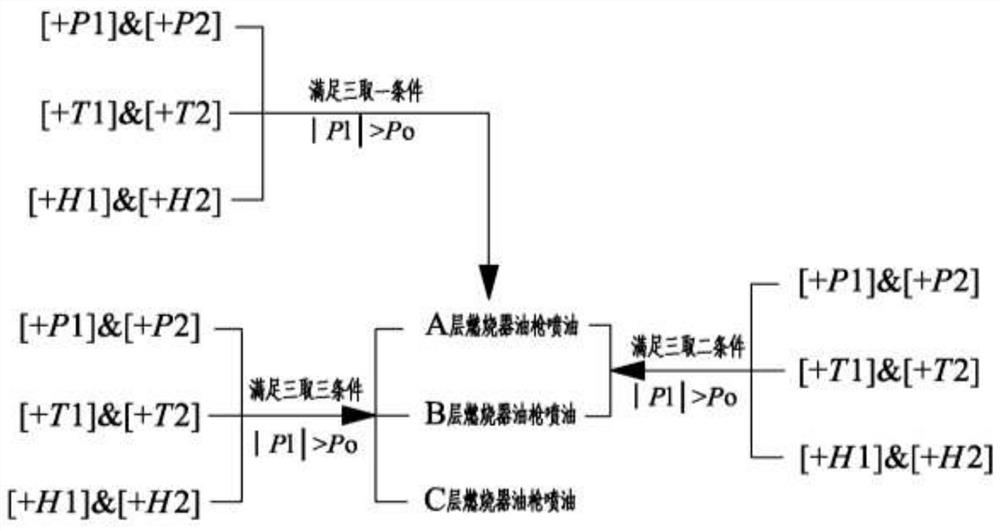

ActiveCN111637488AStable combustion operationImprove the level of intelligent operationDesign optimisation/simulationSpecial data processing applicationsAutomotive engineeringChain conveyor

The invention discloses a hdraulic deslagging type corner tangential type boiler clinker falling monitoring and automatic combustion stabilization system. The system comprises a hearth, the hearth isprovided with a hearth pressure measuring point, a C-layer combustor flame detection probe, a C-layer combustor oil gun, a B-layer combustor flame detection probe, a B-layer combustor oil gun, an A-layer combustor first flame detection probe, an A-layer combustor oil gun, and an A-layer combustor second flame detection probe are arranged in the combustor area from top to bottom in sequence, a first baffle and a second baffle are connected with dry bottom hoppers on the left side and the right side of the hearth correspondingly, the bottom of the hearth is provided with a submerged chain conveyor, a first dynamic pressure sensor, a first thermocouple and a first electronic liquid level sensor are arranged on the left side of the submerged chain conveyor, a second dynamic pressure sensor, asecond thermocouple and a second electronic liquid level sensor are arranged on the right side of the submerged chain conveyor, the unit non-stop problem caused by boiler clinker falling can be effectively solved, and the unit safe and stable running level can be improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

An operating mechanism and control method for a permanent magnet salient pole motor of a high voltage circuit breaker

ActiveCN103560039BImprove the level of intelligent operationFew partsAC motor controlHigh-tension/heavy-dress switchesEngineeringDrive motor

Owner:SHENYANG POLYTECHNIC UNIV

A hydraulic slag removal type four-corner cut-round boiler coke drop monitoring and automatic combustion stabilization system

ActiveCN111637488BStable combustion operationImprove the level of intelligent operationDesign optimisation/simulationSpecial data processing applicationsThermodynamicsCombustor

The invention discloses a hydraulic slag removal type four-corner tangential circular boiler coke drop monitoring and automatic combustion stabilization system, which includes a furnace, the furnace pressure measuring points are arranged in the furnace, and C-layer burners are arranged sequentially from top to bottom in the burner area Fire detection probe, C layer burner oil gun, B layer burner fire detection probe, B layer burner oil gun, A layer burner No. 1 fire detection probe, A layer burner oil gun and A layer burner No. 2 fire Detection probe; the No. 1 baffle and the No. 2 baffle are respectively connected to the cold ash buckets on the left and right sides of the furnace; the bottom of the furnace is equipped with a slag scraper, No. 1 dynamic pressure sensor, No. 1 thermocouple and No. 1 electronic liquid level sensor Arranged on the left side of the slag scraper; No. 2 dynamic pressure sensor, No. 2 thermocouple and No. 2 electronic liquid level sensor are arranged on the right side of the slag scraper. The invention can effectively avoid the non-stop problem of the unit due to the coking loss of the boiler, and improve the safe and stable operation level of the unit.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

A method for evaluating the state of multi-dimensional power transmission equipment

ActiveCN104732058BGuaranteed uptimeImprove the level of intelligent operationSpecial data processing applicationsTime informationSimulation

The present invention first establishes a state evaluation model of power transmission equipment with a multi-layer structure, and establishes a special evaluation time period and a special line section. Then, the cumulative deduction method is used as the basic scoring method for each parameter in the evaluation model, and the actual weight and actual deduction value of each parameter are given in combination with the evaluation period and evaluation section. Finally, according to the parameter score value, the score value of each sub-component, tower section, and whole of the power transmission equipment is calculated in turn, and the overall status of the power transmission equipment is comprehensively judged by combining the two dimensions of the evaluation period and the evaluation section. The present invention integrates information of three dimensions of line score, time and space, and the state evaluation method is comprehensive and expandable, and the final multi-dimensional evaluation conclusion is close to the real operating state of the power transmission equipment.

Owner:SHANGHAI JIAO TONG UNIV

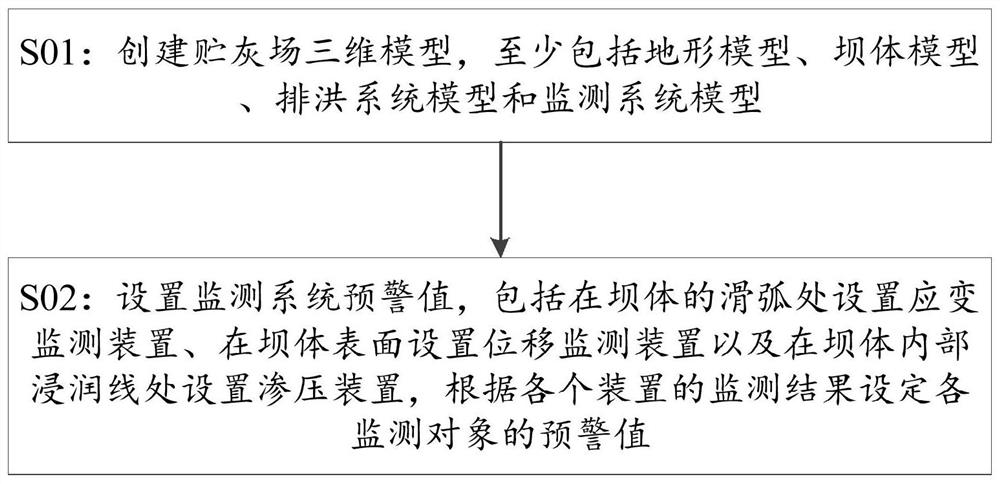

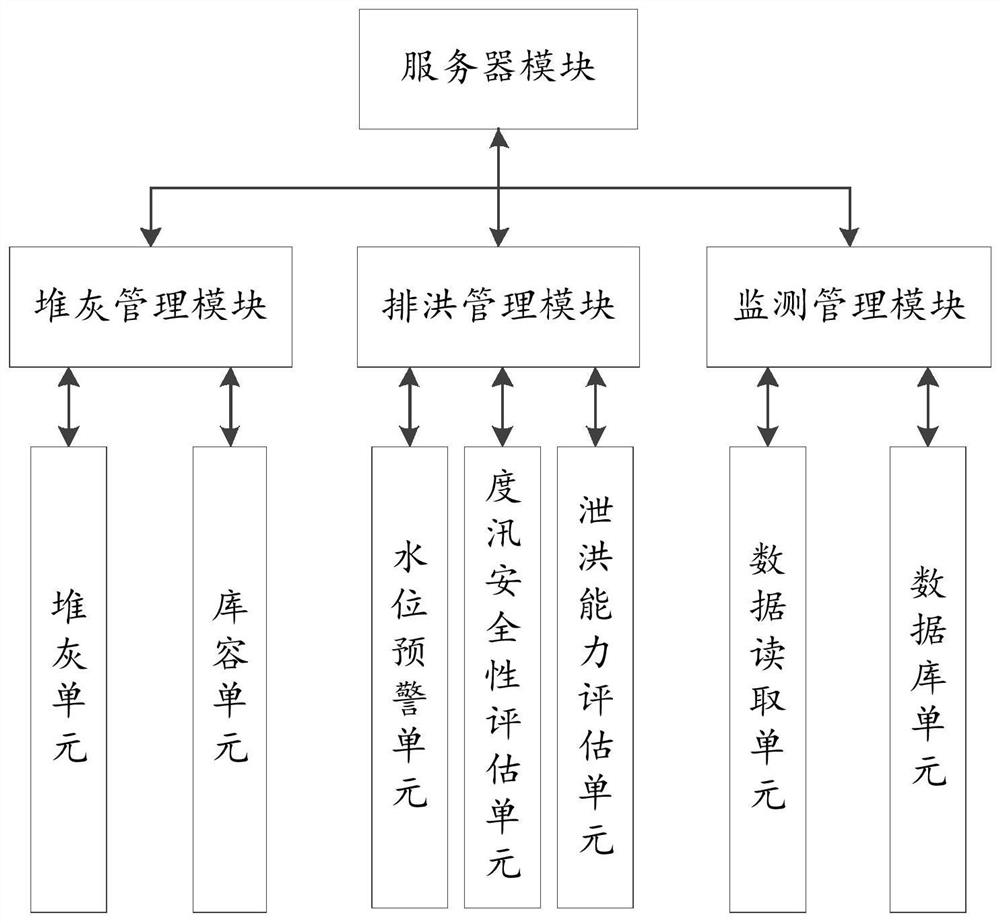

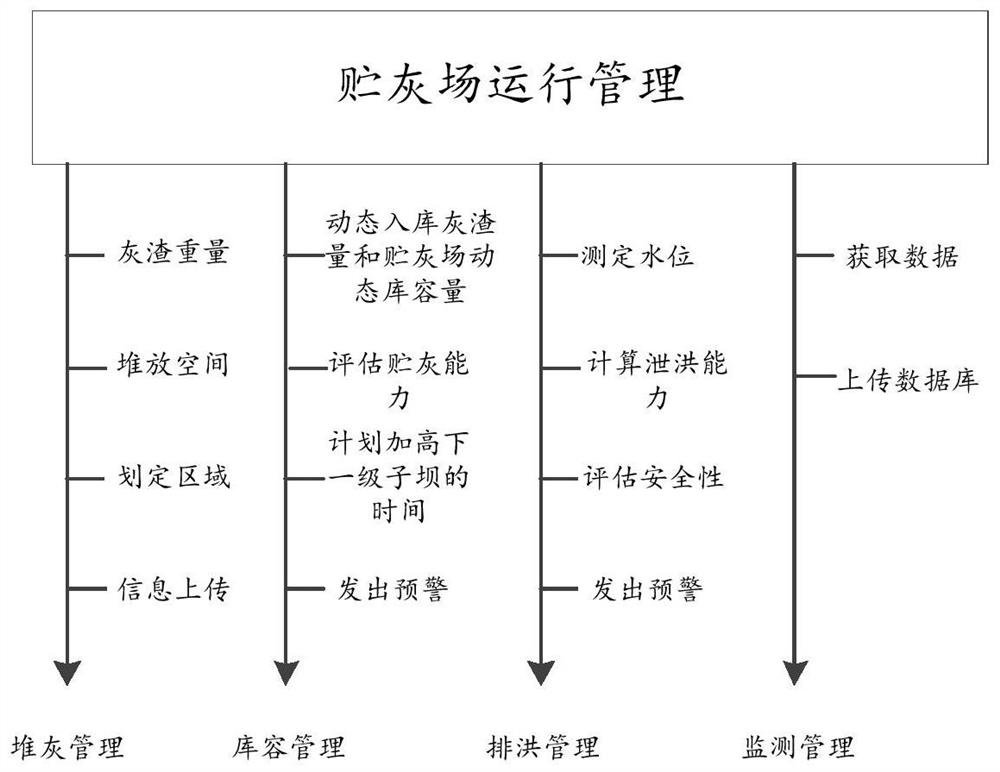

Ash storage yard operation management system construction method, management system and management method

ActiveCN113254737AImprove information management levelEnhanced Security AssessmentData processing applicationsClimate change adaptationSafety indexProcess engineering

The invention relates to the technical field of ash storage yard management, in particular to an ash storage yard operation management system construction method, an ash storage yard operation management system and an ash storage yard operation management method, and aims to construct an ash storage yard management system in a more reasonable mode, carry out practical and effective operation management on an ash storage yard, improve the comprehensive management control degree of the ash storage yard and improve the safety index of the ash storage yard. According to the construction method for the operation management system of the ash storage yard, the ash storage yard model closer to the real situation can be constructed, the constructed system can display the operation situation of the ash storage yard through a visual three-dimensional model, various data of the actual ash storage yard are monitored in real time, operation management records are provided, the informatization management level of the ash storage yard is improved, the safety assessment of the ash storage yard is enhanced, the operation risk of the ash storage yard is reduced, and a guarantee is provided for the safe operation of the ash storage yard.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

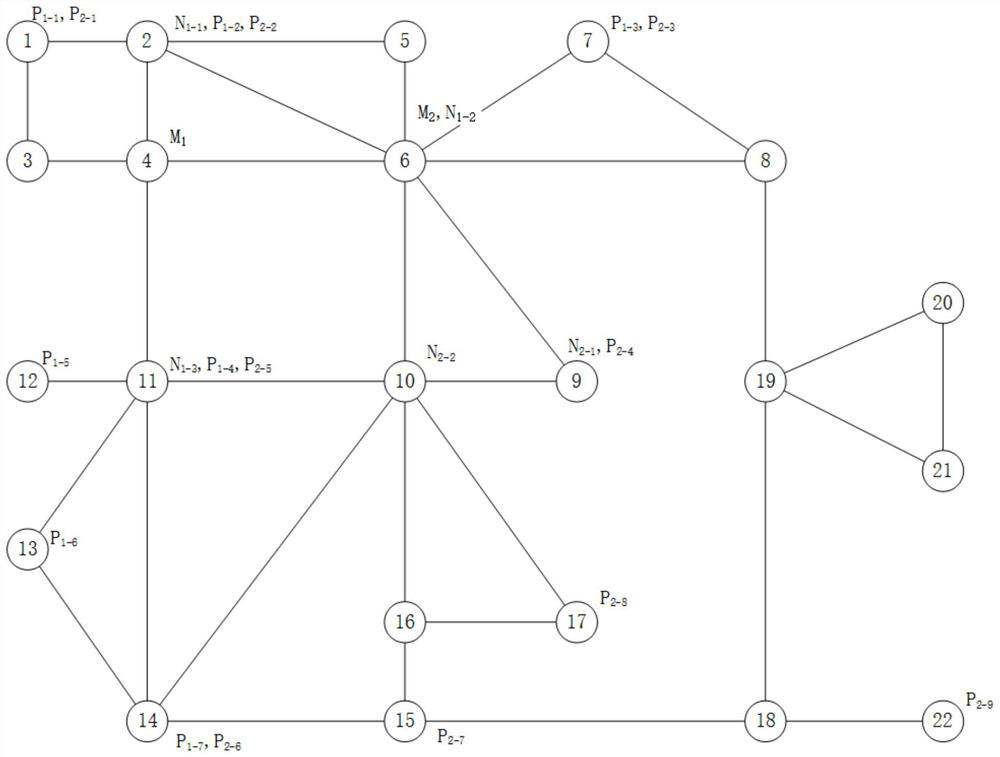

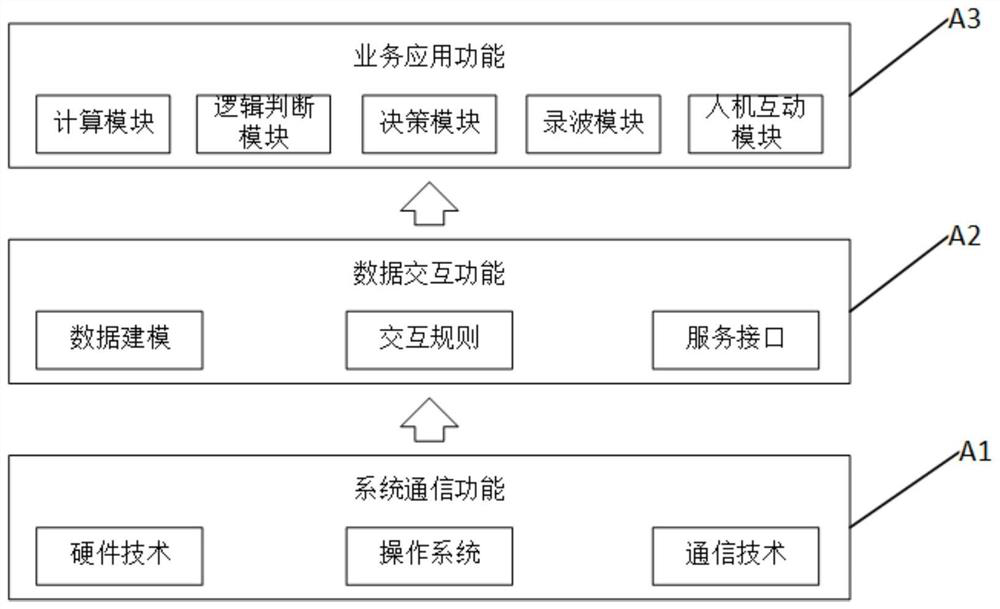

Power grid distributed intelligent safety and stability control system architecture method

PendingCN114745165AImprove operational reliabilityImprove acceleration performanceSecuring communicationInformation technology support systemDistributed intelligenceStation

The invention belongs to the technical field of power systems, and particularly relates to a distributed intelligent security and stability control system architecture method. Based on a universal security and stability control system device communication network, flexible deployment and change of multiple sets of stability control systems and stability control strategies in a power grid are achieved, devices in the system can be deployed in multiple sets of systems executing different security and stability control strategies at the same time, and the functions of a master station, a substation and an execution station of the stability control system are achieved respectively. According to the invention, information interaction and function cooperation among a plurality of independent and dispersed subsystems in the original stability control system are realized, the diversity and function redundancy of the strategy of the stability control system are increased, and the operation reliability and expandability of a power grid are improved. And meanwhile, the cost and period of the stability control system in the new construction and transformation process are reduced, and good economical efficiency is achieved.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

An intelligent and economical operation system for steam turbine generator set

ActiveCN108412558BImprove the level of intelligent operationAchieving simultaneous optimization runsSafety/regulatory devicesSteam engine plantsSteam pressureControl system

The invention relates to an intelligent economic operation system of a steam turbine generator unit. The intelligent economic operation system comprises a data acquisition module, an intelligent algorithm computation module and a control module, wherein the data acquisition module is connected with the intelligent algorithm computation module, the intelligent algorithm computation module is connected with the control module, the control module is connected with a unit DCS control system and a unit coordinated control system, the data acquisition module is used for collecting real-time operating data of the DCS system of the generator unit and transmitting to the intelligent algorithm computation module, the intelligent algorithm computation module is used for calculating the current unit load, the optimal main steam pressure of a steam turbine at the temperature of circulating water and the optimal variable frequency of a water circulating pump by virtue of a sliding pressure optimization calculation module and a water circulating pump optimization calculation module, the optimal main steam pressure value and the optimal variable frequency value of the water circulating pump are transmitted to the unit DCS control system and the unit coordinated control system by virtue of the control system module, the unit is automatically adjusted to operate in a real-time optimization mode,and the intelligent economic operation of the steam turbine generator unit is realized.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

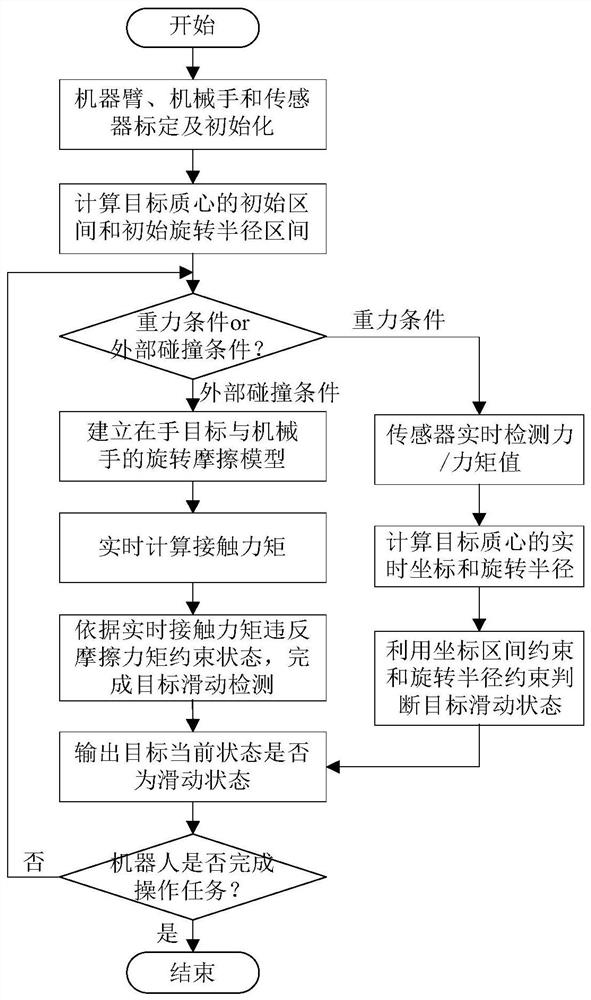

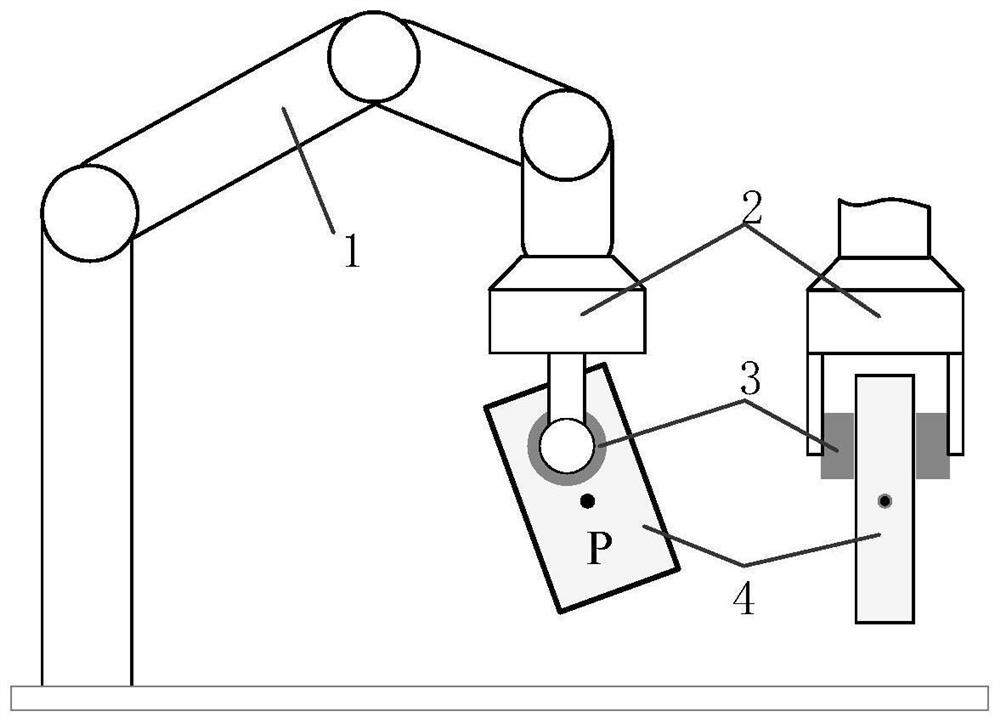

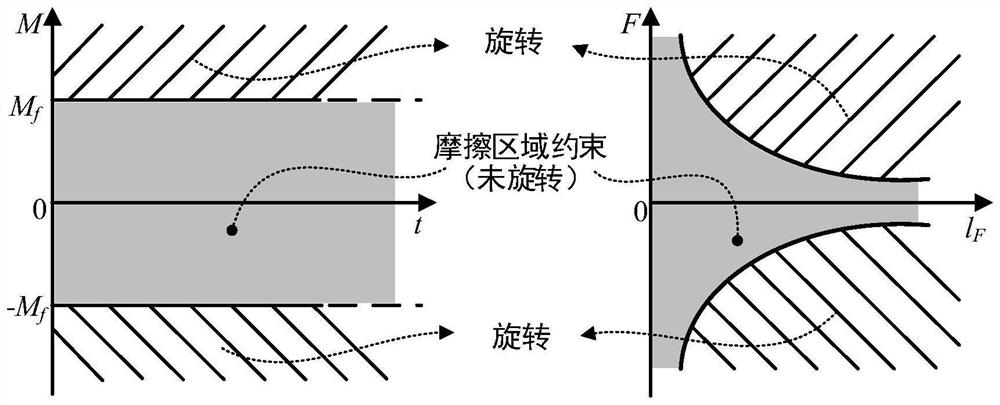

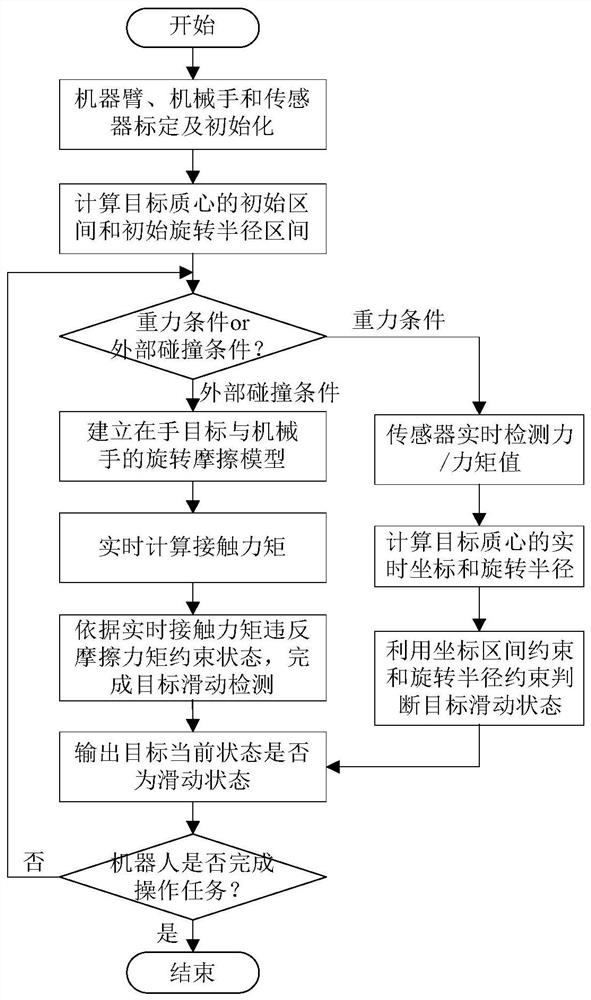

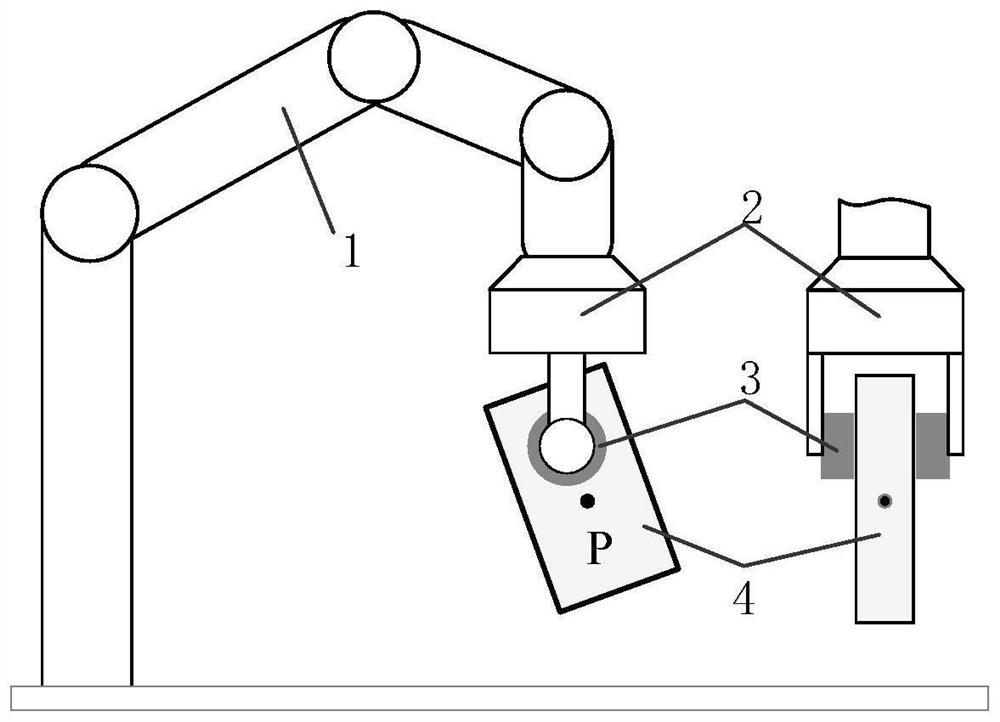

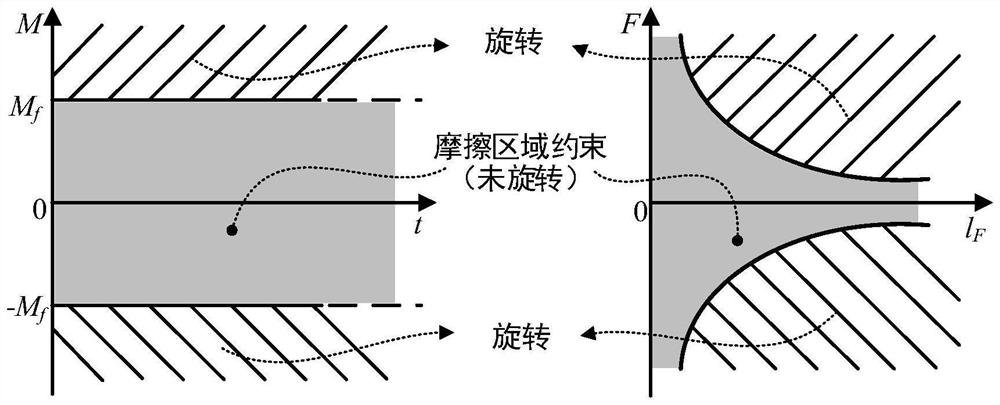

A target rotation detection method suitable for manipulator in-hand operation

ActiveCN111604901BImprove the ability to manipulate the target at handImprove the ability to operate the targetProgramme-controlled manipulatorClassical mechanicsManipulator

A target rotation detection method suitable for manipulator in-hand operation, which includes step 1: calibrating and initializing the detection system; step 2: calculating the initial coordinate interval and the initial rotation radius interval of the center of mass of the operation target in the manipulator coordinate system; Three: Use the force / torque sensor to detect the force state of the target in real time, and judge the condition of the target at this time based on the detection results; if the force / torque sensor has no pulse fluctuation output, use the rotation detection method of pure gravity conditions. Target rotation detection; if the output value of the force / torque sensor has pulse fluctuations, the rotation detection method of the external collision condition is used to detect the target rotation; Step 4: After the robot completes the rotation detection of the job target in the current state, repeat Step 3 until The robot completes the operation task of the operation target. The invention can enhance the robot's ability to perceive and operate on unknown targets.

Owner:HARBIN INST OF TECH

Object rotation detection method suitable for mechanical hand at-hand operation

ActiveCN111604901AImprove the ability to manipulate the target at handImprove the ability to operate the targetProgramme-controlled manipulatorRobot handClassical mechanics

The invention provides an object rotation detection method suitable for mechanical hand at-hand operation. The method includes the steps that a detection system is calibrated and initialized; 2, the initial coordinate section and the initial rotation radius section of the mass center of an operating object under a mechanical hand coordinate system are calculated; 3, a force / torque sensor is used for detecting the force bearing state of the operating object in real time, the condition where the operating object is located at the moment is judged according to the detection result, if the force / torque sensor is in non-pulse-fluctuation output, object rotation detection is carried out with a pure-gravity condition rotation detection method, and if the output value of the force / torque sensor isin pulse fluctuation, object rotation detection is carried out with an external-collision condition rotation detection method; and 4, after a robot completes rotation detection of the operating object in a current state, the step 3 is repeated until the robot completes operating tasks on the operating object. The perception and operation capacity of the robot for unknown objects can be enhanced.

Owner:HARBIN INST OF TECH

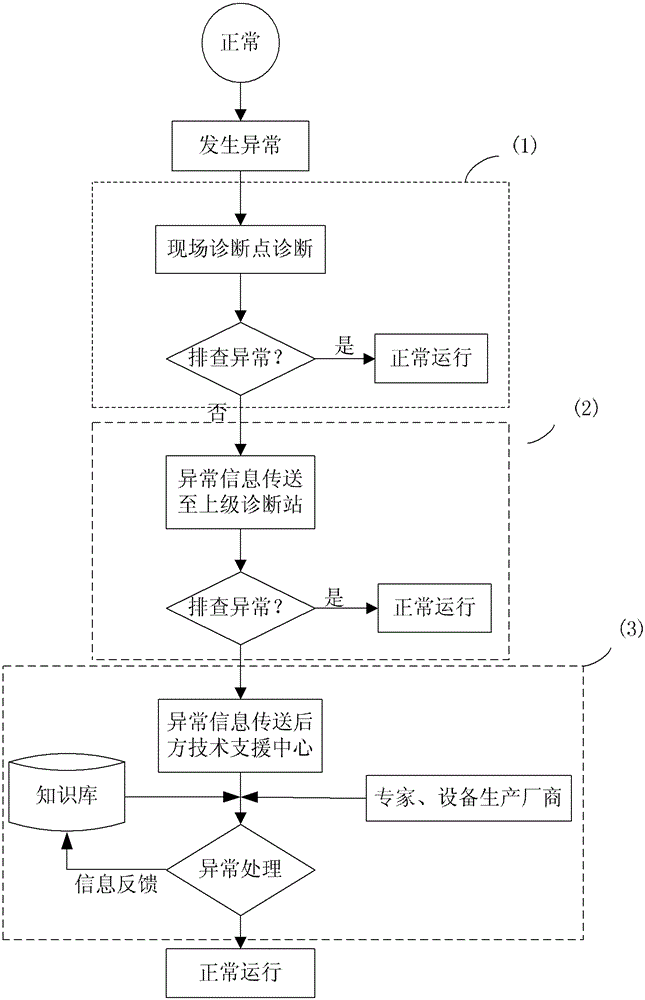

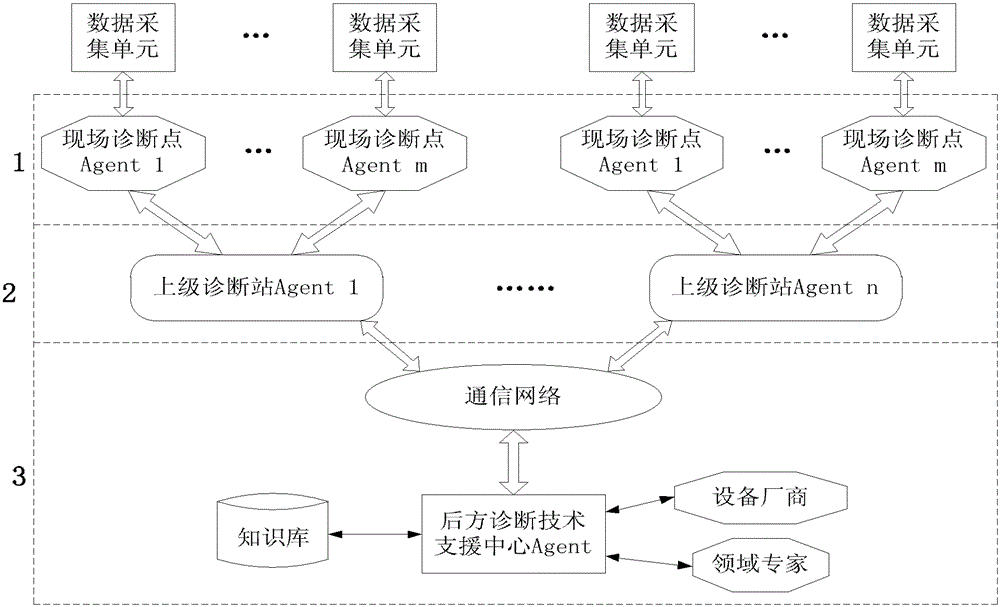

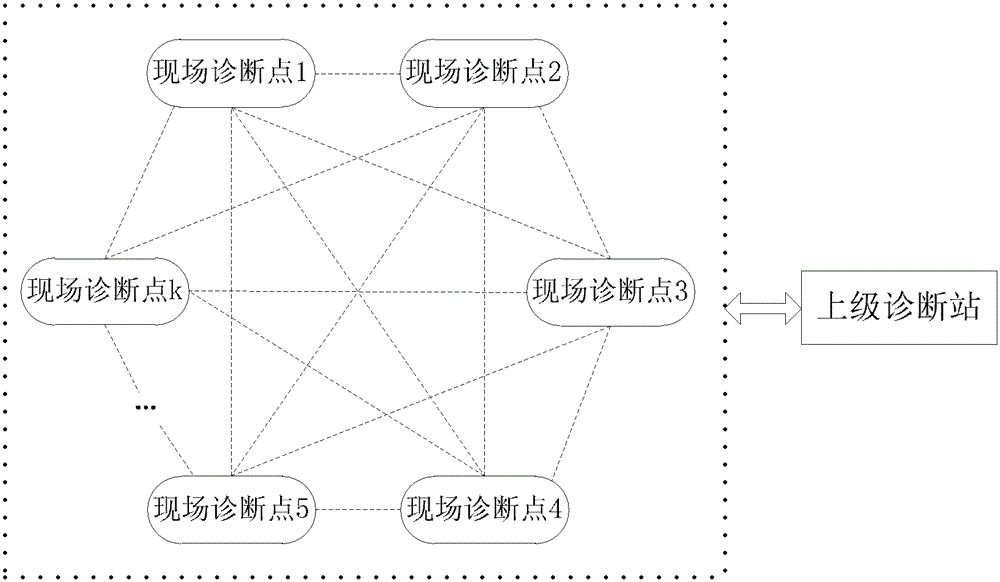

A Distributed Power Quality Remote Diagnosis Method

The invention relates to a remote diagnosis method for distributed quality of electric energy, which includes the following steps: step 1 detecting unusual conditions of quality of electric energy of power grid operation at a diagnosis point, and performing source tracing and positioning; coming to next step in case of failing to rule out the fault cause; step 2 enabling the diagnosis point to send collaborative diagnosis signals to an upper-level diagnosis station, and enabling the upper-level diagnosis station to judge and diagnose and feed back diagnosis results to the diagnosis point; coming to next step in case that the upper-level diagnosis station cannot rule out the cause of unusual conditions; and step 3 enabling the upper-level diagnosis station to send a diagnosis request to a technical support center, and enabling the technical support center to judge the cause of the unusual conditions and feed back results and solutions to the diagnosis point. The remote diagnosis method for distributed quality of electric energy provides a solution for achieving remote diagnosis of quality monitoring of electric energy, resolves existing problems that quality of electric energy of the end of an equipped grid cannot be monitored accurately, truly and timely correct analysis and judgment cannot be made, and effective measures cannot be taken, and improves intelligent operation level of the power grid and work efficiency of operating maintenance workers.

Owner:CHINA ELECTRIC POWER RES INST +1

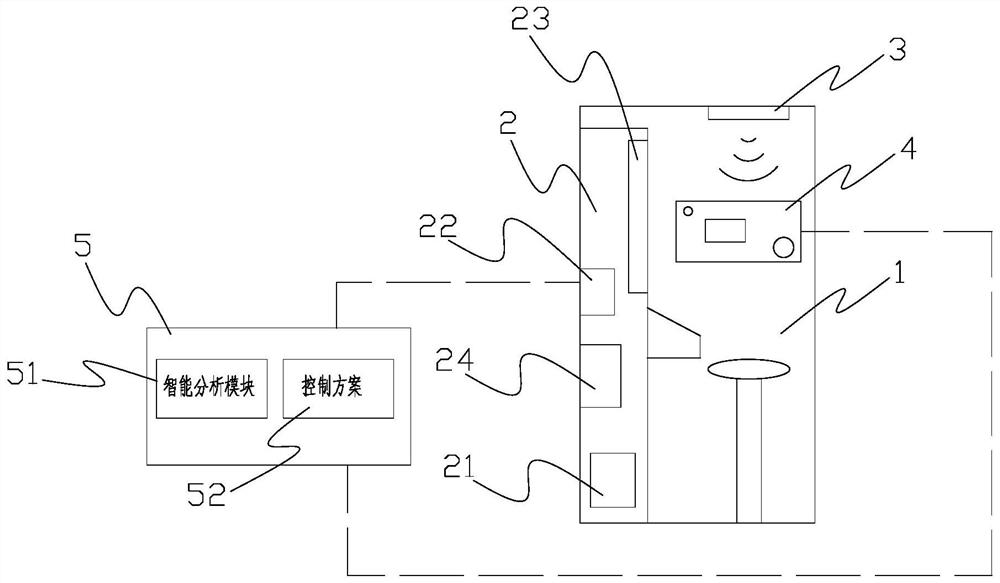

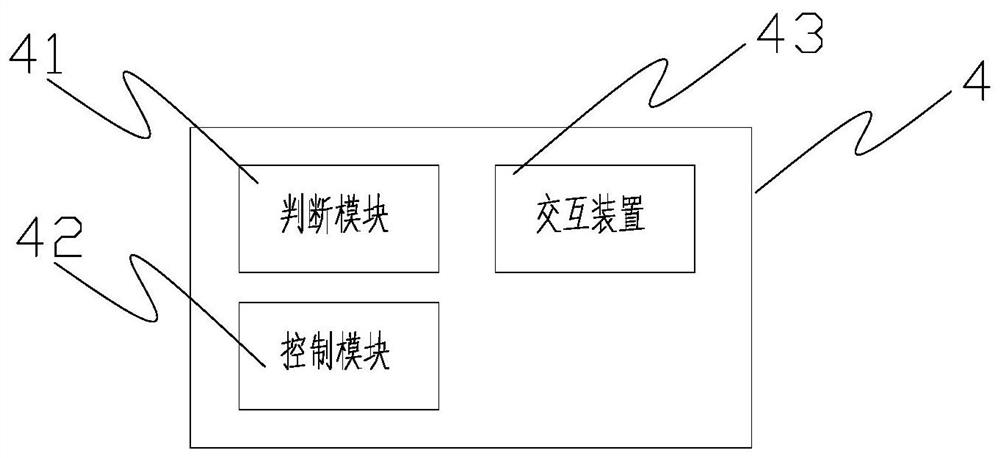

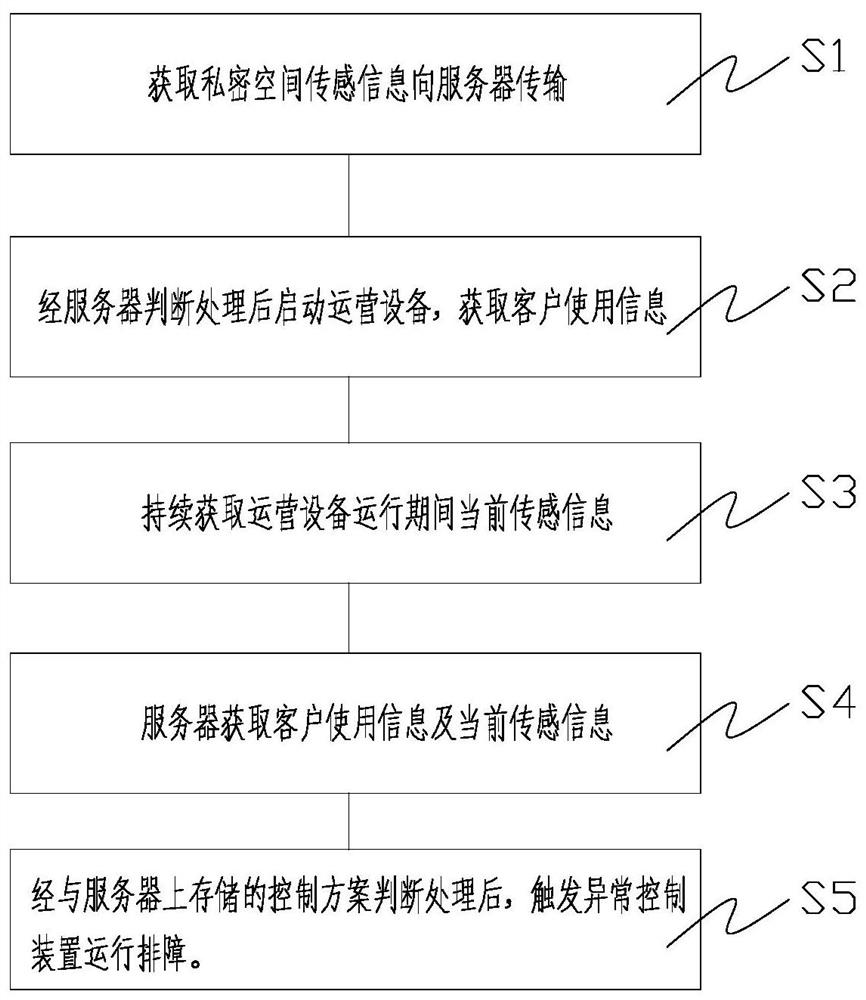

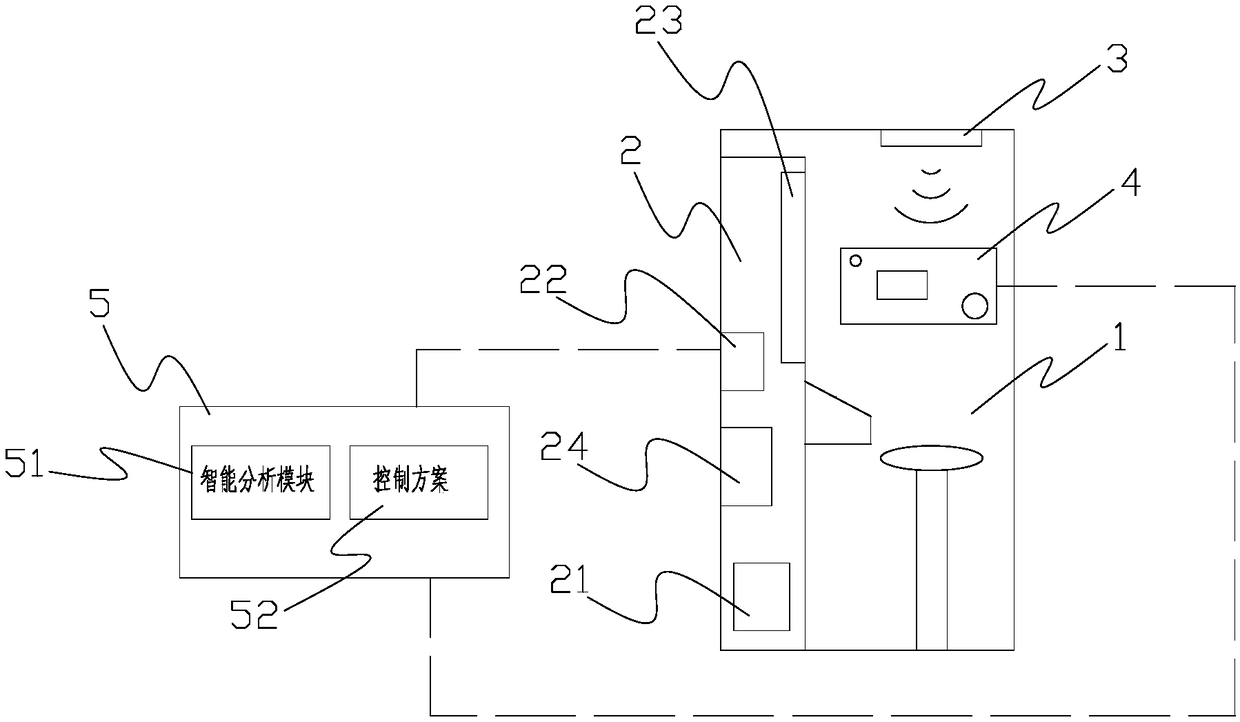

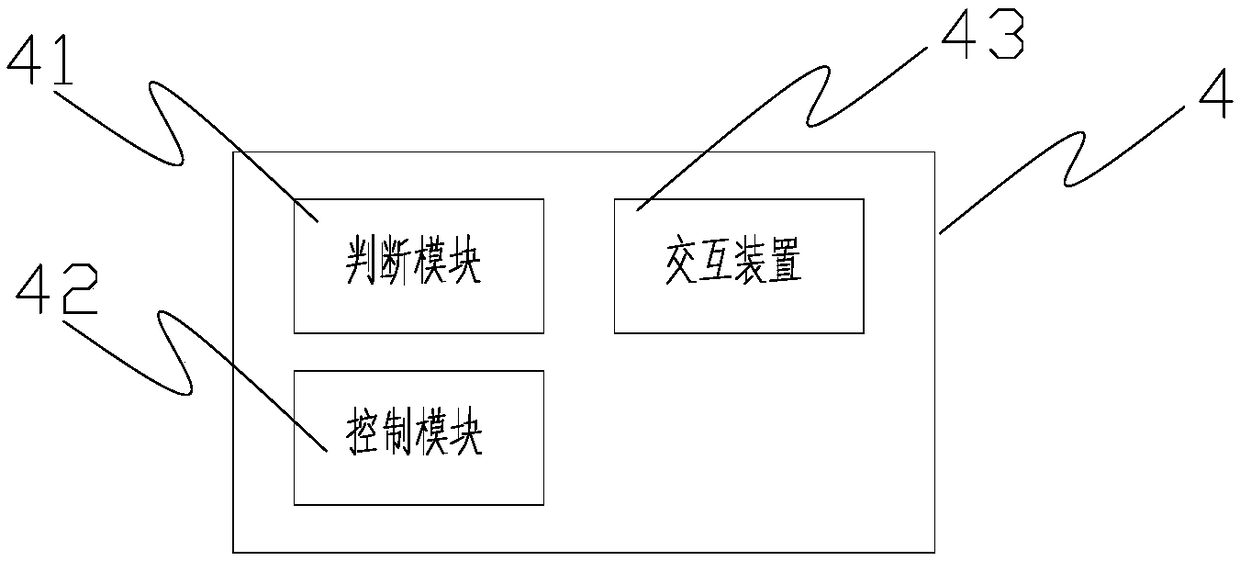

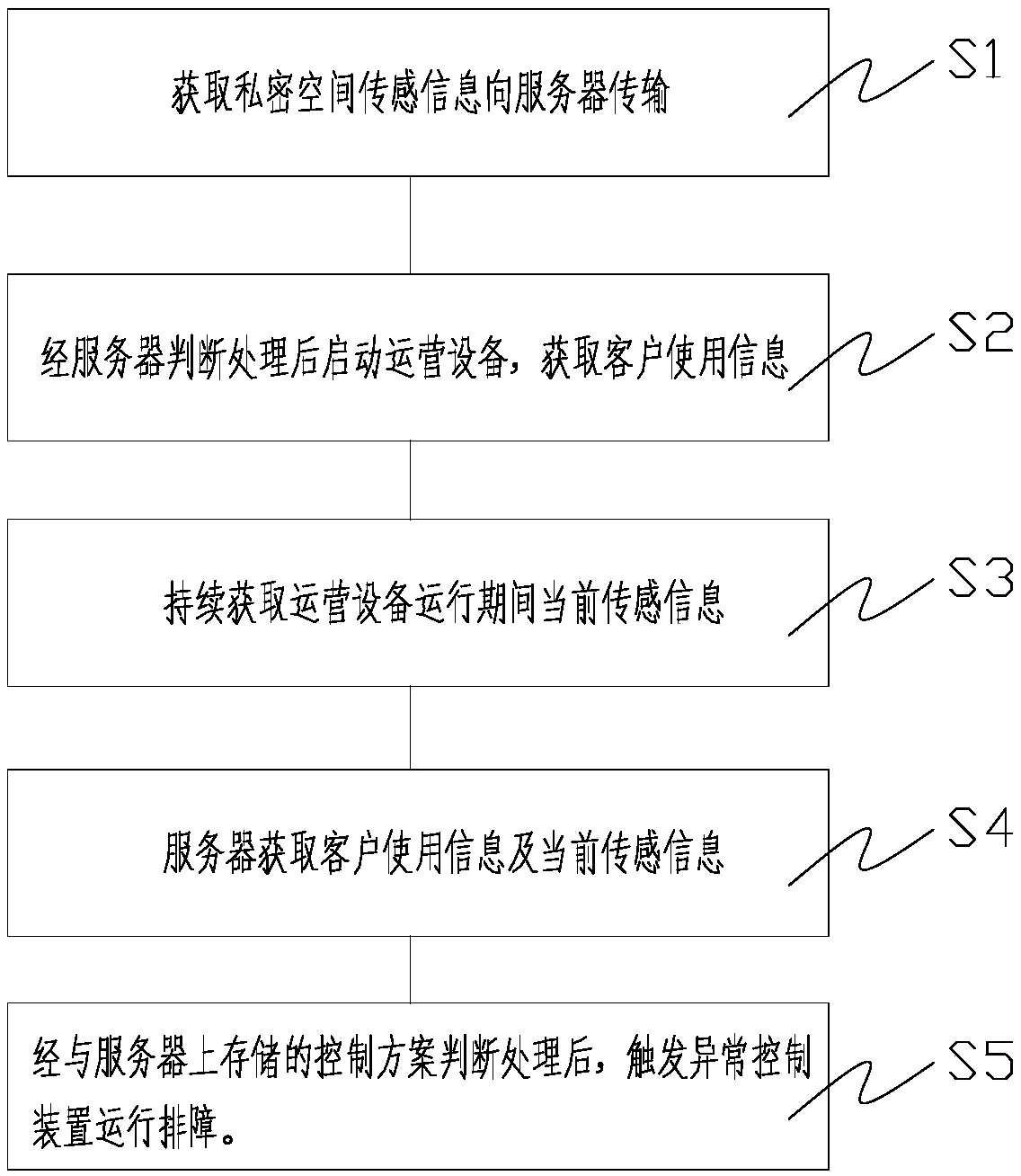

A kind of intelligent ktv operation system and method

ActiveCN109188936BReduce consumptionRealize intelligent analysis and judgmentProgramme control in sequence/logic controllersEmbedded systemEnergy consumption

The invention provides an intelligent KTV operating system. The operating system comprises an operating device, a sensing device and an abnormality control device arranged in a compact and private space with sound insulation effect. The operating device and the sensing device respectively collect customer usage information and sensing information, and send the information to a server. After the determination process is performed by a control scheme stored in the server, the abnormality control device connected to the server is started to operate, thereby effectively reducing the energy consumption and the operating costs, improving the intelligent operating levels, and bringing good customer experience.

Owner:WUXI BINGHE COMP TECH DEV CO LTD

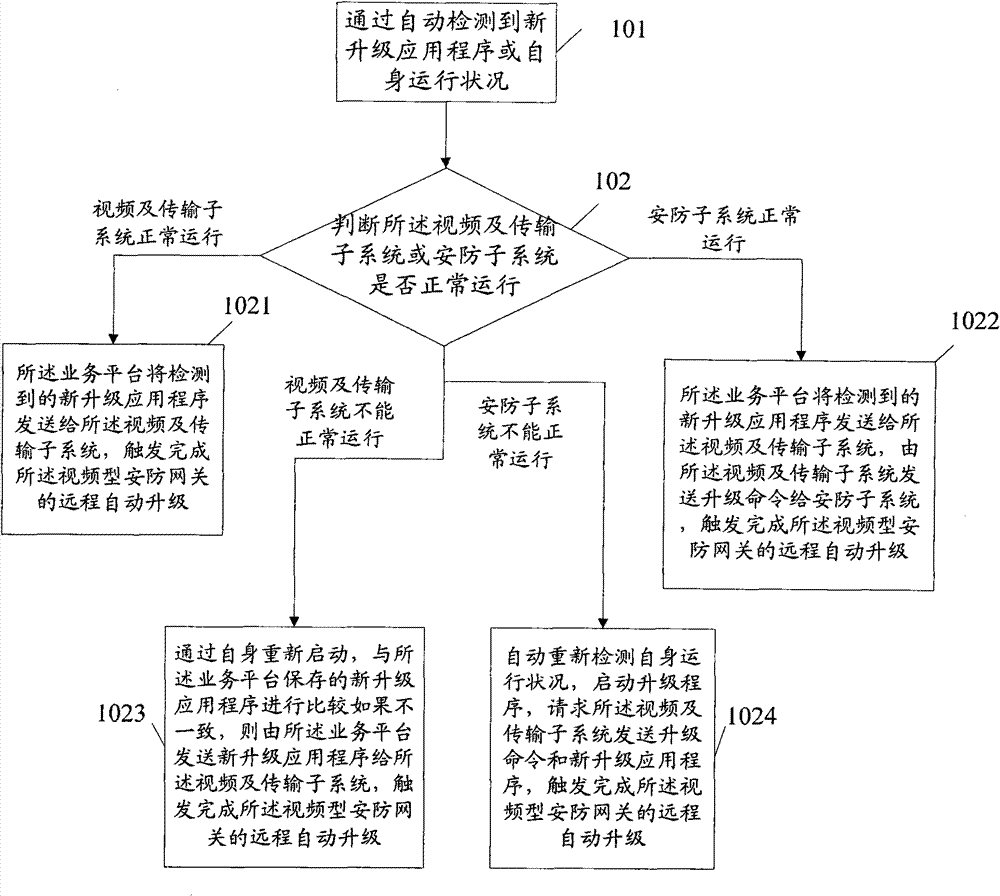

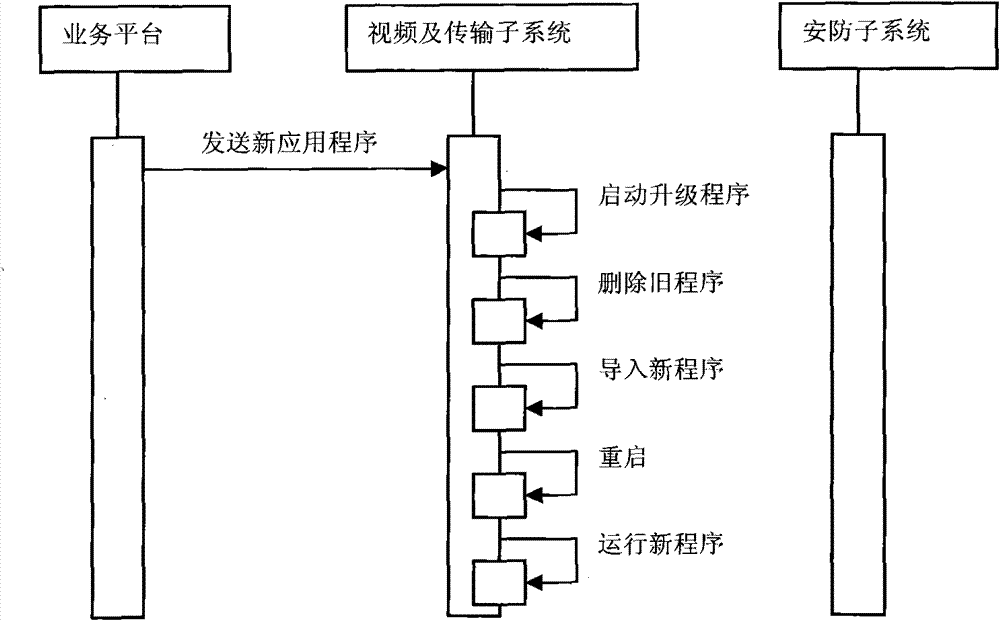

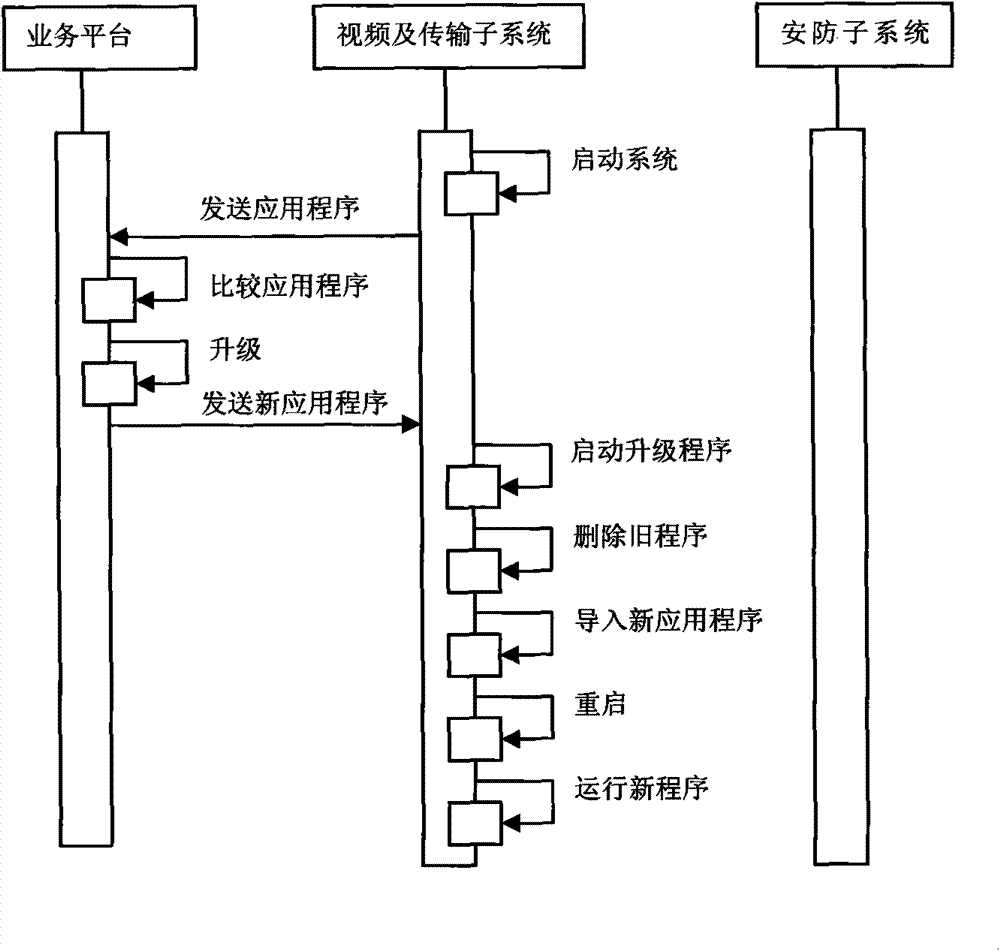

Remote automatic upgrading method and system of video-type safety-protection gateway

ActiveCN101741897BImprove the level of intelligent operationIntelligent programClosed circuit television systemsTransmissionType safetyOperating system

Owner:GUANGDONG TRI SUN ELECTRONICS TECH

System and method for taking slices for bad analysis

ActiveCN109946862BImprove automationImprove the level of intelligent operationStatic indicating devicesNon-linear opticsProduction lineData information

The invention relates to a film taking system and a film taking method for defective analysis. The film taking system for defective analysis of the present invention includes a report system and an operation system; the report system collects and displays panel information on the production line, and the operation system specifies the flow direction of the panels on the production line; The user inputs slice logic to the report system, and the report system has a built-in logic development module, and the report system selects a panel to be parsed by the logic development module according to the slice logic, and transmits the data information of the panel to be parsed to The operating system, the operating system adds process codes to the panels that need to be analyzed and performs a station jump operation on the panels that need to be analyzed, and the operating system transfers the panels that need to be analyzed to the extraction site; therefore, the present invention can realize abnormal occurrence of panels on the production line The action of pulling out slices for analysis can be made in a timely manner, which greatly improves the level of automation and intelligent operation of bad analysis and taking slices.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Intelligent KTV operating system and method

ActiveCN109188936AReduce energy consumptionReduce operating costsProgramme control in sequence/logic controllersEmbedded systemEnergy consumption

The invention provides an intelligent KTV operating system. The operating system comprises an operating device, a sensing device and an abnormality control device arranged in a compact and private space with sound insulation effect. The operating device and the sensing device respectively collect customer usage information and sensing information, and send the information to a server. After the determination process is performed by a control scheme stored in the server, the abnormality control device connected to the server is started to operate, thereby effectively reducing the energy consumption and the operating costs, improving the intelligent operating levels, and bringing good customer experience.

Owner:WUXI BINGHE COMP TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com