Hydraulic deslagging type corner tangential type boiler clinker falling monitoring and automatic combustion stabilization system

A technology of hydraulic slag removal and four-corner tangent, applied in the combustion chamber, combustion method, controlled combustion, etc., can solve the problems of high heat load burner design structure, boiler coke loss, abnormal boiler shutdown, etc., to improve intelligence Operation level, avoid non-stop problem, improve the effect of safe and stable operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0036] Example.

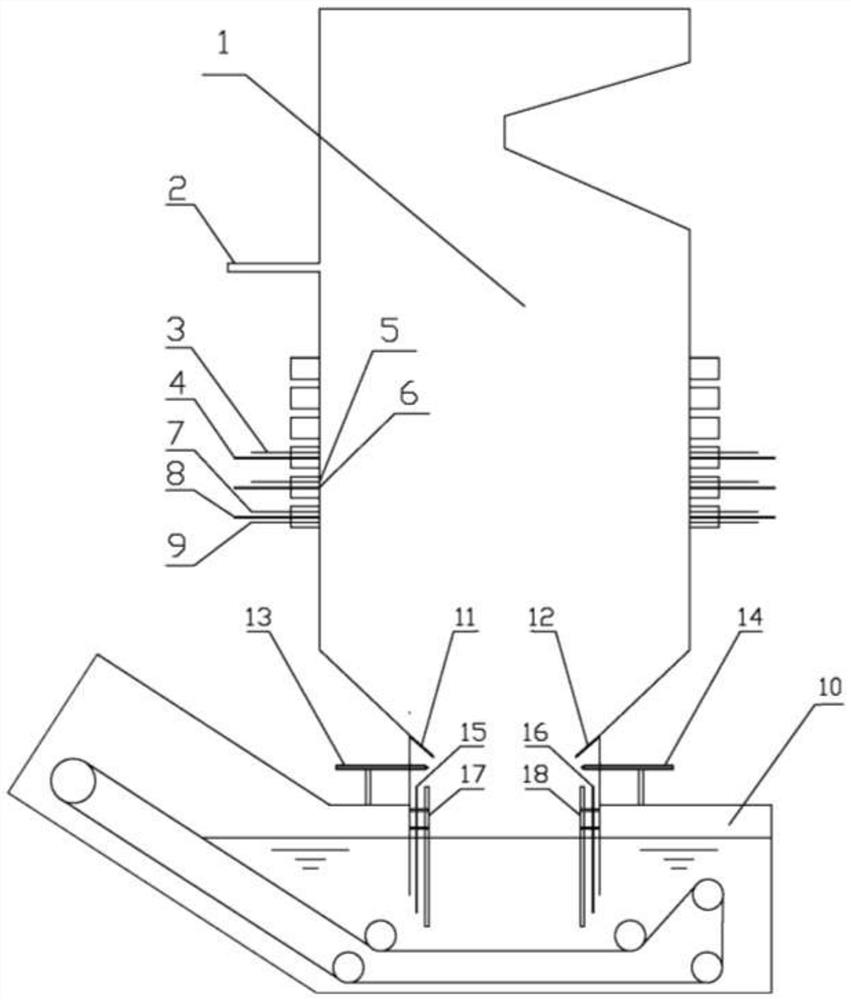

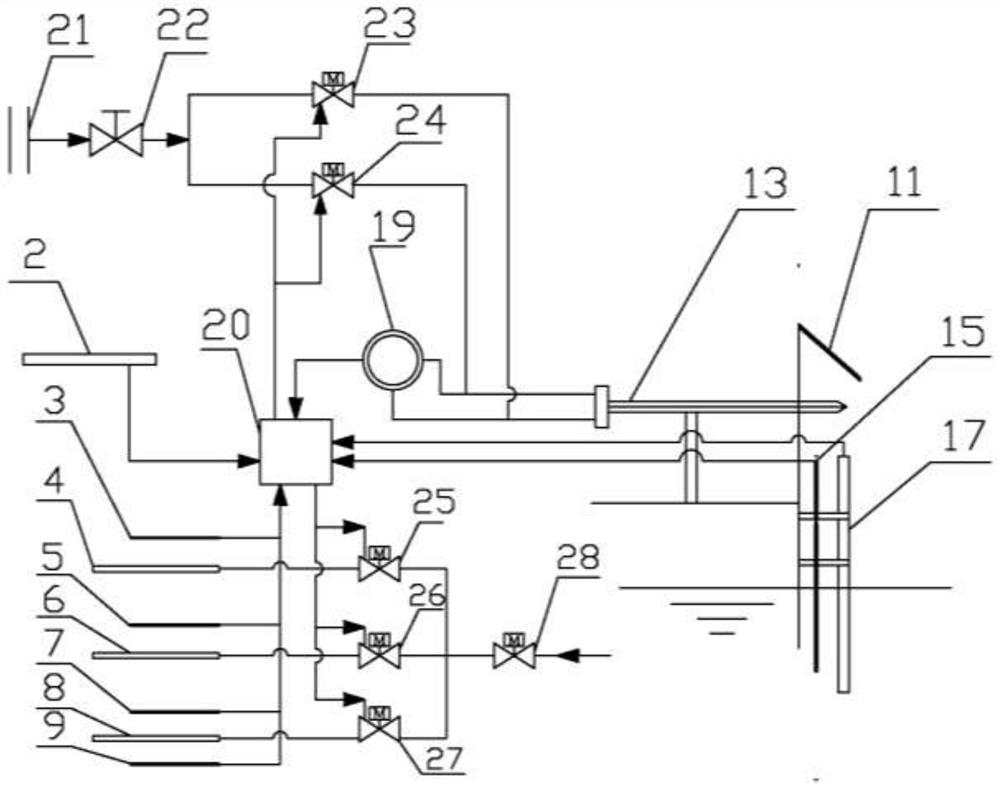

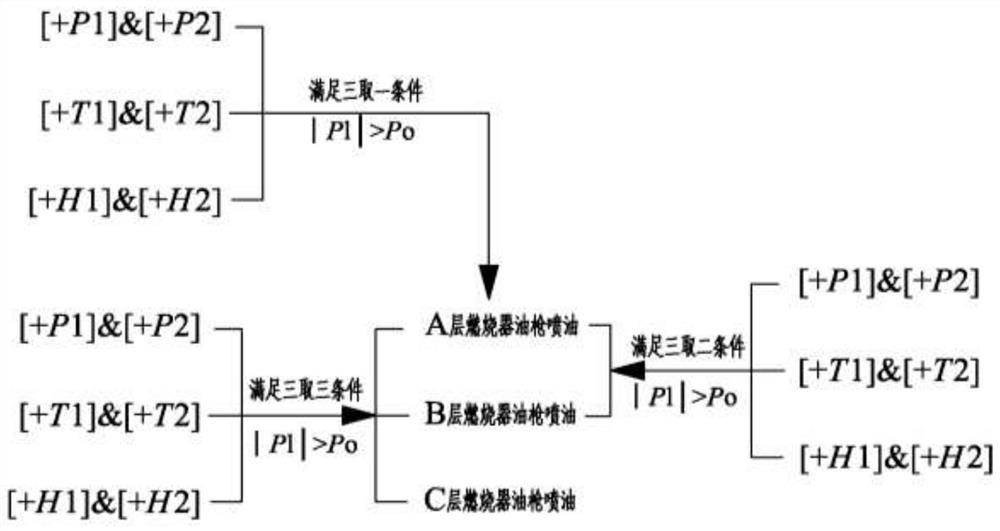

[0037] Unit 1 of a company is a 300MW unit. The boilers are all subcritical parameters, natural circulation drum boilers, single furnace, one-time intermediate reheating, four-corner tangential combustion method, intermediate storage bin type pulverizing system, balanced ventilation, Π-type open air Layout, solid state slag discharge, wet slag removal machine. In June 2014, in conjunction with the unit denitrification renovation project, Zhongjie Huanliwei (Wuhan) Energy Technology Co., Ltd. carried out the boiler low-nitrogen device renovation. Due to the poor quality of coal used, the boiler was seriously coked, and the No. 1 unit had the problem of falling coke and extinguishing fires many time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com