Gas burner

A gas burner and gas pipe technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of low flame temperature, insufficient gas combustion, and unfavorable cost control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

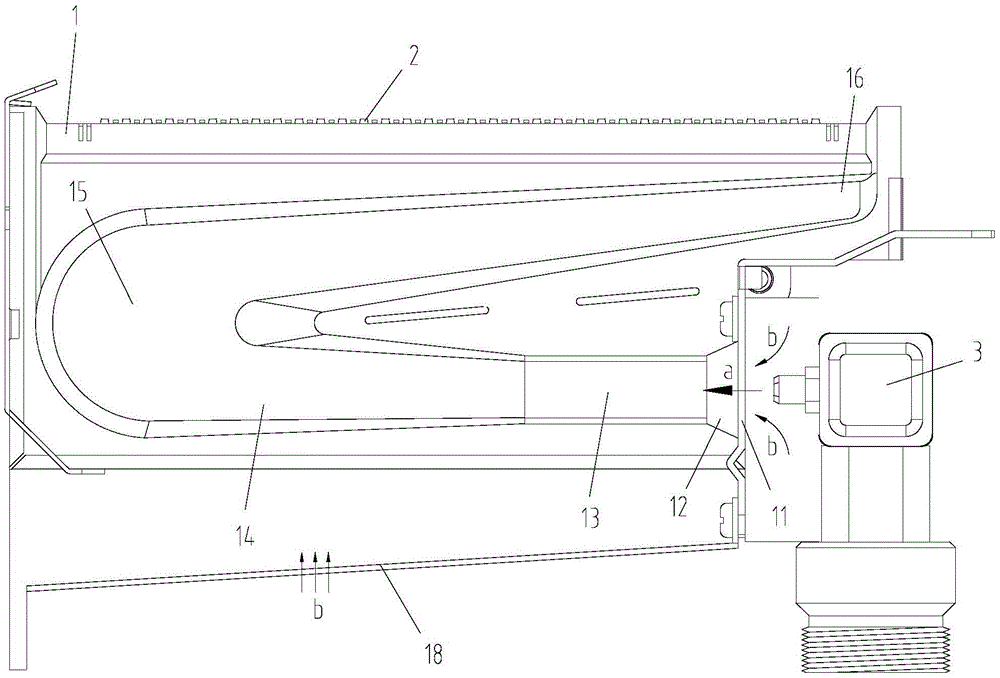

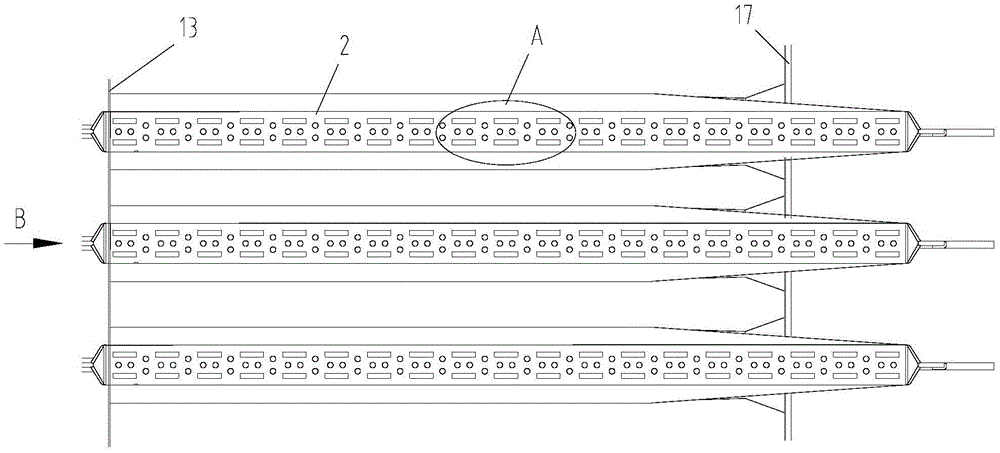

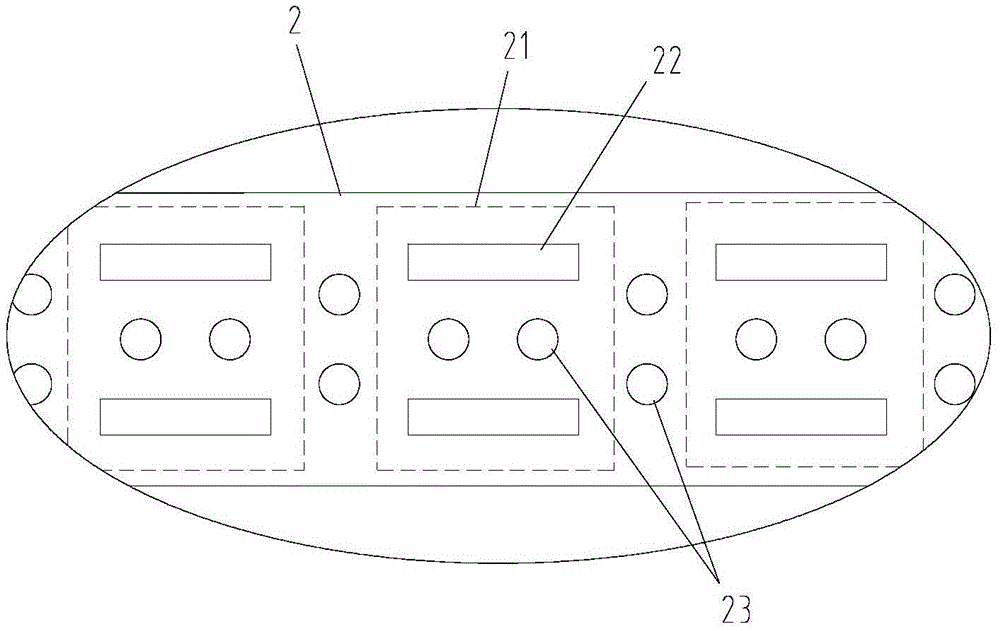

[0021] Embodiments of the present invention are described in detail below:

[0022] like Figure 1-5 As shown, it is a gas burner, which includes a main body frame 1 and a plurality of combustion fire rows 2, and a plurality of combustion fire rows 2 are arranged on the upper end of the main body frame 1 in the same row along the width direction of the combustion fire row 2, The upper end surface of the combustion fire row 2 is provided with a plurality of fire-spraying arrays 21, and the plurality of fire-spraying arrays 21 are at least arranged in one row along the length direction of the combustion fire row 2. The fire-spraying array 21 includes two first nozzles 22 and at least one first nozzle 22. Two nozzles 23, the first nozzle 22 can form the transverse flame 24 towards the surroundings, the second nozzle 23 can form the longitudinal flame 25 towards the top, the two first nozzles 22 are arranged oppositely, the length direction of the first nozzle 22 is aligned with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com