High-voltage breaker permanent magnet salient pole motor operation mechanism and control method

A high-voltage circuit breaker and operating mechanism technology, which is applied to high-voltage air circuit breakers, AC motor control, high-voltage/high-current switches, etc., can solve the problems of incomplete operation process speed, unsatisfactory dynamic control characteristics, and inaccurate tracking. , to achieve the effect of improving the level of intelligent operation, improving the robustness and follow-up control characteristics, and improving the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

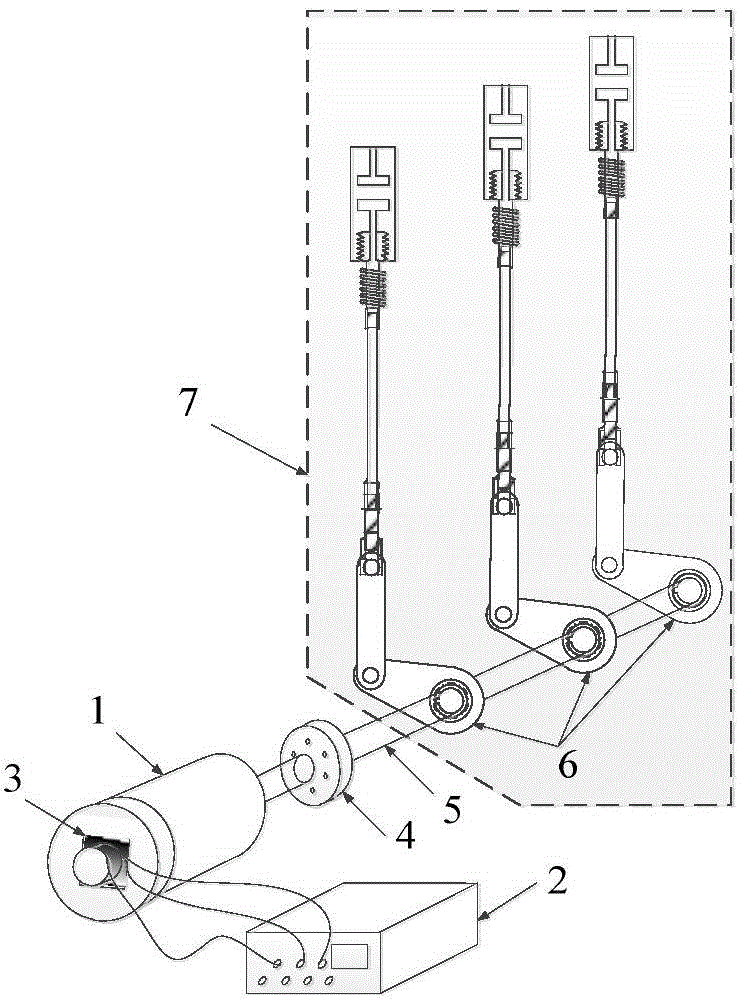

[0045] In this embodiment, the 126kV vacuum circuit breaker is taken as an example. According to the requirements of the arc extinguishing chamber for the operating mechanism, the permanent magnet salient pole motor operating mechanism of the high-voltage circuit breaker is used, such asfigure 1 shown. The operating mechanism is set at the side phase position of the circuit breaker, and is mainly composed of a driving motor 1, a motor controller 2 and a photoelectric encoder 3. In this embodiment, a motor is used to directly drive the transmission mechanism to realize the three-phase mechanical linkage of the circuit breaker.

[0046] The output spindle of the drive motor 1 is connected to the rotating spindle 5 through the docking flange 4, and one end of the three transmission cranks 6 is keyed to the transmission spindle 5, realizing the mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com