System and method for taking slices for bad analysis

A bad, report system technology, applied in the direction of instruments, static indicators, nonlinear optics, etc., can solve the problems of consuming a lot of manpower, not being able to achieve full automation, and lagging in the removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

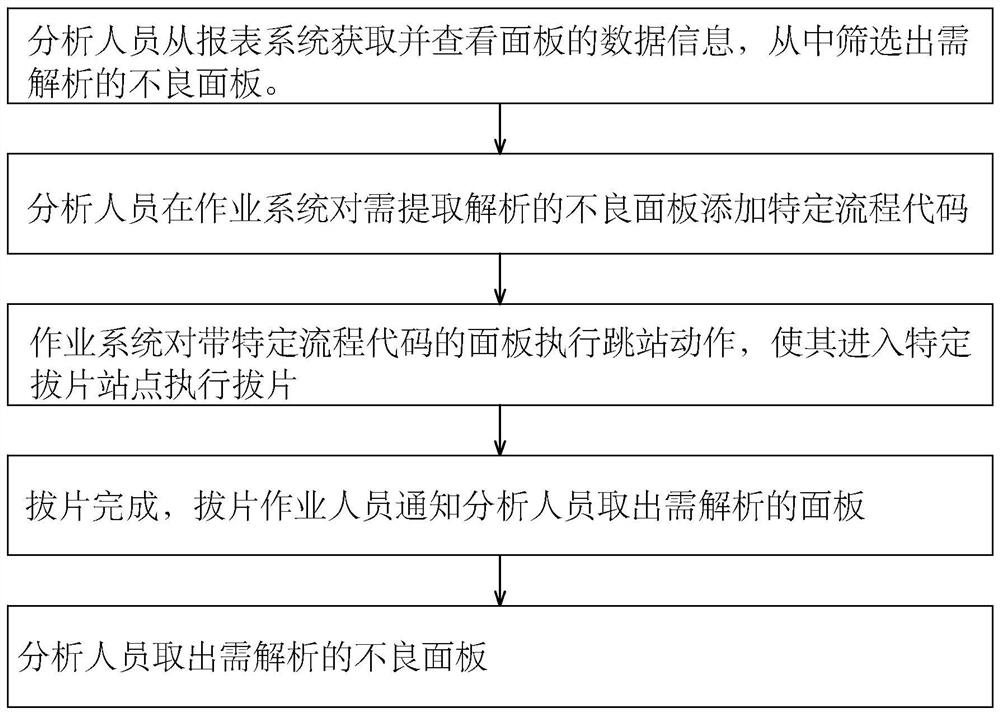

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

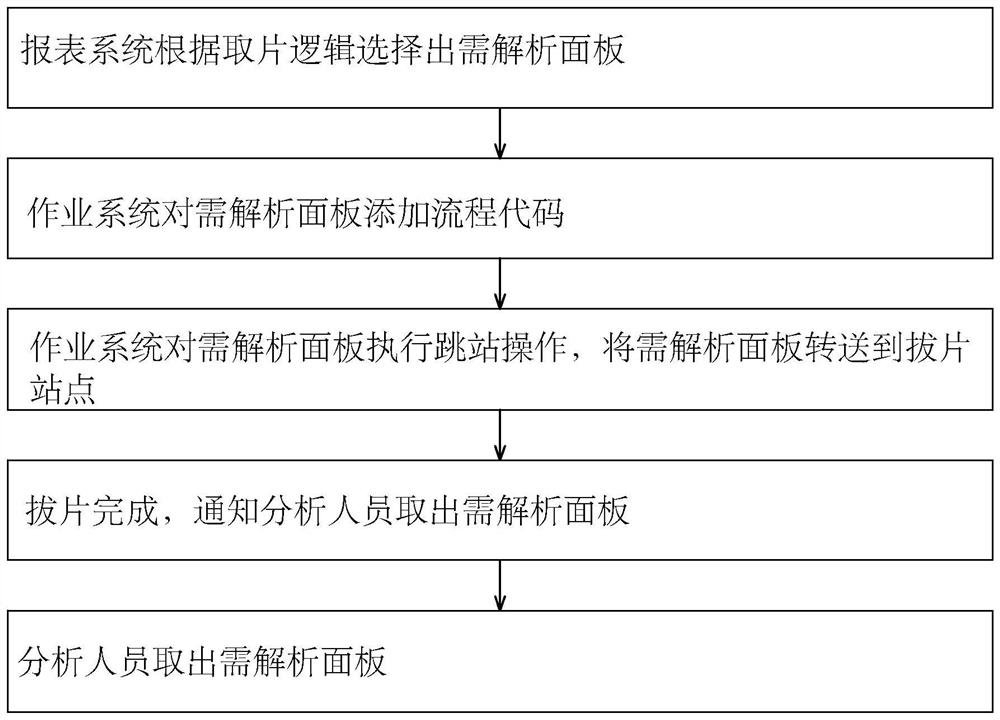

[0032] See figure 2 , the present invention provides a system for taking films for defective analysis, including a report system and an operation system connected in series with the report system; the report system collects and displays panel information on the production line, and the report system collects and displays panel information on the production line. The operating system specifies the flow direction of the panels on the production line; the user inputs slice logic to the report system, and the report system has a built-in logic development module, and the report system uses the logic development module according to the slice logic Select the panel that needs to be parsed, and pass the data information of the panel that needs to be parsed to the operating system. The panels are forwarded to the extraction site.

[0033] Specifically, the system for taking slices for defective analysis further includes a terminal device, the terminal device has a system management ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com