An Atmospheric Pressure Filling Machine Capable of Preventing Dripping and Sucking Back

A filling machine and anti-drip technology, used in liquid bottling, pressure-free perfusion, packaging, etc., can solve problems such as sucking back, and achieve the effect of preventing retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

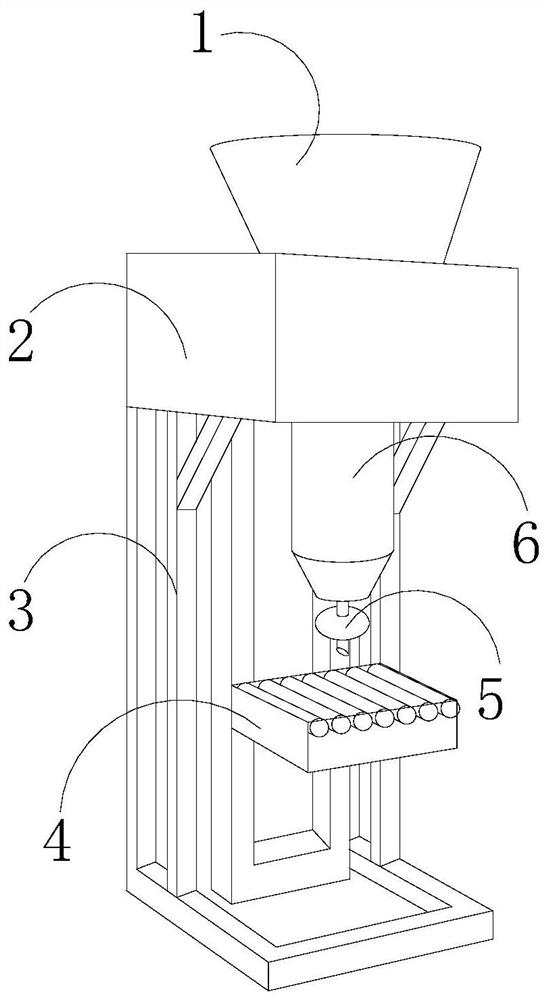

[0028] see Figure 1-Figure 7 , the present invention provides an atmospheric pressure filling machine capable of preventing dripping and sucking back, the structure of which includes a feed hopper 1, a fixed seat 2, a fixed frame 3, a workbench 4, a filling head 5, and a connecting cavity 6. The feed hopper 1 is installed on the fixed seat 2, the feed hopper 1 communicates with the connecting chamber 6, and the bottom of the connecting chamber 6 is provided with a filling head 5, and the filling head 5 is arranged in the north direction of the working table 4 , the filling head 5 is matched with the workbench 4, the fixed frame 3 is mechanically welded with the fixed seat 2, and the fixed frame 3 is fixedly connected with the workbench 4;

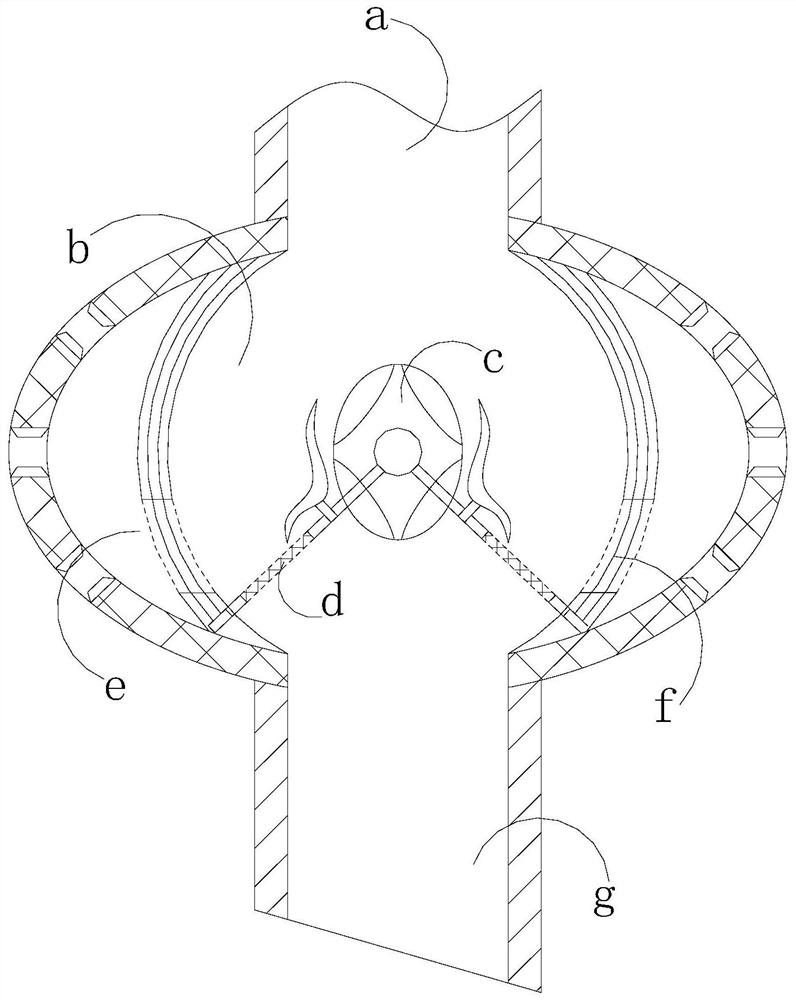

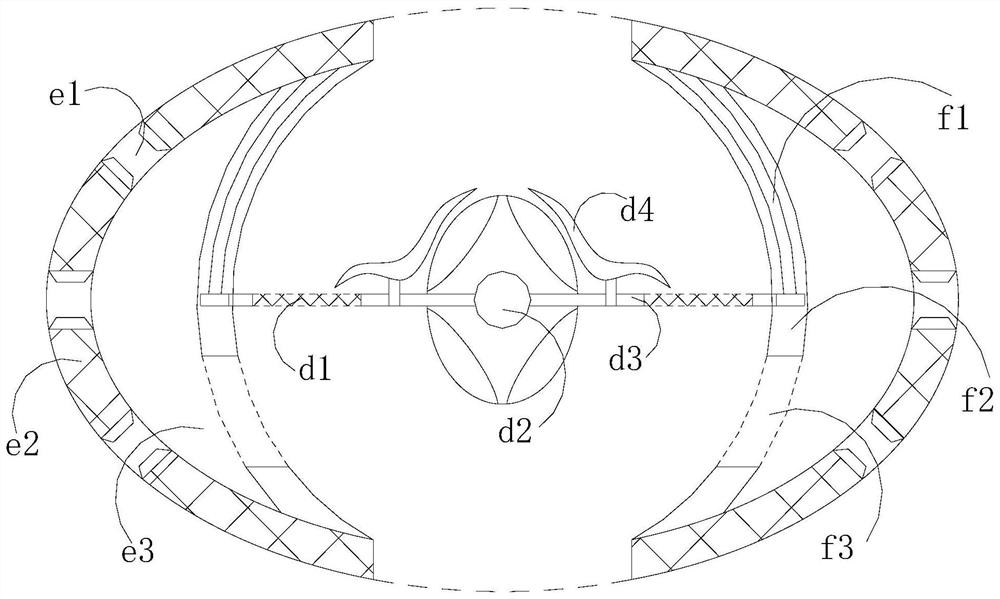

[0029] The filling head 5 is composed of a communication pipe a, a middle chamber b, a fixed block c, a movable plate d, an air pressure balance ring f, a balance ball e, and a filling pipe g. The communication pipe a communicates with the...

Embodiment 2

[0039] see Figure 1-Figure 2 , Figure 4 , Image 6 , the present invention provides an atmospheric pressure filling machine capable of preventing dripping and sucking back, the structure of which includes a feed hopper 1, a fixed seat 2, a fixed frame 3, a workbench 4, a filling head 5, and a connecting cavity 6. The feed hopper 1 is installed on the fixed seat 2, the feed hopper 1 communicates with the connecting chamber 6, and the bottom of the connecting chamber 6 is provided with a filling head 5, and the filling head 5 is arranged in the north direction of the working table 4 , the filling head 5 is matched with the worktable 4, the fixed frame 3 is mechanically welded with the fixed seat 2, and the fixed frame 3 is fixedly connected with the worktable 4; the filling head 5 is composed of the communication pipe a, the middle Cavity b, fixed block c, movable plate d, air pressure balance ring f, balance ball e, and filling pipe g. The fixed block c is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com