Skiving tool

A technology for scraping tools and cutting heads, which can be used in manufacturing tools, gear teeth manufacturing tools, metal processing equipment, etc., and can solve problems such as time-consuming and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

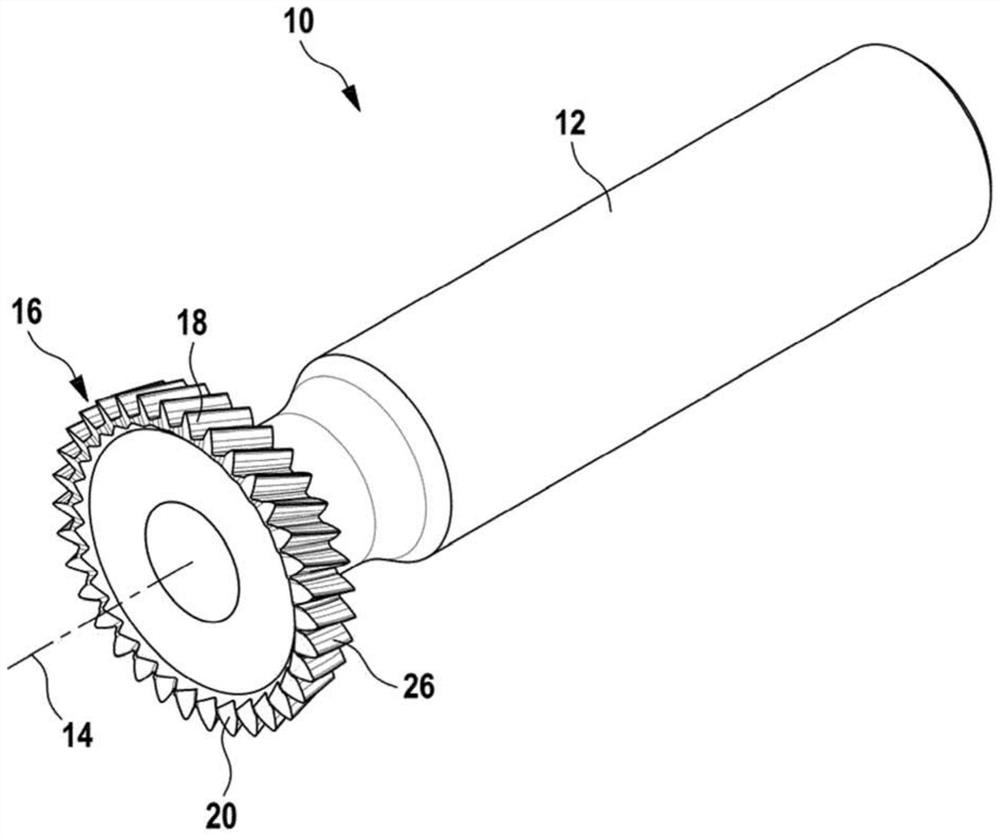

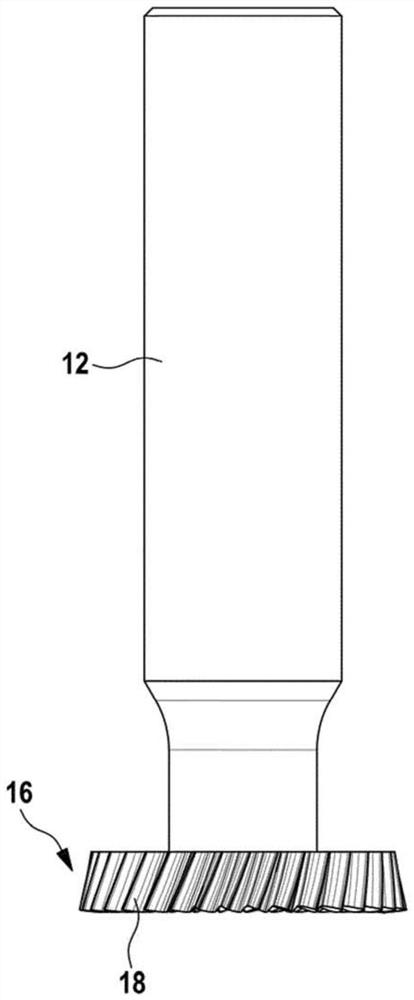

[0044] figure 1 A perspective view of an embodiment of a powered shaving tool according to the invention is shown. The powered scraping tool is generally indicated herein by its reference numeral 10 .

[0045] The powered scraping tool 10 according to the present invention includes a shank 12 extending along a longitudinal axis 14 . In the illustrated embodiment, the handle 12 is cylindrical. In principle, however, the handle 12 can also have a different shape, for example a cuboid.

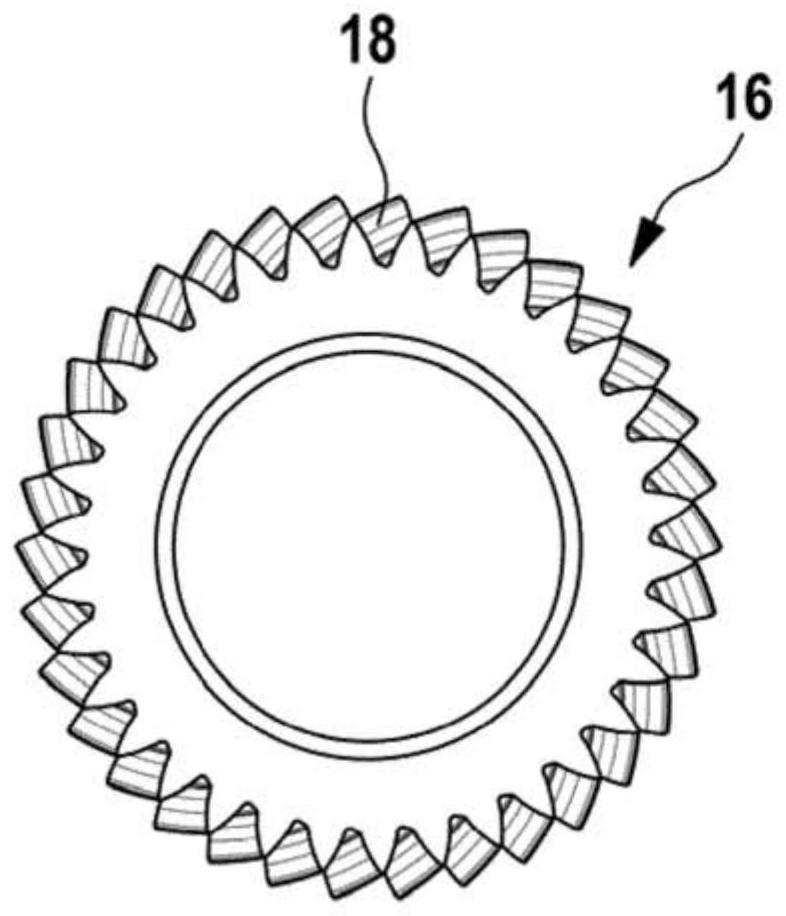

[0046] Furthermore, the powered scraping tool 10 comprises a cutting head 16 arranged at the front end of the shank 12 . A plurality of teeth 18 are arranged on the cutting head 16 , and the plurality of teeth 18 are distributed in the circumferential direction of the cutting head 16 .

[0047] Each of these teeth 18 includes a rake face 20 at the front end of the tooth 18 facing away from the shank 12 . The teeth 18 taper radially outward at an acute angle. Each tooth 18 comprises a circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com