Operating device

A technology of operating equipment and electrical contact, which is applied in the direction of program-controlled manipulators, manufacturing tools, chucks, etc., can solve the problem of high installation cost, and achieve the effect of simplified installation and simple automatic replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

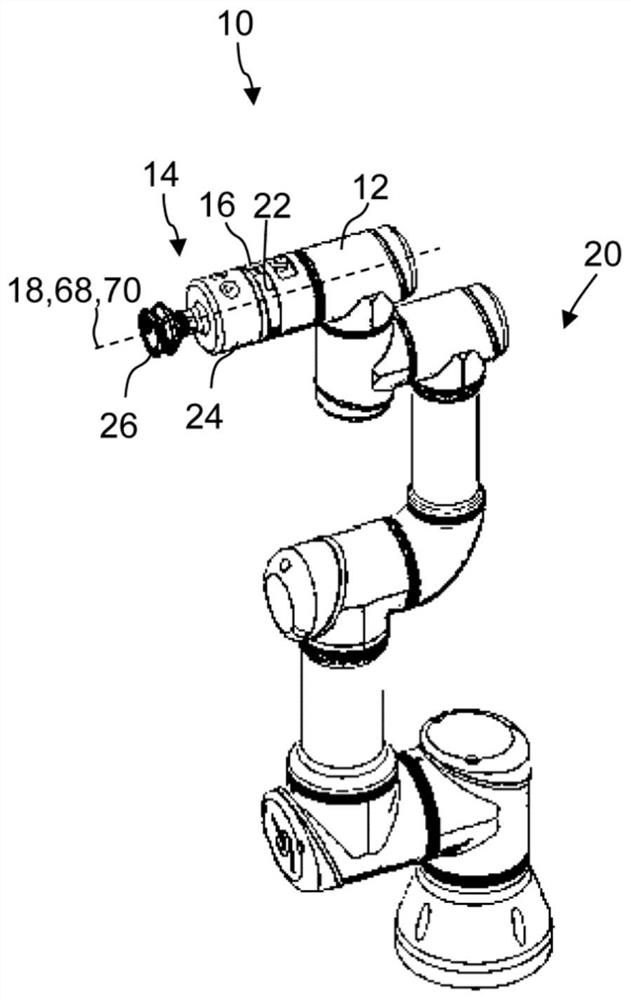

[0050] figure 1 An embodiment of an operating device is shown, which is denoted as a whole by the reference numeral 10 . The operating device 10 includes a robot arm 12 , a grabbing module 13 for grabbing an object (not shown), and a flange plate 16 arranged between the robot arm 12 and the grabbing module 14 .

[0051] The robot arm 12 , the flange plate 16 and the handling module 14 can be connected to each other along a connection axis 18 as will be explained in more detail below.

[0052] In the example shown, the robotic arm 12 is a component of an articulated industrial robot, which is designated as a whole with the reference number 20 . As an example and as a preferred embodiment, the robotic arm 12 is substantially cylindrical and extends along a connection axis 18 . On its axial end facing the flange plate 16, the mechanical arm 12 has, in a known manner per se, an end flange 22 for connecting to the flange plate 16 (see figure 1 ).

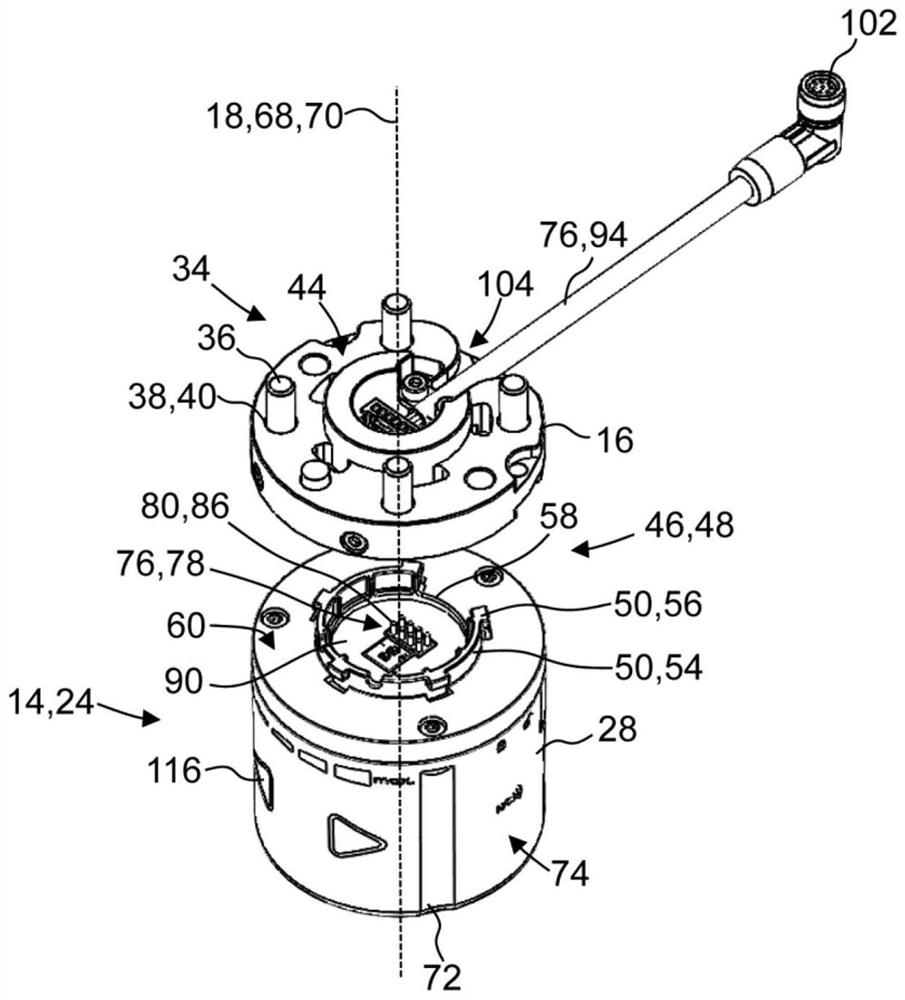

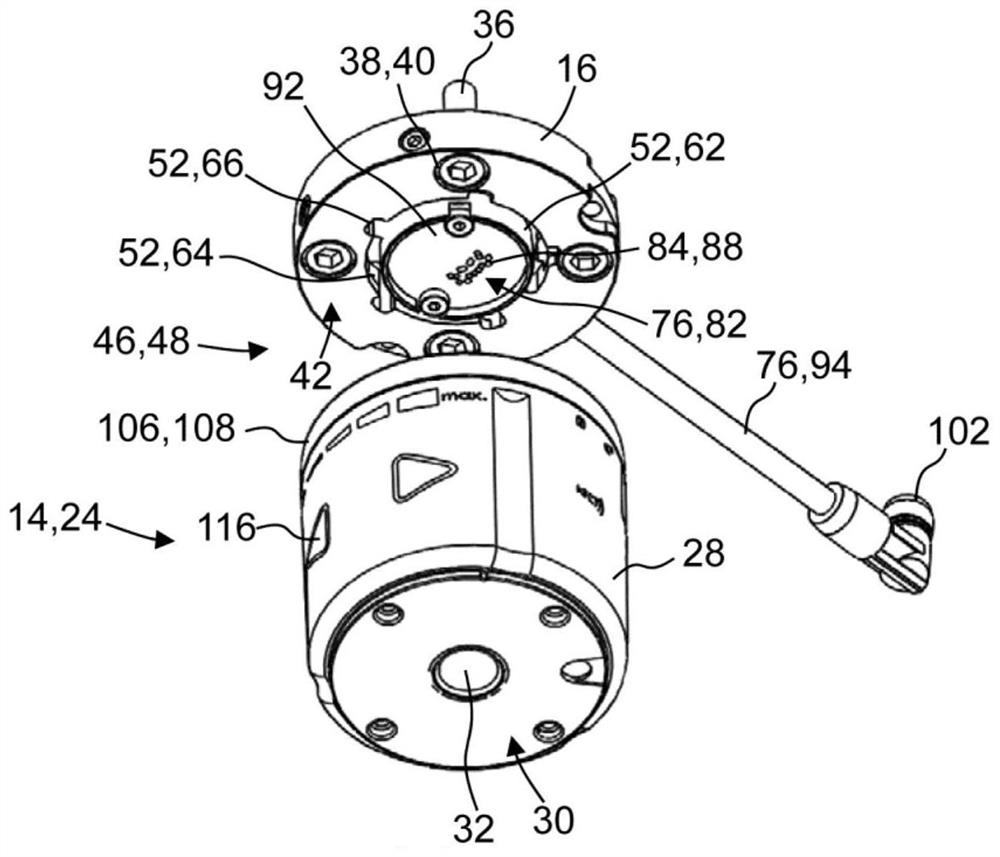

[0053] as from figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com