Environmentally-friendly sand-stone separation device for large-scale sand and soil loading

A sand-stone separation and sand-soil technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of waste of manpower, material resources and time, waste of one process, difficulty in adapting to the changing environment of the transportation site, etc., to save material resources and The effect of manpower, convenient transfer and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

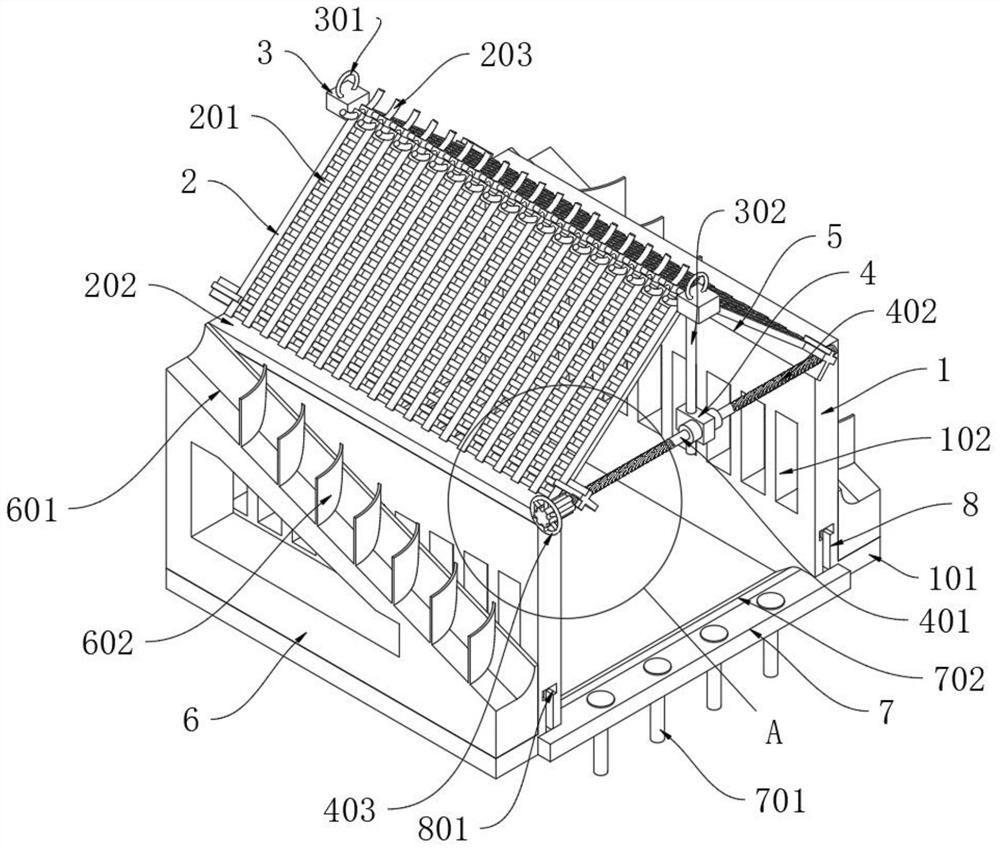

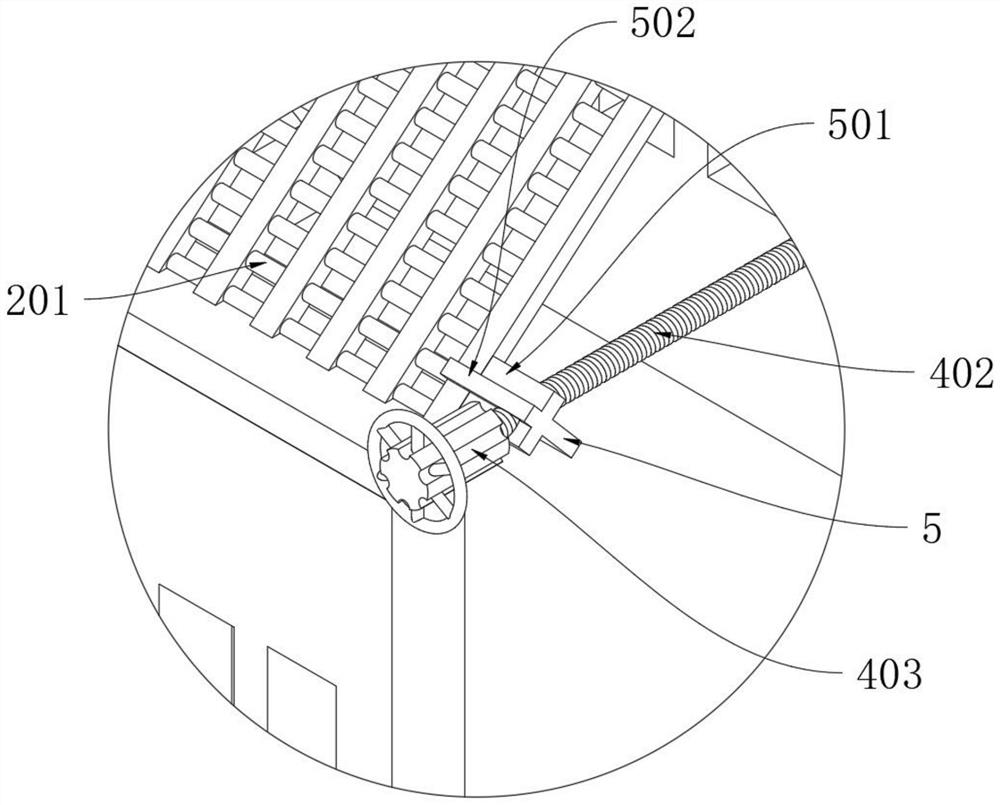

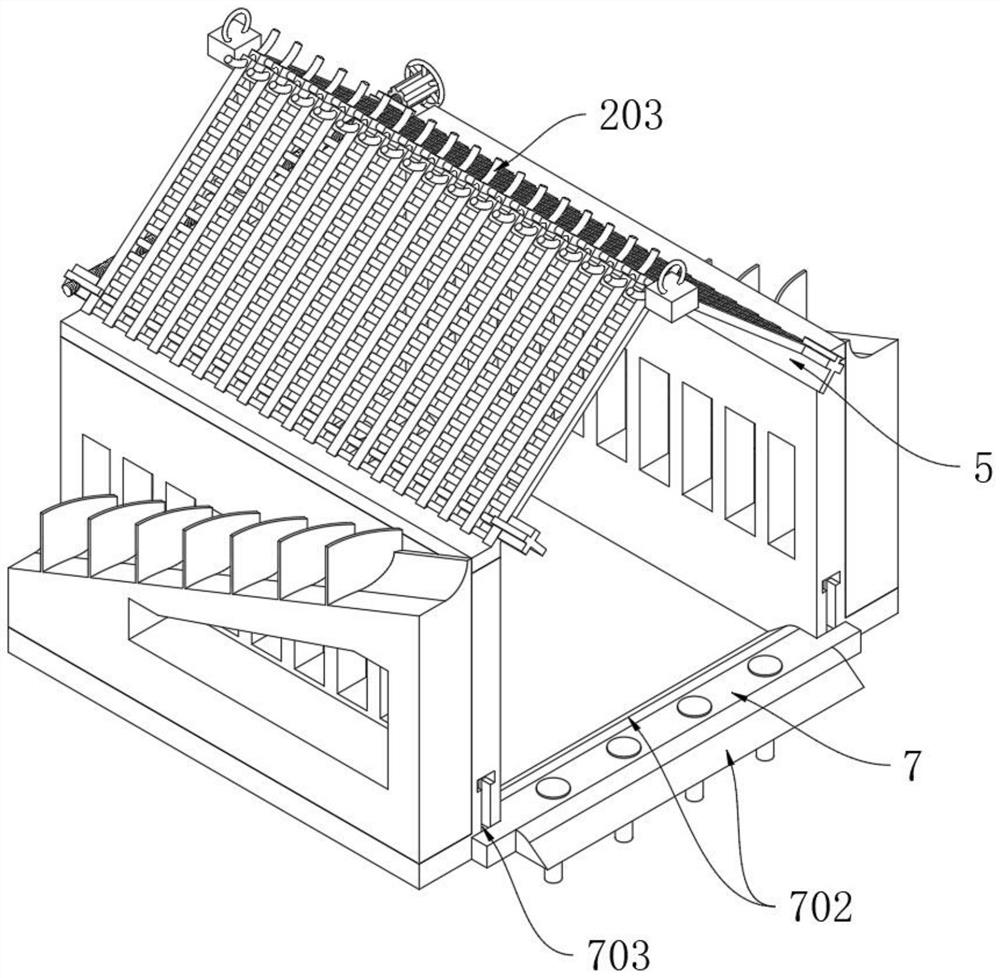

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037] The present invention provides a kind of environment-friendly sand-stone separation device for loading large-scale sand and soil, which includes a stand body 1; two stand bodies 1 are placed parallel to each other and vertically on the ground; the stand body 1 includes a seat plate 101, a grid 102, The positioning column A103 and the positioning groove B104, the lower end edge of the outer wall of the stand body 1 is fixed vertically outward with a seat plate 101 that is tangent to the ground, and the top plane of the seat plate 101 is evenly spaced horizontally. The positioning column A103 of the positioning column A103, and the lower end of the stone dividing mechanism 6 is inserted on the seat plate 101, and the top plane of the stand body 1 is uniformly provided with positioning grooves B104 corresponding to the bottoms at both ends of the separation screen 2, and the stand body 1 The main body is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com