Cutter holder structure

A technology of knife handle and knife bar, which is applied in the field of clamping structure improvement, can solve the problems of limited shrinkage range, increased labor cost, limited application range of elastic collet 82, etc., and achieves the effect of increasing application range and high locking rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

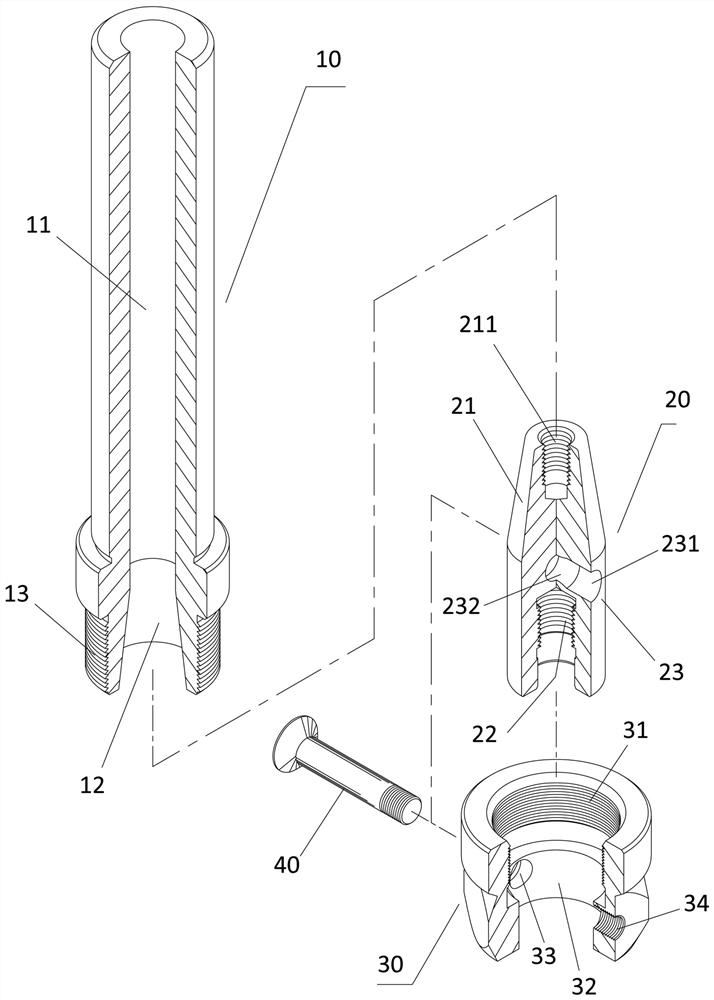

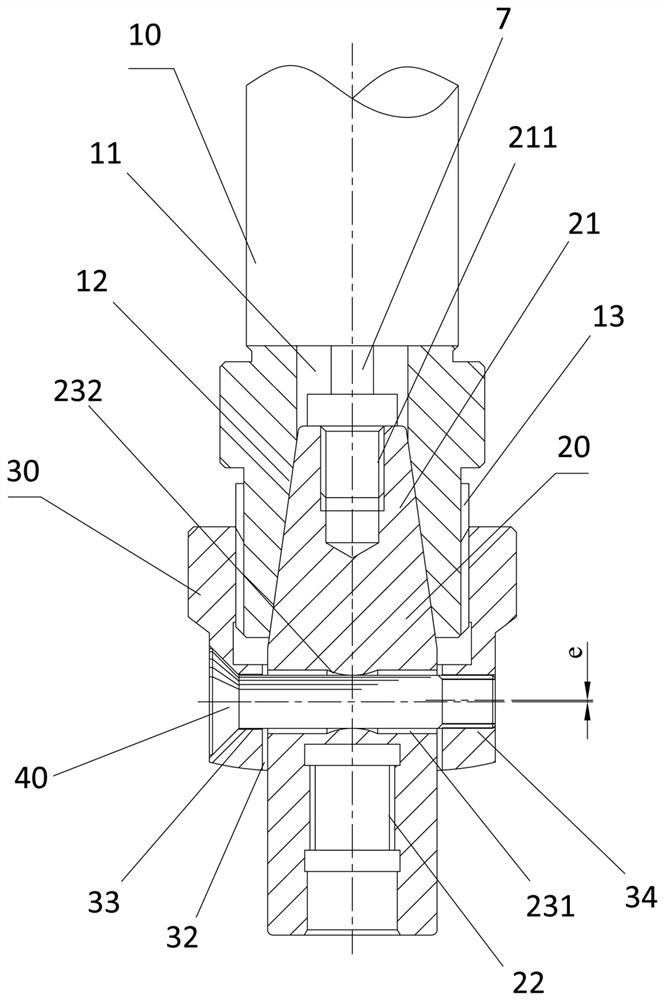

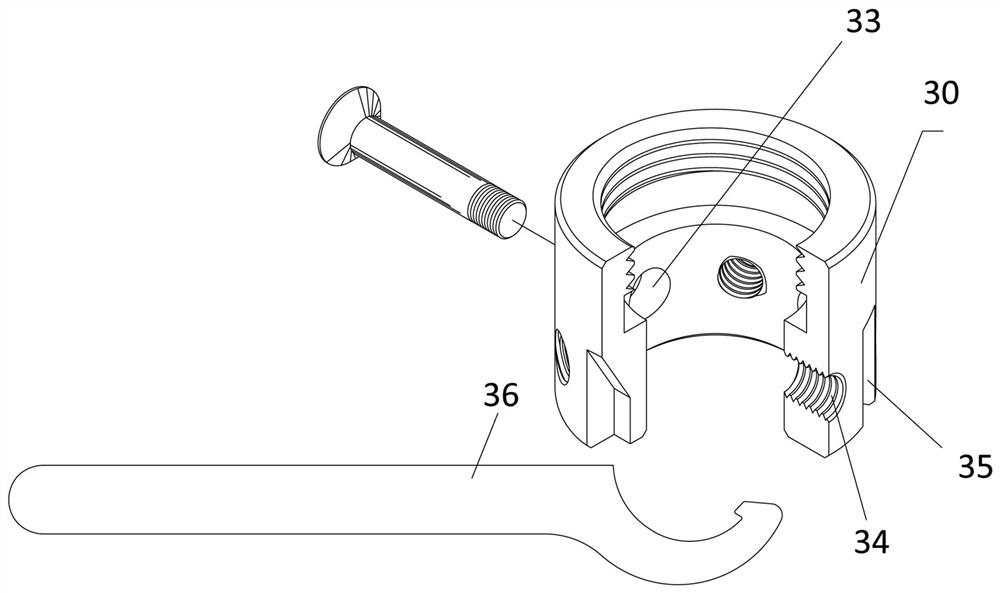

[0014] see figure 1 , 2 As shown, the knife handle structure of the present invention includes a knife bar 10, an adapter bar 20 and a nut 30, wherein:

[0015] Knife bar 10, as general commercially available straight shank knife bar or tapered shank knife bar, is provided with a through hole 11, and this through hole 11 front end is set as an inner tapered hole 12, and one end of this knife bar 10 is provided with outer thread 13;

[0016] Adapter rod 20, one end is provided with a tapered rod 21, and this tapered rod 21 corresponds to the inner tapered hole 12 of cutter bar 10, and the end face of described tapered rod 21 is provided with an inner threaded hole 211, which can be locked by tie rod bolt 7 , the other end of the adapter rod 20 is provided with another internal screw hole 22, which can be used for locking the cutter head 50 of a cutter such as a milling cutter or a drill bit (such as Figure 5 As shown), the adapter rod 20 is adjacent to the tapered rod 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com